Camshaft Timing Chain Replacement for 4-Cylinder Petrol Engine

| Removing and installing camshaft timing chain |

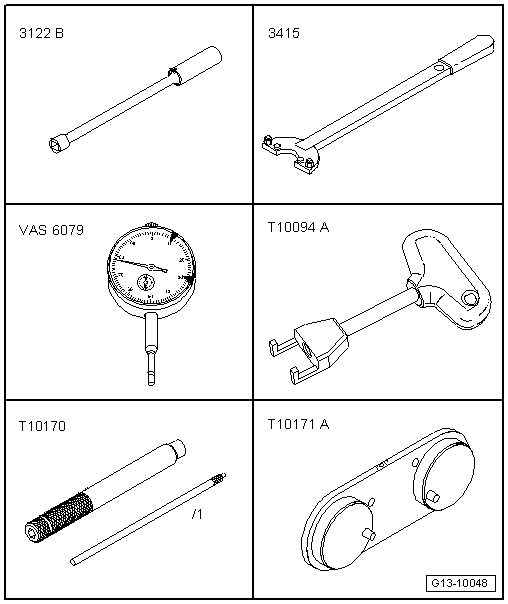

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

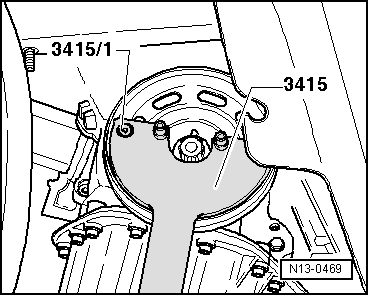

| t | Counterhold tool -3415- with pins -3415/1- |

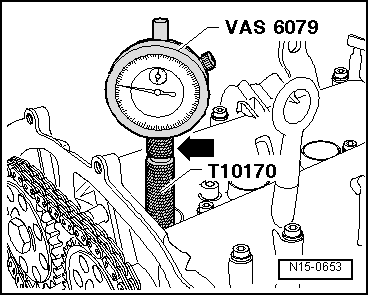

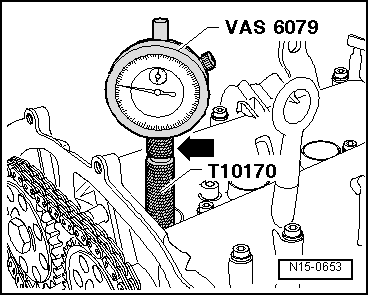

| t | Dial gauge -VAS 6079- |

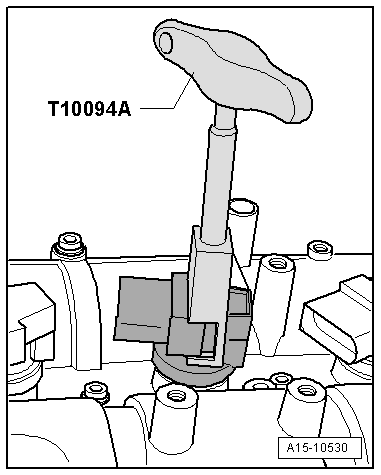

| t | Puller -T10094 A- |

| t | Adapter for dial gauge -T10170- |

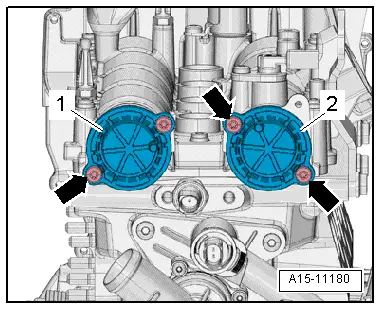

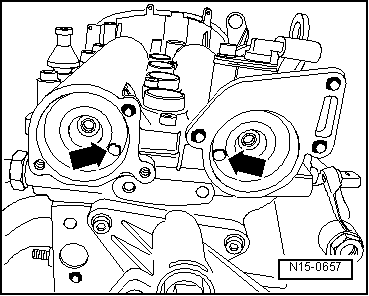

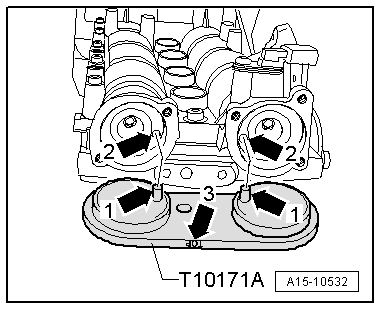

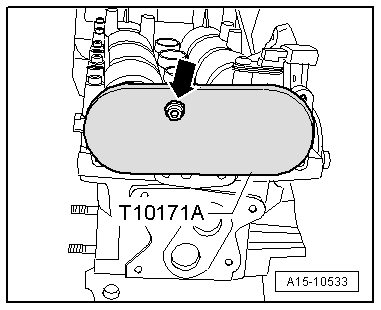

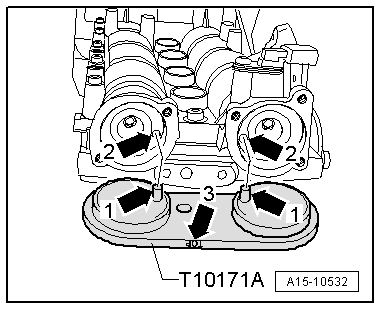

| t | Camshaft clamp -T10171 A- |

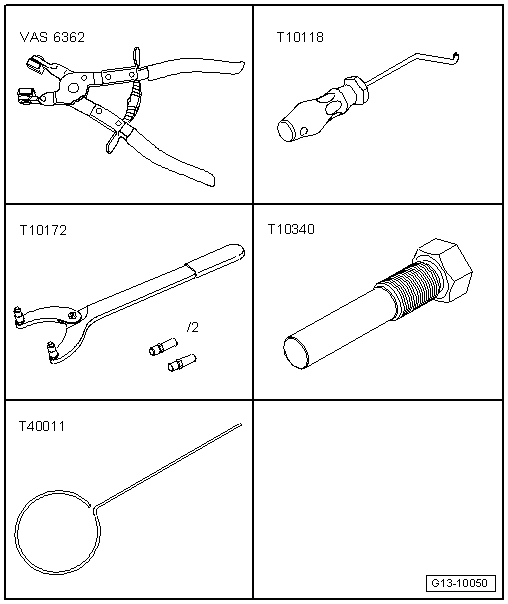

| t | Hose clip pliers -VAS 6362- |

| t | Assembly tool -T10118- |

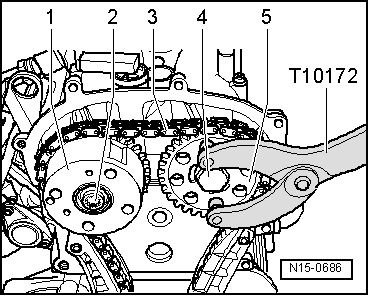

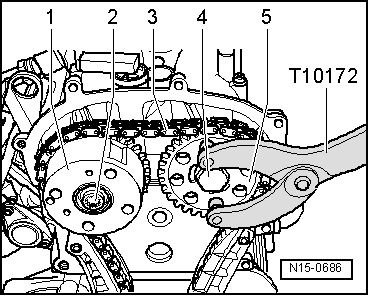

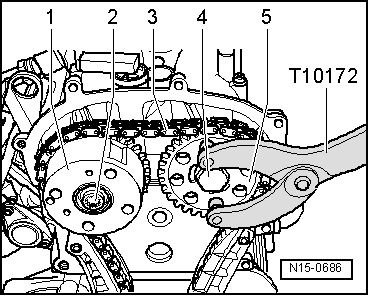

| t | Counterhold tool -T10172- |

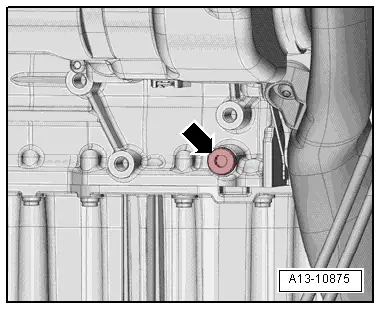

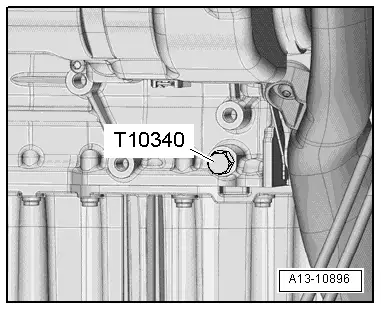

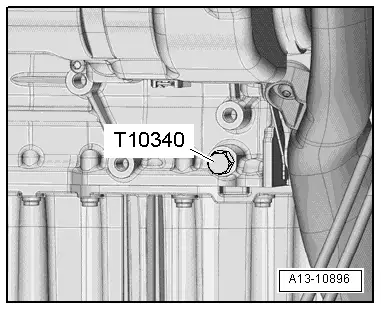

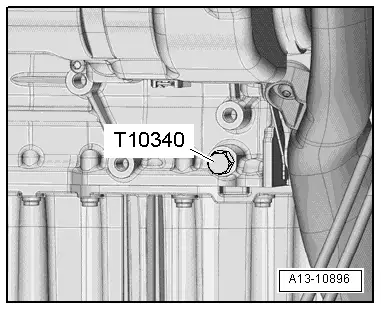

| t | Locking pin -T10340- |

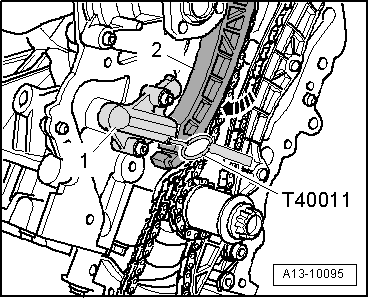

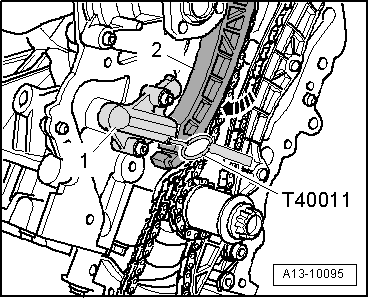

| t | Locking pin -T40011- |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Caution

Caution