| –

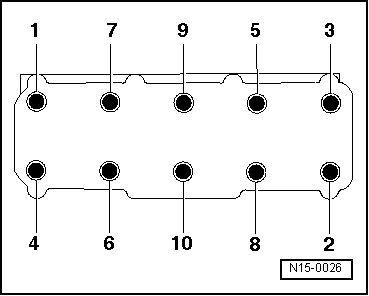

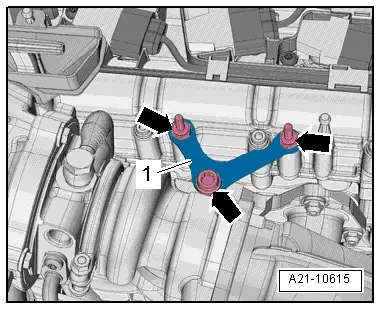

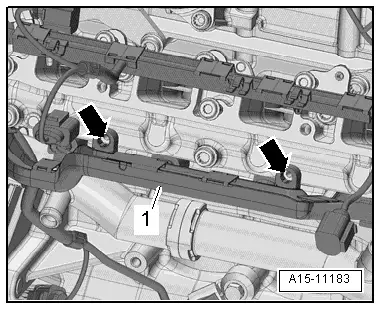

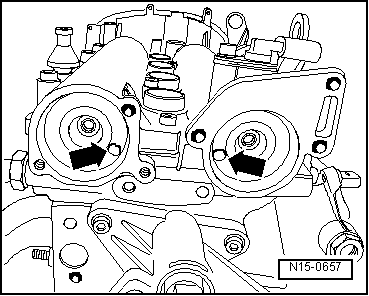

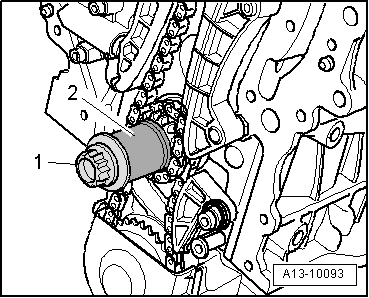

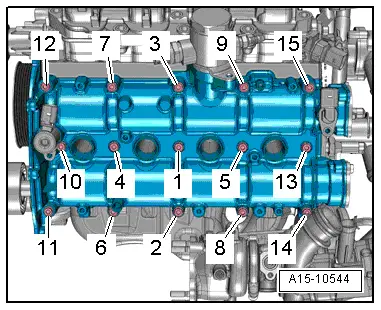

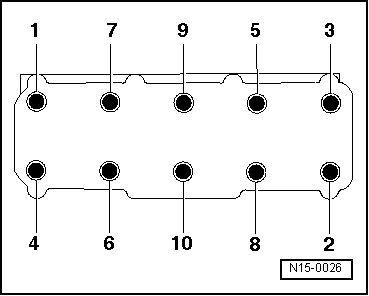

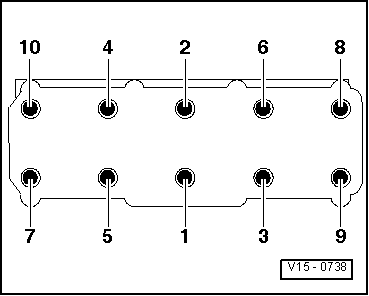

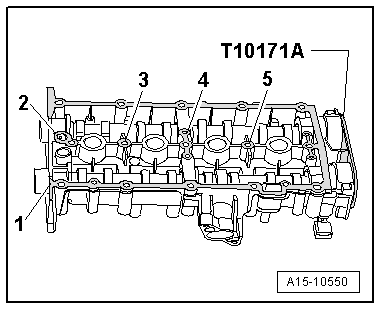

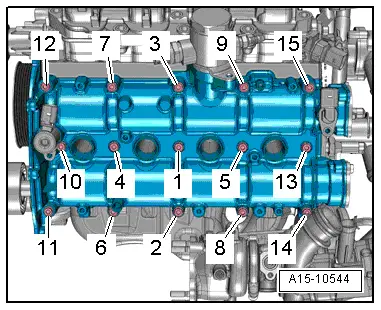

| Slacken cylinder head bolts in the sequence -1 ... 10-. |

| –

| Remove bolts and carefully take off cylinder head. |

| –

| Place cylinder head onto soft surface (foam plastic). |

Caution | Avoid damage to sealing surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

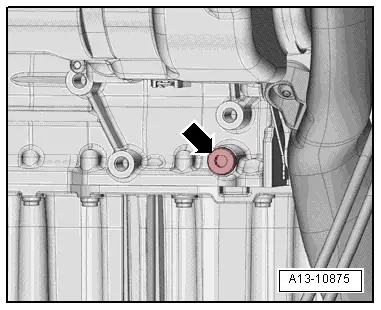

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Risk of leaks at cylinder head gasket. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

|

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| Renew self-locking nuts as well as seals, gaskets and O-rings. |

| t

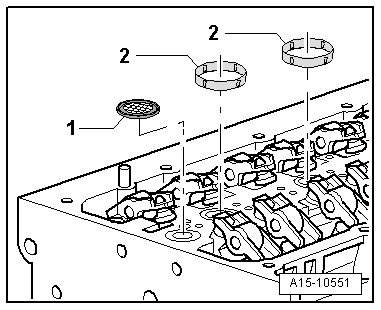

| Renew oil strainer in cylinder head. |

| t

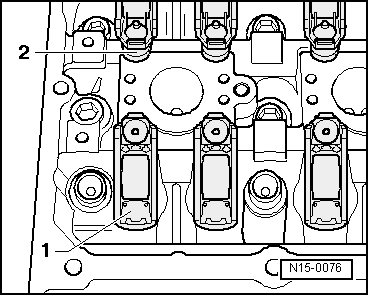

| When installing an exchange cylinder head, the contact surfaces between the hydraulic compensation elements, roller rocker fingers and cams must be oiled before installing the cylinder head cover. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and the coolant in the entire cooling system. |

Caution | Protect lubrication system and bearings against contamination. |

| Cover exposed parts of the engine. |

|

| –

| Remove sealant residue on cylinder head and camshaft housing. |

| –

| Clean surfaces; they must be free of oil and grease. |

| –

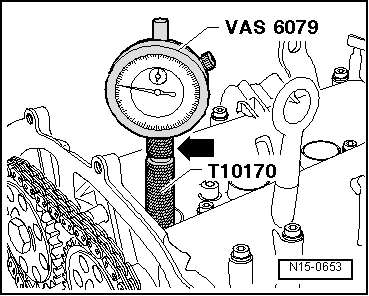

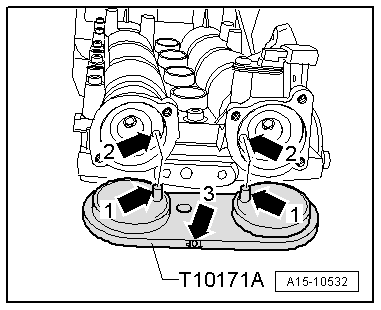

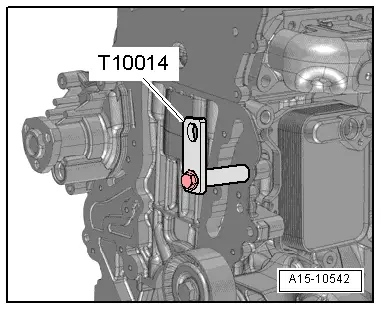

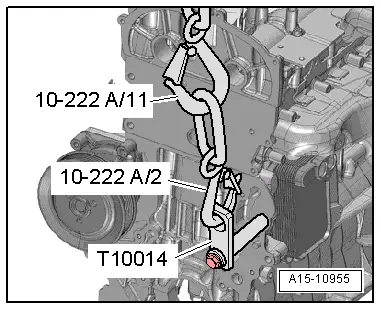

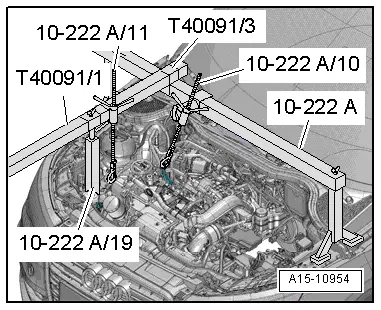

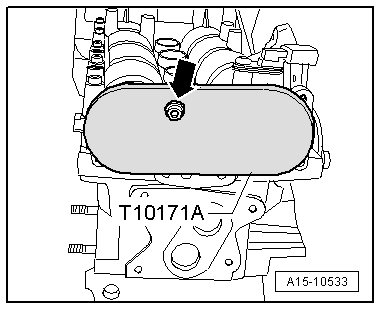

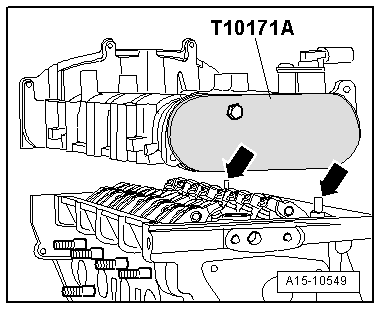

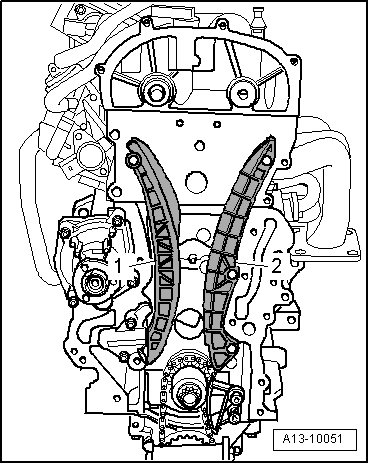

| Check that crankshaft is still positioned at „TDC“ and then turn back in the opposite direction of engine rotation by approx. 45°. |

| –

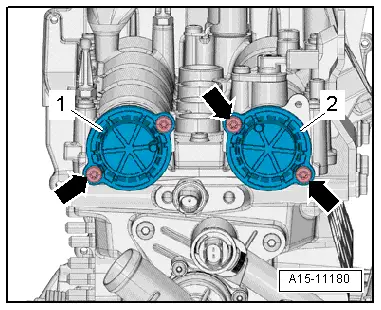

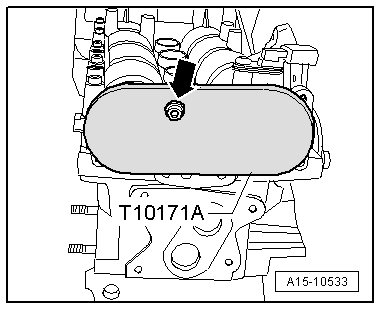

| Place cylinder head gasket in position. |

| l

| Installation position: Part No. must be visible. |

| l

| Note position of dowel sleeves in cylinder block. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution