Caution | Risk of damage to engine. |

| To prevent the crankshaft chain sprocket from slipping off the drive lug, do not rotate the crankshaft after the poly V-belt pulley has been detached. |

|

| –

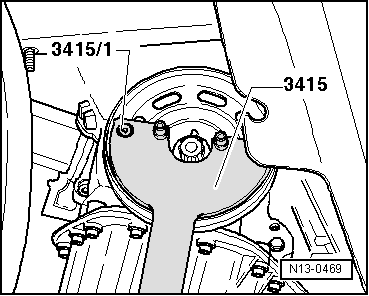

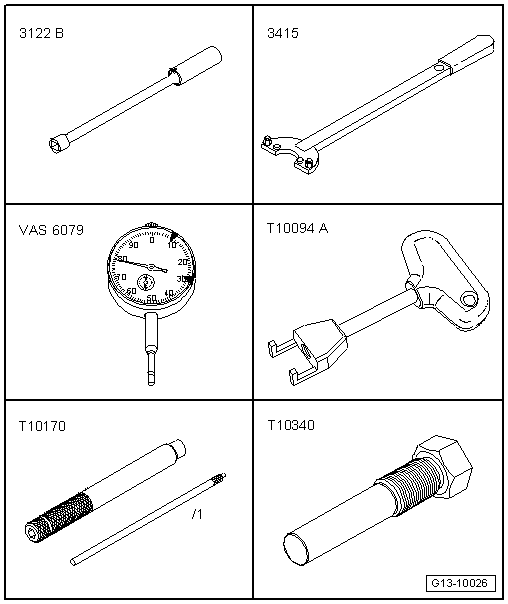

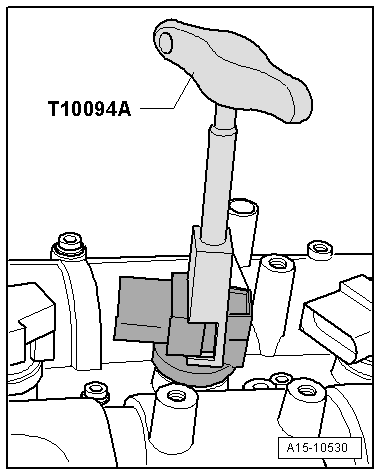

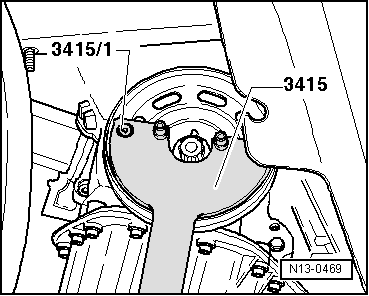

| Loosen bolt for poly V-belt pulley using counterhold tool -3415- with pin -3415/1-. |

| –

| Remove bolt and take off poly V-belt pulley. |

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| All contact surfaces between bolt, poly V-belt pulley, bearing bush and chain sprocket must be free of oil and grease. |

| –

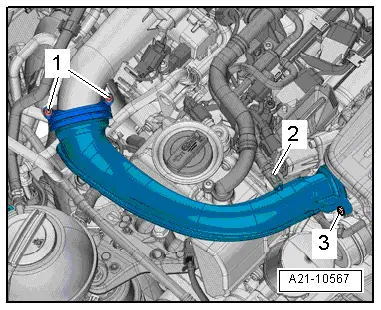

| Fit poly V-belt pulley, lubricate threads of bolt for poly V-belt pulley with oil and screw in by hand until bolt makes contact. |

Caution | Risk of damage to engine. |

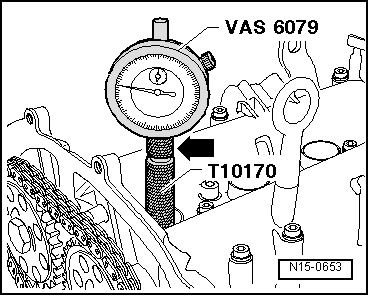

| t

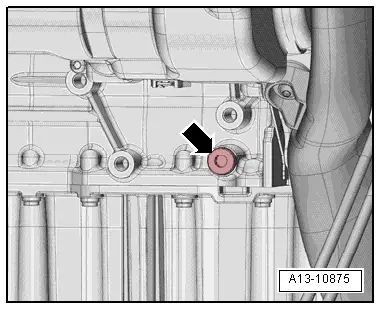

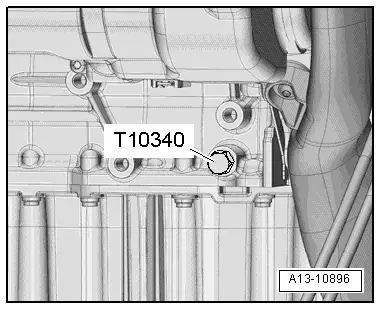

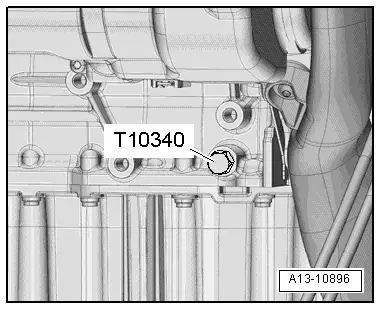

| Use dial gauge to check „TDC“ position of crankshaft. Crankshaft must only be brought into contact with locking pin -T10340- from „TDC“ position. |

| t

| Also use counterhold tool -3415- and pin -3415/1- to counterhold poly V-belt pulley when tightening bolt. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution