| –

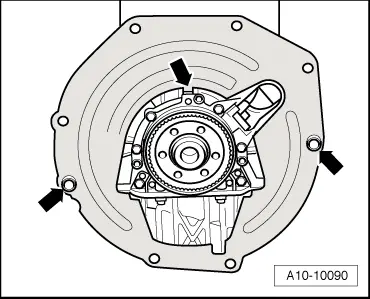

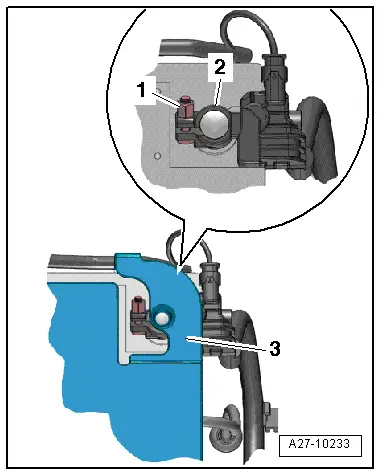

| Align the engine/gearbox assembly in installation position. To do so, raise engine/gearbox until gearbox bracket makes full contact with gearbox mounting. |

Caution | The threads in the gearbox bracket can be damaged if the bolts are not inserted straight. |

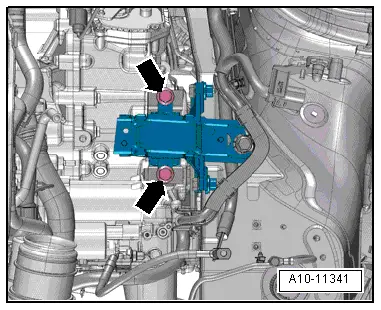

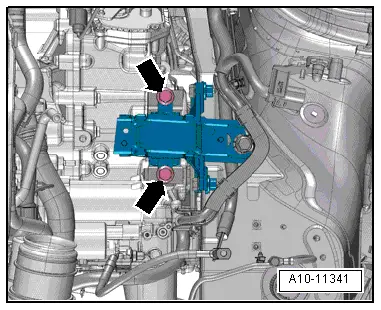

| Before fitting the bolts -arrows-, the gearbox bracket and the gearbox mounting must be aligned so they are parallel. If necessary, press gearbox up with engine and gearbox jack. |

|

| –

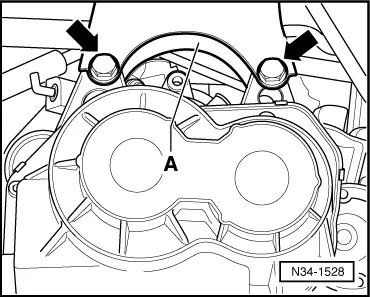

| Bolt gearbox bracket to gearbox mounting → Chapter. |

WARNING | Do not remove support bracket -10 - 222 A- until all bolts securing the left-hand engine/gearbox mounting have been tightened to the specified torque. |

|

|

|

|

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING