A1

Note

Note

|

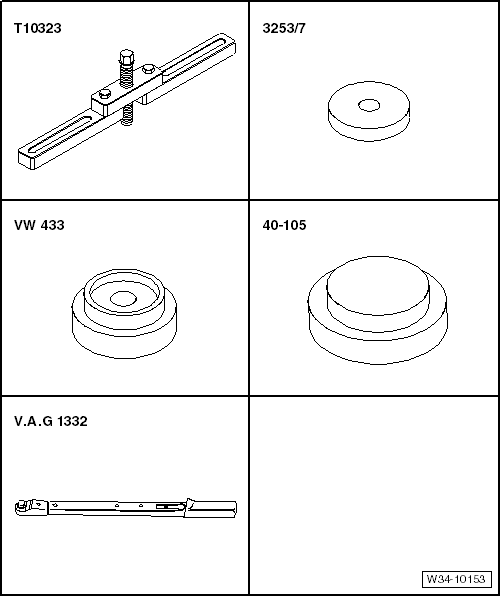

| Special tools and workshop equipment required |

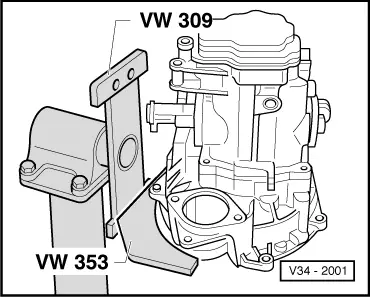

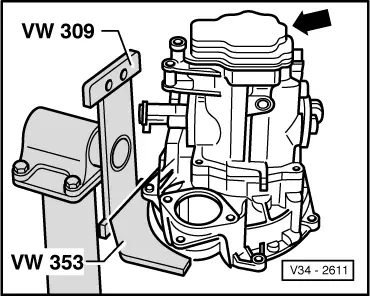

| t | Support plate -VW 309- |

| t | Gearbox support -VW 353- |

| t | Drift -VW 295- |

| t | Drift sleeve -VW 244 B- |

| t | Hot air blower -V.A.G 1416- |

| t | Torque wrench -V.A.G 1331- |

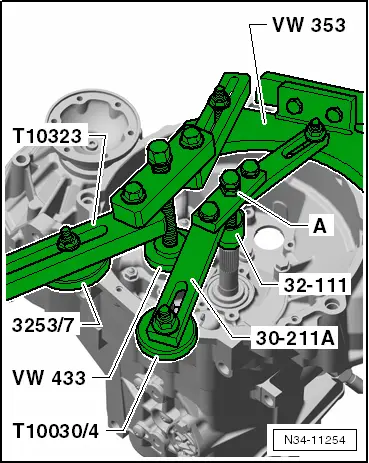

| t | Support bridge -30-211A- |

| t | Thrust piece -32 - 111- |

| t | Thrust piece -T10030/4- |

| t | Thrust piece of assembly tool -T10030/4- |

| t | Tube -VW 416 B- |

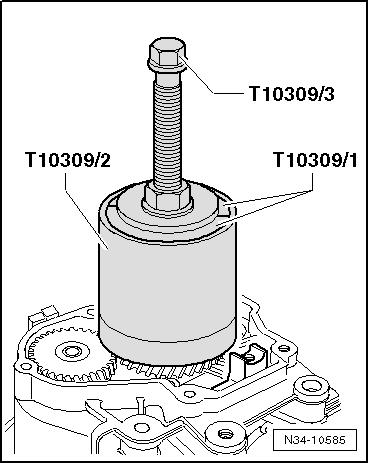

| t | Puller -T10309- |

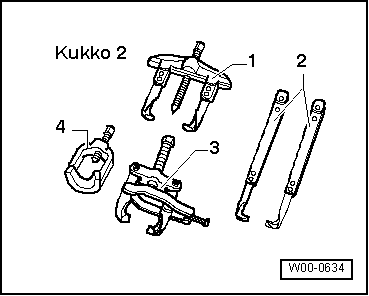

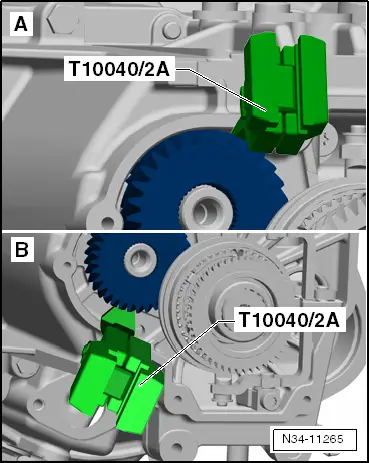

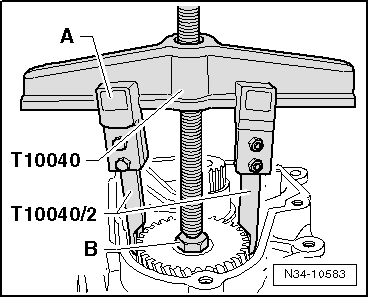

| t | Two-arm puller -T10040- |

| t | With claws -T10040/2A- |

| t | Support bridge -T10323- |

| t | Assembly tool -3253/7- |

| t | Press tool -VW 433- |

| t | Thrust plate -40 - 105- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

|

|

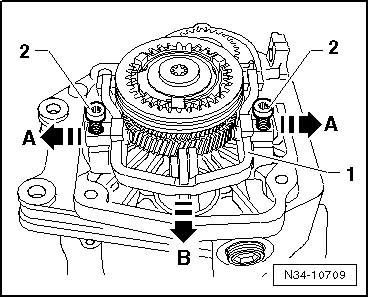

| If claws -T10040/2A- cannot be applied correctly: | |||||||

| -A- Claws -T10040/2A- foul against:

| In this case the 5th gear synchro-hub, 5th gear wheel and gearbox housing have to be removed together → Chapter. | ||||||

| -B- Claws -T10040/2A- foul against ribs in gearbox housing below gear wheel. | |||||||

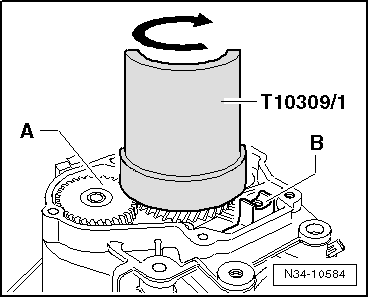

| If claws -T10040/2A- can be applied correctly: | |||

| 5th gear can be removed separately → Fig. |

Note

Note

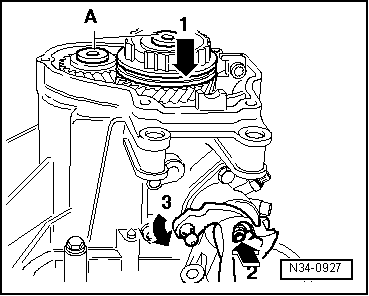

|

|

|

|

|

|

Note

Note

|

|