| Ball hub and joint body are paired. Do not interchange. |

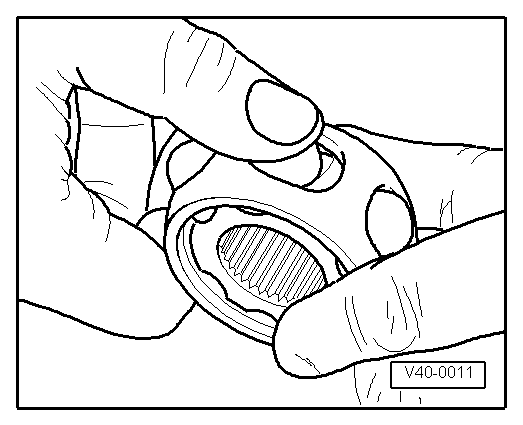

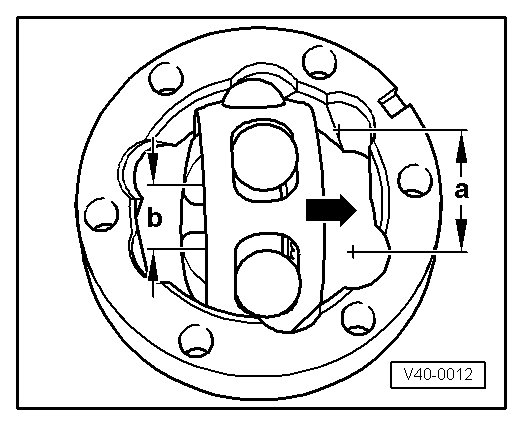

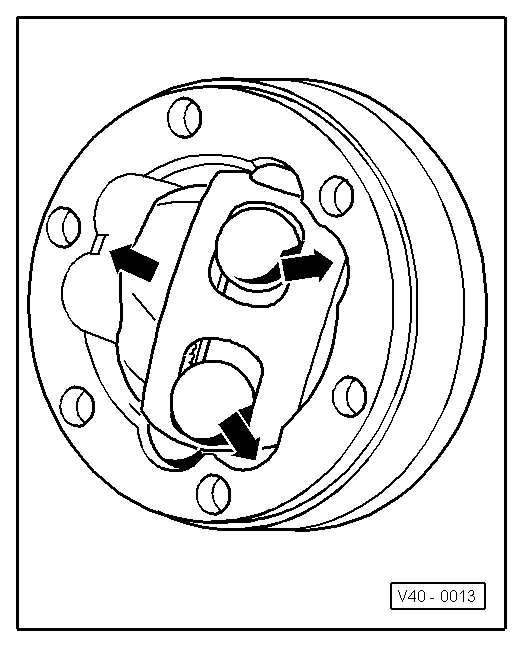

| –

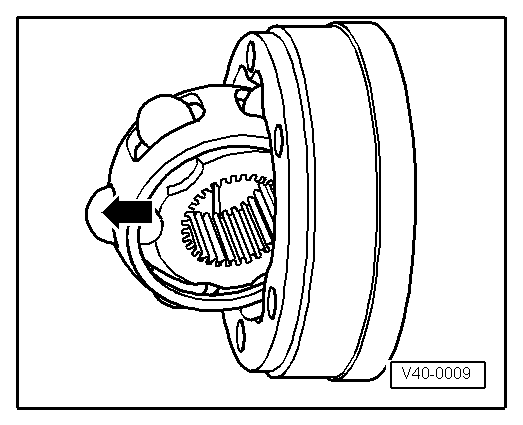

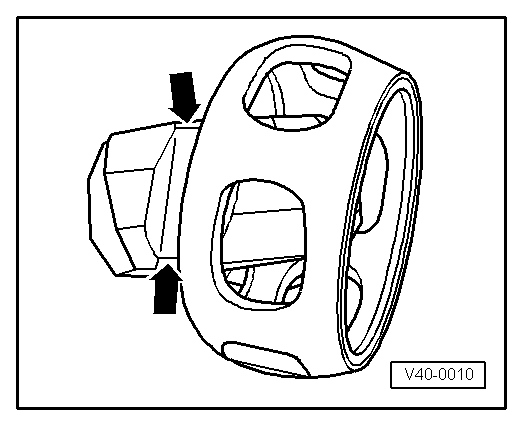

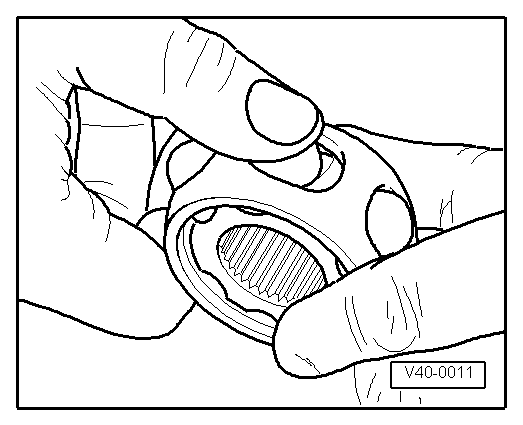

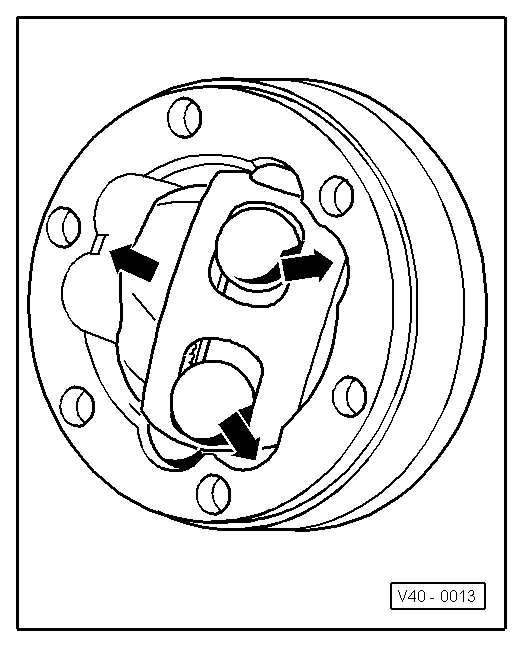

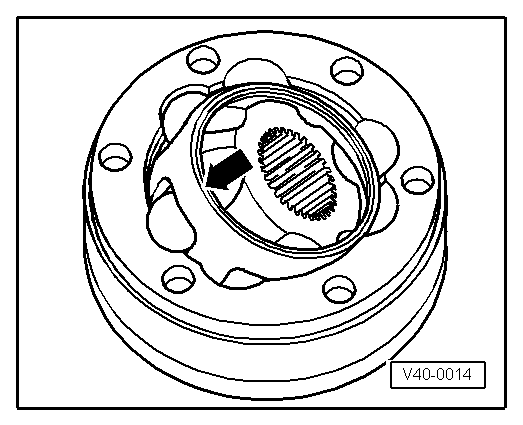

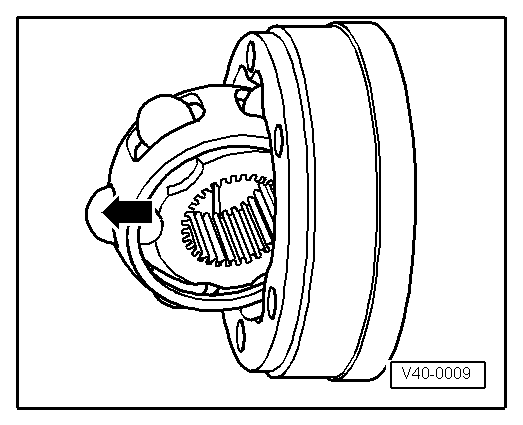

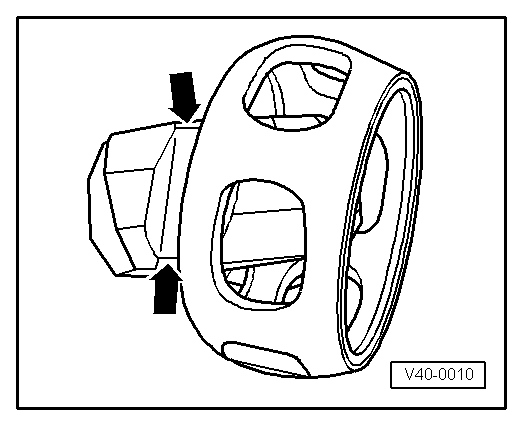

| Align ball hub with cage as shown -arrows- and pivot hub out of cage. |

| –

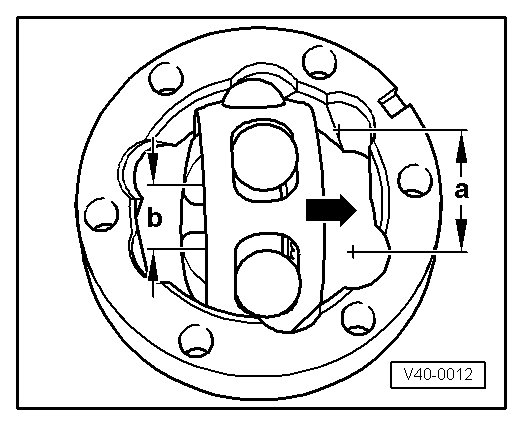

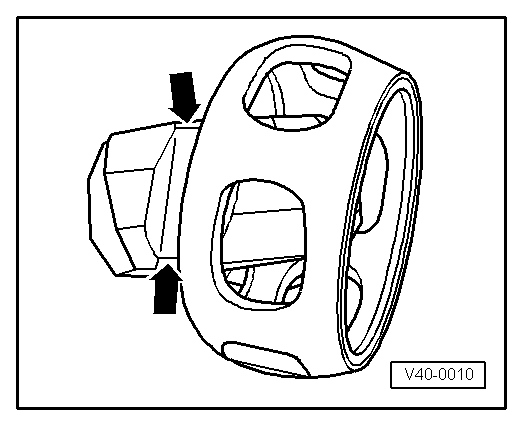

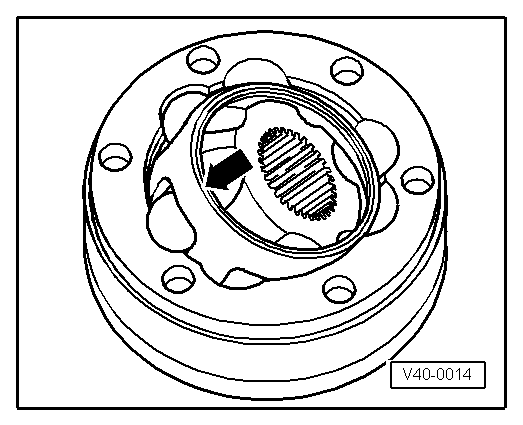

| Check joint, ball hub, ball cage and balls for pitting and signs of seizure. |

| Excessive backlash in the joint will cause knocking or jolts under load change. In such cases the joint must be renewed. Polished areas and visible tracks in the ball races are not a reason for renewing the joint. |

|

|

|