A1

| Exploded view - servicing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

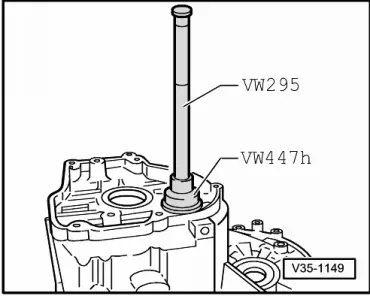

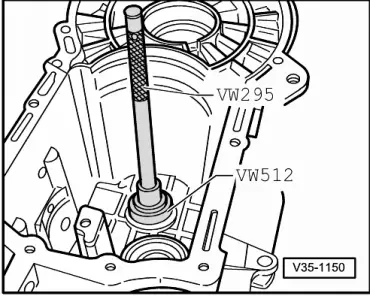

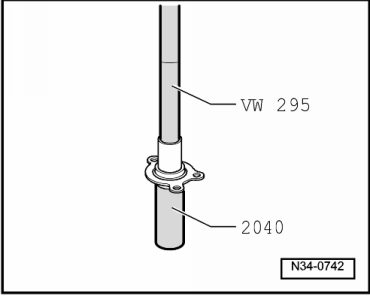

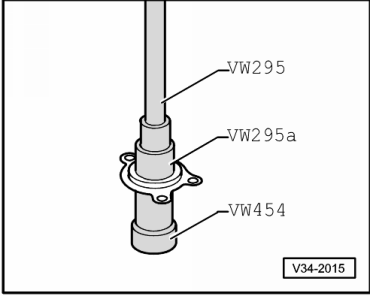

| t | Drift -VW 295- |

| t | Adapter -VW 295 A- |

| t | Thrust plate -VW 447 H- |

| t | Thrust pad -VW 512- |

| t | Press tool -VW 454- |

| t | Tube -2040- |

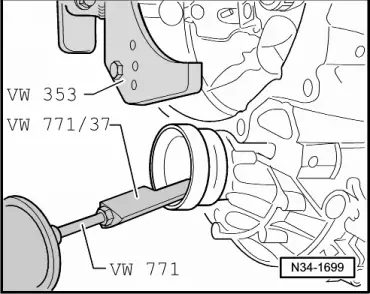

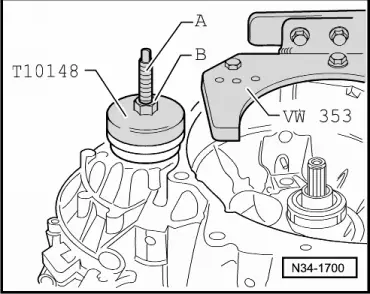

| t | Gearbox support -VW 353- |

| t | Thrust piece -3124- |

| t | Flange shaft oil seal (right-side) - one-piece oil seal and sleeve: |

| t | Spindle from assembly tool -3066- |

| t | Flange shaft oil seal (right-side) - two-piece oil seal and sleeve: |

| t | Thrust piece -T10148- |

| t | Multi-purpose tool -VW 771- |

| t | Extractor hook -VW 771/37- |

| 1 - | Gearbox housing |

| q | If renewed: Adjust input shaft and differential → Chapter |

| 2 - | Needle bearing |

| q | For output shaft |

| q | Removing → Fig. |

| q | Installing and securing → Fig. |

| 3 - | Oil filler plug |

| q | 35 Nm |

| 4 - | Tapered roller bearing outer race |

| q | For output shaft |

| q | Removing and installing → Chapter |

| q | If renewed: Adjust output shaft → Chapter |

| 5 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Chapter |

| 6 - | Shim |

| q | For input shaft |

| q | Table of adjustments → Chapter |

| 7 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Chapter |

| q | If renewed: Adjust input shaft → Chapter |

| 8 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Chapter |

| q | If renewed: Adjust input shaft → Chapter |

| 9 - | Needle bearing |

| q | Removing and installing → Chapter |

| 10 - | Dowel sleeve |

| q | 2x |

| 11 - | Clutch housing |

| q | If renewed: ⇒ table of adjustments → Chapter |

| 12 - | Guide sleeve |

| q | With input shaft oil seal and vulcanised O-ring |

| q | Driving out oil seal → Fig. |

| q | Driving in oil seal → Fig. |

| q | Remove guide sleeve in order to renew oil seal |

| q | Renew guide sleeve if O-ring is damaged |

| 13 - | Socket head bolt |

| q | Removing and installing → Item |

| 14 - | Oil seal |

| q | Not a separate part |

| q | One-piece oil seal and sleeve → Item |

| 15 - | Sleeve |

| q | Not a separate part |

| q | One-piece oil seal and sleeve → Item |

| 16 - | One-piece oil seal and sleeve |

| q | If oil seal is damaged, renew both sleeve and oil seal |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 17 - | Oil drain plug |

| q | 35 Nm |

| q | Without magnet |

| 18 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pressing out and pressing in → Chapter |

| q | If renewed: adjust differential → Chapter |

| 19 - | Magnet |

| q | Held in place by joint surface of housing |

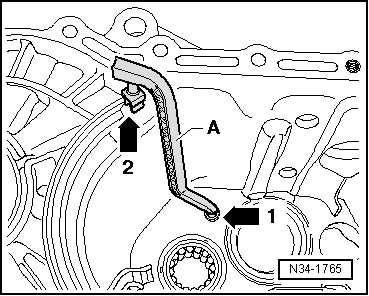

| 20 - | Oil collector |

| q | Not fitted on all versions |

| q | Installing oil collector in gearbox housing → Fig. |

| 21 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pressing out and pressing in → Chapter |

| q | If renewed: adjust differential |

| → Chapter |

| 22 - | Shim |

| q | For differential |

| q | Table of adjustments → Chapter |

| 23 - | Oil seal |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|