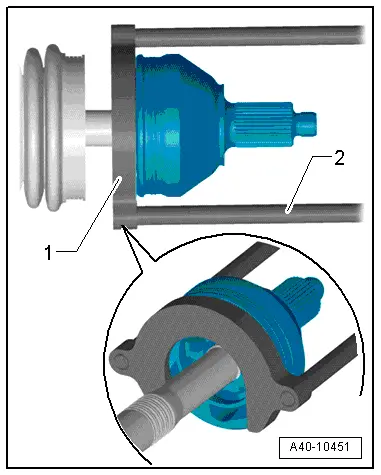

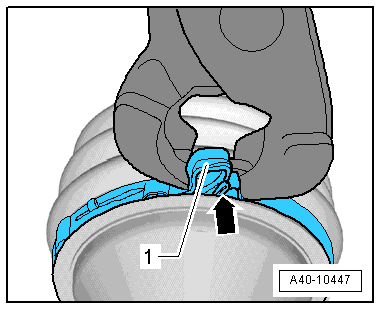

| Tightening hose clip on outer joint - version 2 |

| –

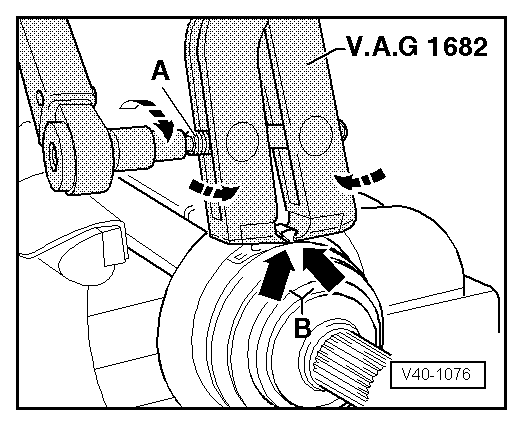

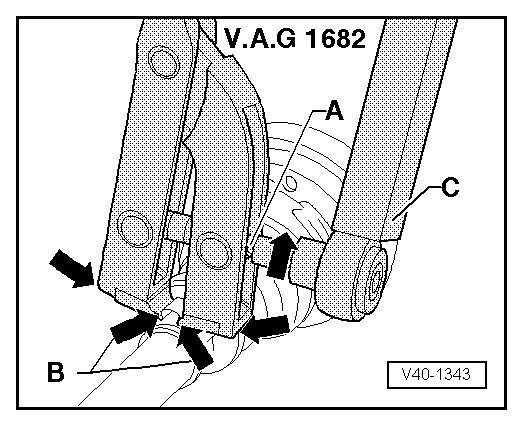

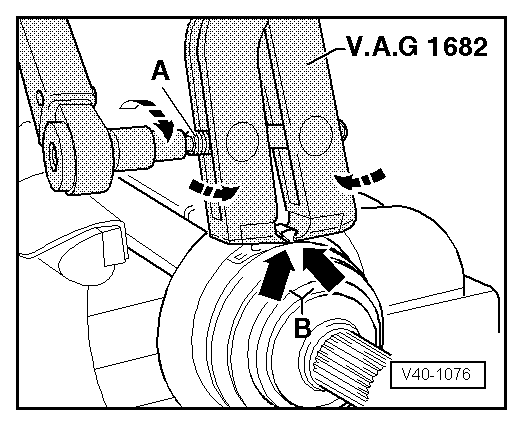

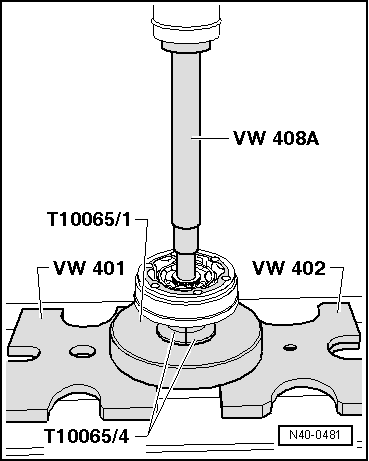

| Apply clamp tensioner -V.A.G 1682- as shown in illustration. Ensure jaws of tool make contact with lugs -arrows B- on hose clip. |

| –

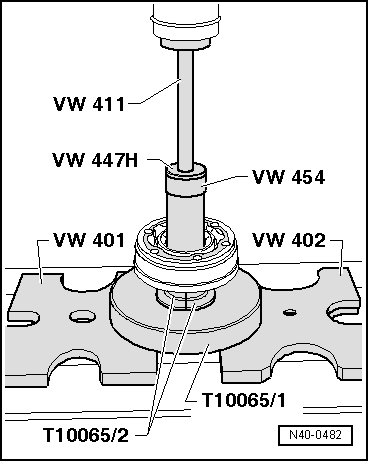

| Tighten hose clip by turning spindle with torque wrench (take care to keep tool straight). |

Note | t

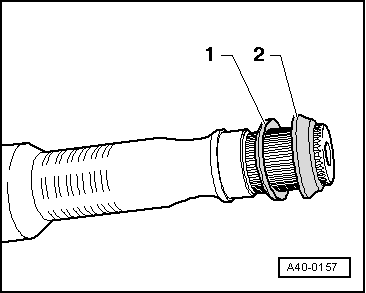

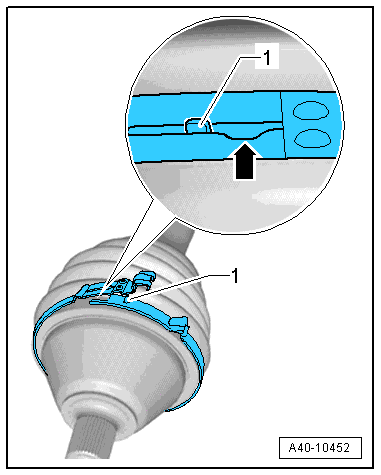

| Due to the hard material of the CV joint boot (as opposed to rubber), a stainless steel hose clip is required; this can only be tightened using clamp tensioner -V.A.G 1682-. |

| t

| Tightening torque: 25 Nm. |

| t

| Use torque wrench -C- with adjustment range 5 … 50 Nm (e.g. torque wrench -V.A.G 1331-). |

| t

| Make sure thread of spindle -A- on clamp tensioner turns freely. Lubricate with MOS2 grease if necessary. |

| t

| If the thread is stiff (e.g. due to dirt), the required clamping force will not be attained at the hose clip when the specified tightening torque is applied. |

|

|

|

Note

Note

Note

Note