A1

| Exploded view - input shaft |

Note

Note| t | Refer to → Electronics parts catalogue and technical data when installing new gear wheels or a new input shaft. |

| t | Pressing input and output shaft out of bearing mounting and grooved ball bearings → Chapter |

| t | Lubricate all bearings, selector gears and synchro-rings on input shaft with gear oil before installing. |

| t | Do not interchange synchro-rings. When re-using synchro-rings, always fit on the same selector gear. |

| 1 - | Input shaft |

| 2 - | Needle bearing |

| q | For 3rd gear |

| 3 - | 3rd speed selector gear |

| 4 - | 3rd gear synchro-ring |

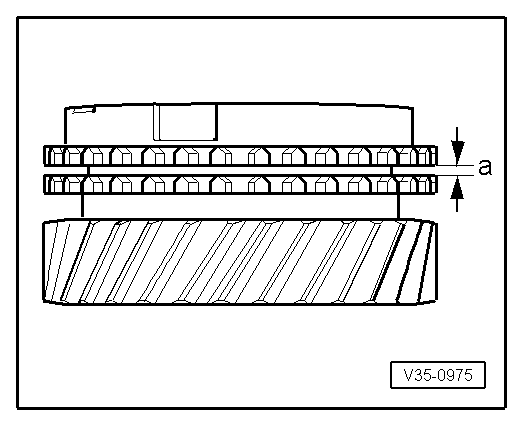

| q | Checking for wear → Fig. |

| 5 - | Locking collar with synchronising hub for 3rd and 4th gear |

| q | Removing and installing → Chapter |

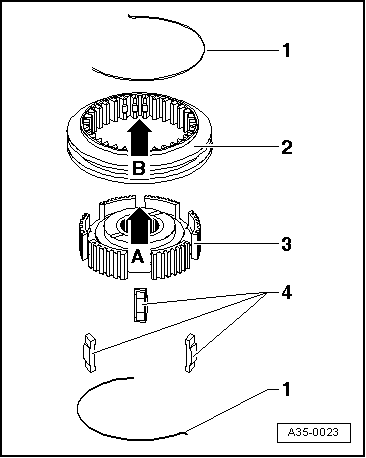

| q | Dismantling and assembling → |

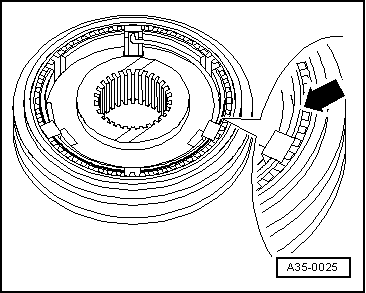

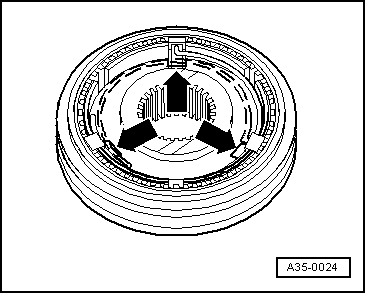

| q | Installation position: Locking collar/synchronising hub → Fig. |

| 6 - | 4th gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Checking for wear → Fig. |

| 7 - | Sleeve |

| q | For 4th gear needle bearing |

| q | Removing and installing → Chapter |

| q | Renew together with → Item |

| 8 - | Needle bearing |

| q | For 4th gear |

| q | Removing and installing → Chapter |

| q | Renew together with → Item |

| 9 - | 4th speed selector gear |

| 10 - | Thrust washer |

| 11 - | Inner race for roller bearing |

| q | Removing and installing → Chapter |

| 12 - | Circlip |

| q | Renew |

| q | Determining thickness → Anchor |

| 13 - | Roller bearing |

| q | With circlip |

| q | Removing and installing → Chapter |

| 14 - | Spring |

| q | Installation position: angled end of spring must locate in one of the locking pieces. |

| 15 - | Locking collar for 3rd and 4th gear |

| q | Dismantling and assembling → |

| q | Installation position: Locking collar/synchronising hub → Fig. |

| 16 - | Synchronising hub for 3rd and 4th gear |

| 17 - | Locking pieces |

| q | 3x |

| 18 - | Spring |

| q | Installation position: angled end of spring must locate in one of the locking pieces. |

|

|

| Gap -a- | Installation depth | Wear limit |

| 3rd and 4th gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|