A1

| Dismantling and assembling input shaft |

| Special tools and workshop equipment required |

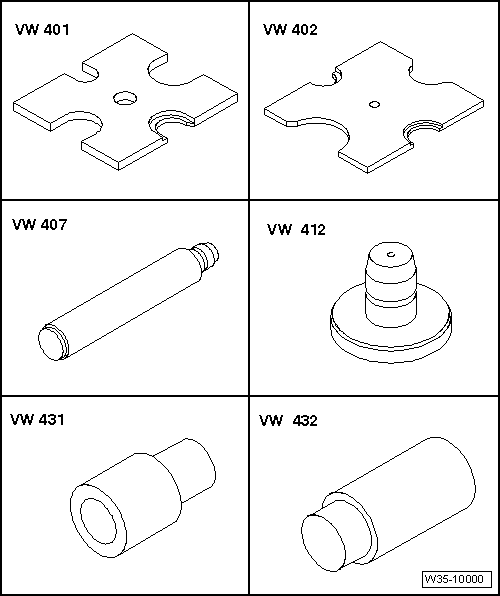

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

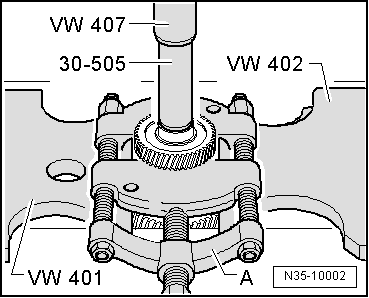

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

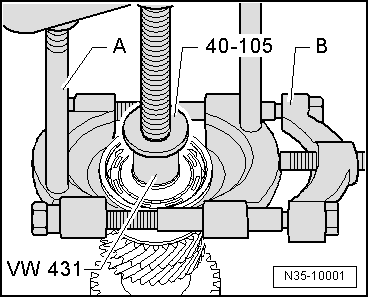

| t | Thrust piece -VW 431- |

| t | Thrust piece -VW 432- |

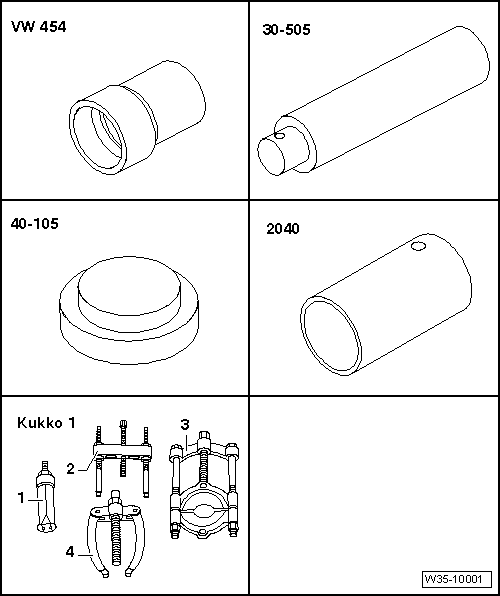

| t | Press tool -VW 454- |

| t | Press tool -30–505- |

| t | Thrust plate -40-105- |

| t | Tube -2040- |

| t | -1-Internal puller -Kukko 21/5- |

| t | -2-Puller -Kukko 18/1- |

| t | -3-Splitter -Kukko 17/1- |

| t | -3-Splitter -Kukko 17/2- |

| t | -4-Counter-support -Kukko 22/2- |

Note

Note| Lubricate all bearings on input shaft with gear oil before installing. |

| 1 - | Circlip |

| q | For grooved ball bearing on input shaft → Item |

| q | Removing and installing → Chapter |

| 2 - | Shim |

| q | Outside diameter = 78.6 mm |

| q | Can only be fitted on modified gearbox housing (from gearbox manufacturing date 10 04 6 to 20 01 8) → Chapter |

| q | Select correct components from → Electronic parts catalogue |

| 3 - | Gearbox housing |

| q | From gearbox manufacturing date 10 04 6 to 20 01 8: modified in area of seat for grooved ball bearing → Item to match shims → Item and → Item → Chapter |

| q | From gearbox manufacturing date 21 01 8 onwards, grooved ball bearing and bearing seat have flattened sides → Chapter |

| q | Select correct components from → Electronic parts catalogue |

| 4 - | Shim |

| q | Outside diameter = 85 mm |

| q | Can only be fitted on modified gearbox housing (from gearbox manufacturing date 10 04 6 to 20 01 8) → Chapter |

| q | Select correct components from → Electronic parts catalogue |

| 5 - | Circlip |

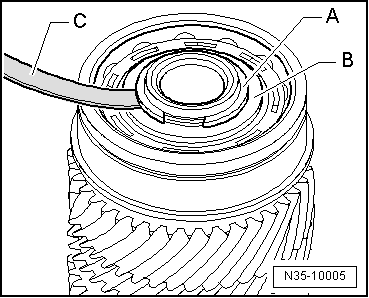

| q | When grooved ball bearing → Item or input shaft → Item are renewed: determine thickness of required circlip → Fig. |

| 6 - | Grooved ball bearing |

| q | Always renew |

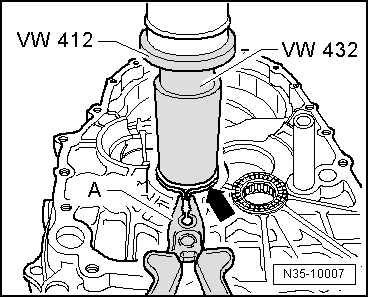

| q | Pulling off → Fig. |

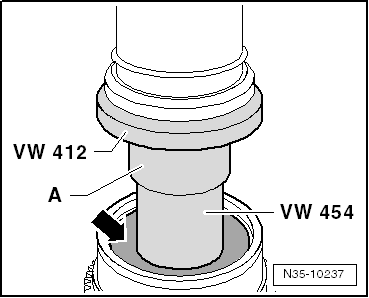

| q | Installation position → Fig. |

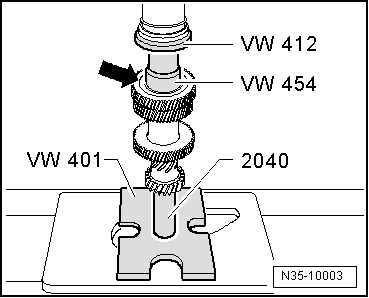

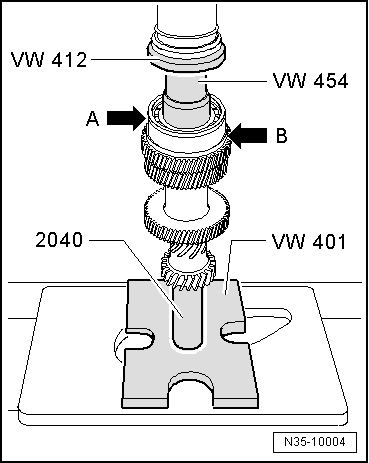

| q | Pressing on → Fig. |

| q | From gearbox manufacturing date 21 01 8 onwards, grooved ball bearing and bearing seat have flattened sides → Chapter |

| 7 - | 5th gear wheel |

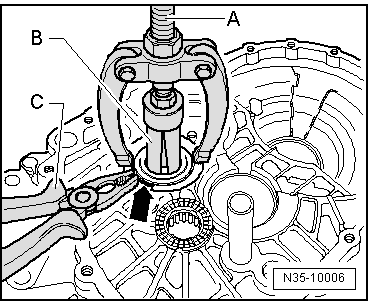

| q | Pressing off → Fig. |

| q | Installation position: Circular slot -arrow- faces towards grooved ball bearing → Item |

| q | Pressing on → Fig. |

| 8 - | Input shaft |

| q | With 3rd/4th and 6th gear wheels |

| 9 - | Roller bearing |

| q | With circlip |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Installation position: Circlip in bearing faces towards input shaft |

| 10 - | Clutch housing |

|

|

|

|

|

|

|

|

Note

Note

|

|

| Measured value (mm) | Circlip thickness (mm) | Axial clearance (mm) |

| 0.01 … 0.05 | 1.86 | 0.01 … 0.05 |

| 0.05 … 0.07 | 1.89 | 0.01 … 0.05 |

| 0.07 … 0.10 | 1.92 | 0.01 … 0.05 |

| 0.10 … 0.13 | 1.95 | 0.01 … 0.05 |

| 0.13 … 0.16 | 1.98 | 0.01 … 0.05 |

|

|

|

|