| –

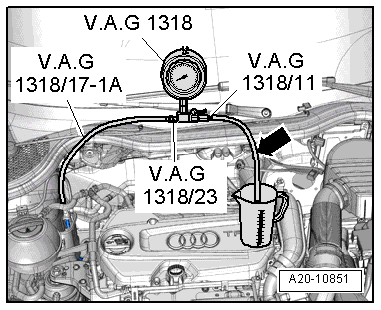

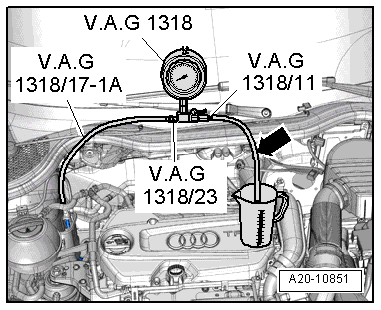

| Screw connector -V.A.G 1318/23- and adapter -V.A.G 1318/17-1A- onto K-Jetronic pressure tester -V.A.G 1318-. |

| –

| Fit -V.A.G 1318/17-1A- onto disconnected fuel line. |

| –

| Connect adapter -V.A.G 1318/11- to -V.A.G 1318-. |

| –

| Attach test hose -arrow- and hold end of hose in measuring container. |

Note | To measure the fuel delivery rate, pressure must first be built up in the fuel supply line; the fuel pump must then operate against this pressure during the measurement. This pressure can be built up using -V.A.G 1318- as follows: |

| –

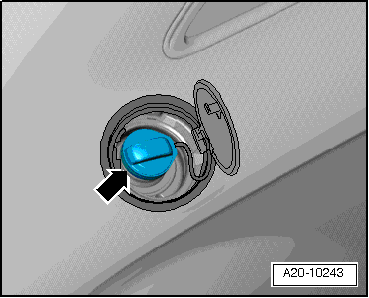

| Open cut-off valve on pressure tester. |

| l

| Lever must point in direction of flow. |

| –

| Connect vehicle diagnostic tester. |

| –

| Switch on the ignition and select the following menu options on the vehicle diagnostic tester: |

| t

| Checking fuel system pressurisation pump |

| –

| Press Start: The fuel pump will start running. |

| –

| Build up pressure in fuel system by slowly closing cut-off valve on pressure tester until correct pressure has been reached. |

| –

| From this point on do not move position of cut-off valve. |

| –

| Drain measuring container. |

| –

| For measurement, press Start again and let fuel pump run for 15 seconds. |

| –

| Press Stop after 15 seconds. |

| –

| Check amount of fuel delivered in measuring container. |

| l

| Specification for minimum delivery rate: at least 250 cm3 in 15 seconds (with a supply voltage of 12 V at the fuel pump). |

| If minimum delivery rate is not achieved, check for the following causes: |

| t

| Fuel lines have been crushed. |

| t

| Fuel filter is blocked. |

| t

| Fuel pump is defective. |

| Assemble in reverse order. |

|

|

|

Note

Note

Note

Note

WARNING

WARNING