MDX V6-3471cc 3.5L (2002)

Alignment: Service and Repair

Preliminary Checks

Wheel Alignment

The suspension can be adjusted for front and rear toe.

Pre-Alignment Checks

For proper inspection and adjustment of the wheel alignment, do these checks:

1. Release the parking brake to avoid an incorrect measurement.

2. Make sure the suspension is not modified.

3. Check the tire size and tire pressure.

Tire size: 235/65 R17 103T

Tire pressure: 220 kPa (2.2 kgf/cm2, 32 psi)

4. Check the runout of the wheels and tires.

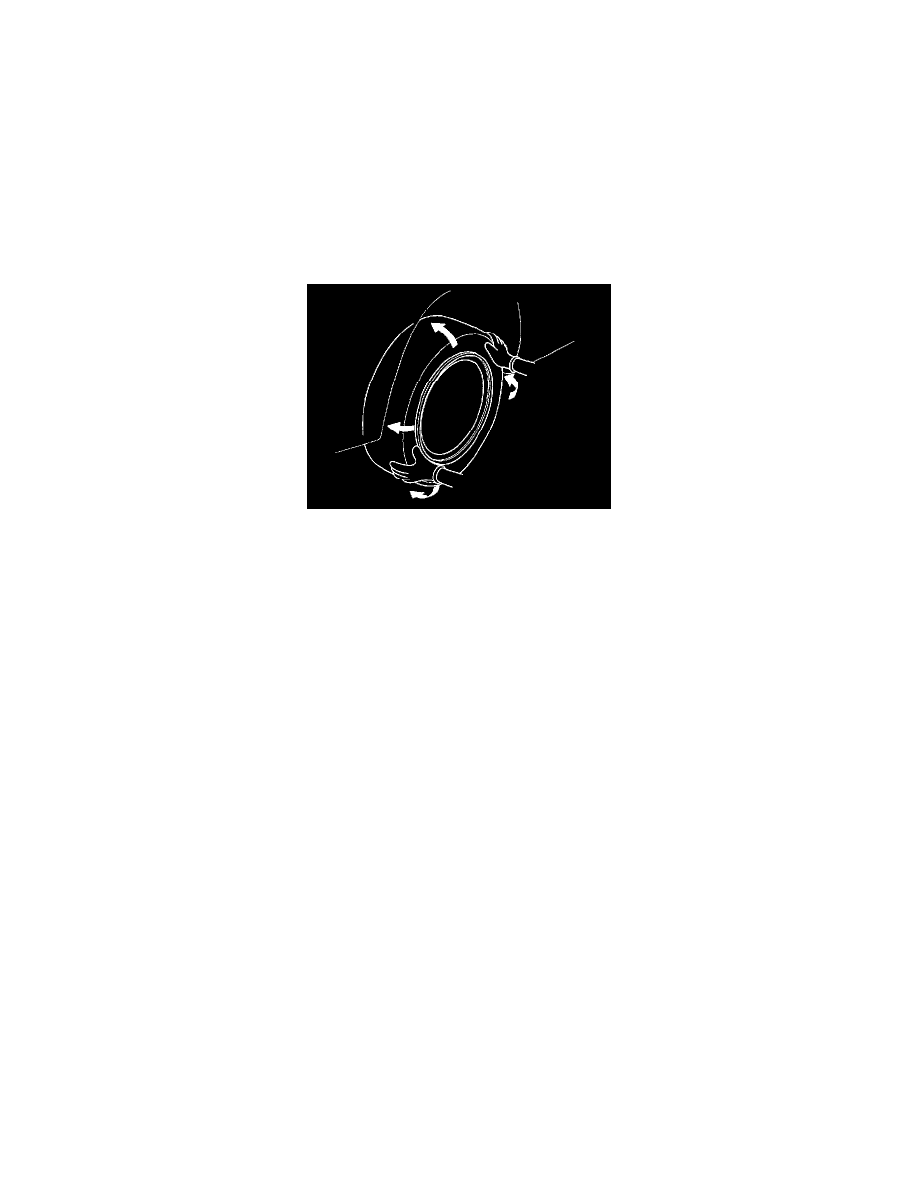

5. Check the suspension ball joints. (Hold a wheel with your hands, and move it up and down and right and left to check for wobbling.)

6. Bounce the suspension up and down several times to stabilize the suspension.

Caster Inspection

Use commercially available computerized four wheel alignment equipment to measure wheel alignment (caster, camber, toe, and/or turning angle).

Follow the equipment manufacturer's instructions.

1. Check the caster angle.

Caster angle: 1°53' ± 1°

2. If out of specification, check for bent or damaged suspension components.

Camber Inspection

Use commercially available computerized four wheel alignment equipment to measure wheel alignment (caster, camber, toe, and/or turning angle).

Follow the equipment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: - 0°30' ± 1°

Rear: - 0°30' ± 45'

2. If out of specification, check for bent or damaged suspension components.

Front Toe Inspection/Adjustment

Use commercially available computerized four wheel alignment equipment to measure wheel alignment (caster, camber, toe, and/or turning angle).

Follow the equipment manufacturer's instructions.

1. Center the steering wheel spokes.

2. Check the toe with the wheels pointed straight ahead.

Front toe: 0 ± 2 mm to 0 ± 1/16 inch)

^

If no adjustment is required, remove the alignment equipment.

^

If adjustment is required, go to step 3.