A1

|

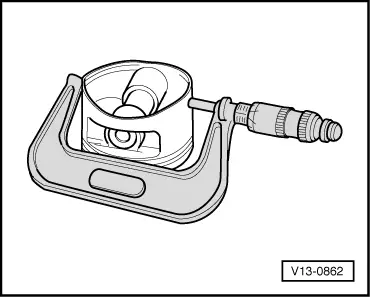

| Piston Ø | |||

| Nominal dimension | 80.96 mm 1) | ||

| |||

|

|

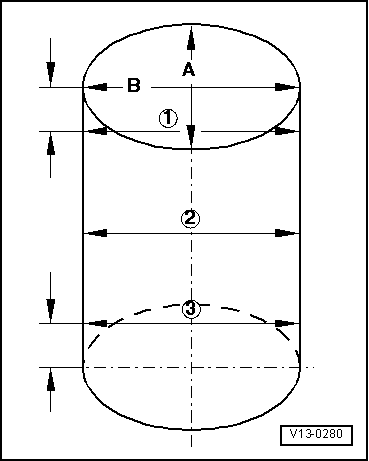

| Cylinder bore Ø | |

| Nominal dimension | 81.01 mm |

|

|

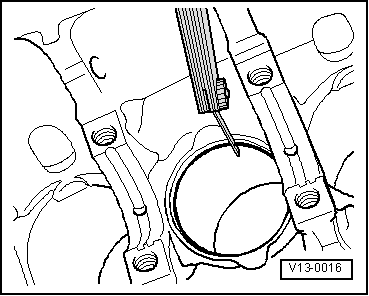

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.25 … 0.40 | 1.00 |

| 2nd compression ring | 0.25 … 0.40 | 1.00 |

| Oil scraper ring | 0.25 … 0.50 | 1.00 |

|

|

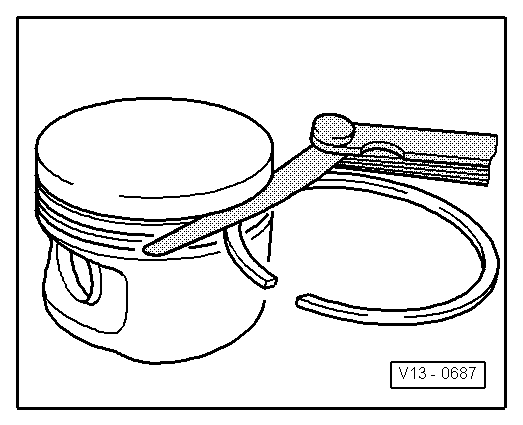

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.06 … 0.09 | 0.25 |

| 2nd compression ring | 0.05 … 0.08 | 0.25 |

| Oil scraper ring | 0.03 … 0.06 | 0.15 |

Note

Note