A1

| Pistons and conrods - exploded view |

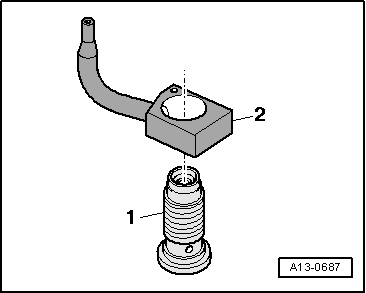

| 1 - | Bolt |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | 30 Nm + 90° further |

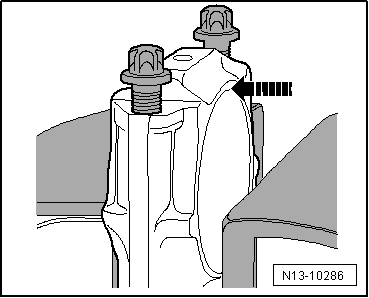

| 2 - | Conrod bearing cap |

| q | Due to the cracking method used to separate the bearing cap from the conrod in manufacture, the caps only fit in one position and only on the appropriate conrod |

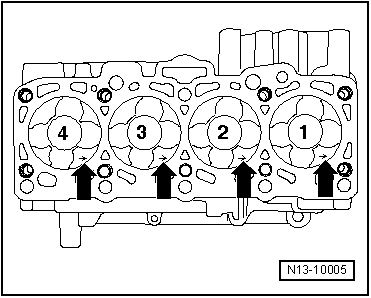

| q | Mark cylinder and conrod allocation in colour -B- |

| q | Installation position: Markings -A- face towards pulley end |

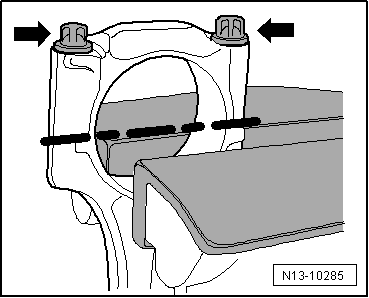

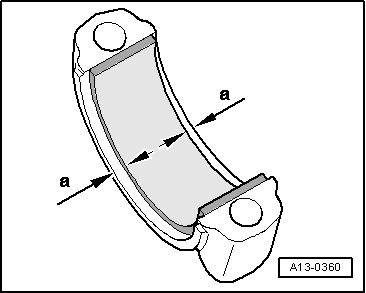

| 3 - | Bearing shell |

| q | Installation position → Fig. |

| q | Renew used bearing shells |

| q | Note version: Upper bearing shell (closest to piston) is constructed from a more wear-resistant material. Distinguishing feature on new bearing shells: black marking on bearing surface near joint |

| q | Check that it is securely seated |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | With industrially cracked conrod bearing cap |

| q | Separating parts of new conrod → Fig. |

| q | Mark cylinder and conrod bearing cap allocation in colour -B- |

| q | Installation position: Markings -A- face towards pulley end |

| q | Axial clearance: wear limit: 0.37 mm |

| q | Measuring radial clearance → Chapter |

| 5 - | Circlip |

| q | 2x |

| q | Renew |

| 6 - | Piston pin |

| q | Removing and installing → Chapter „Removing and installing pistons“ |

| 7 - | Piston |

| q | With combustion chamber |

| q | Version fitted in vehicle may differ from illustration |

| q | Mark installation position and cylinder number → Fig. |

| q | Removing and installing → Chapter |

| q | Measuring piston projection at „TDC“ → Chapter |

| q | Checking pistons and cylinder bores → Chapter |

| 8 - | Piston rings |

| q | Compression rings |

| q | Measuring ring gap → Fig. |

| q | Measuring ring-to-groove clearance → Fig. |

| q | Use piston ring pliers (commercially available) to remove and install |

| q | Installation position: marking „TOP“ or side with lettering faces towards piston crown |

| q | Offset gaps by 120° |

| 9 - | Piston ring |

| q | Oil scraper ring |

| q | Measuring ring gap → Fig. |

| q | Measuring ring-to-groove clearance → Fig. |

| q | Use piston ring pliers to remove and install |

| q | Installation position: marking „TOP“ or side with lettering faces towards piston crown |

| q | Offset gap 120° from bottom compression ring |

|

|

|

|

|

|

Note

Note

|

|