| –

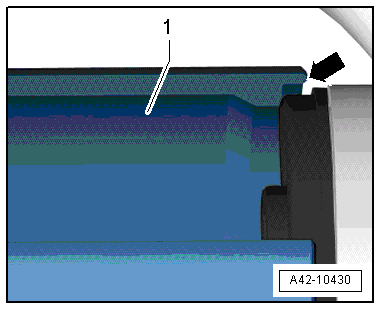

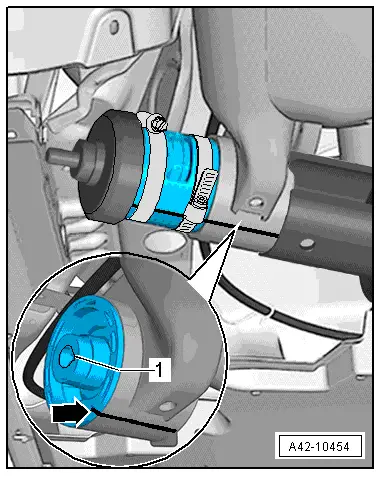

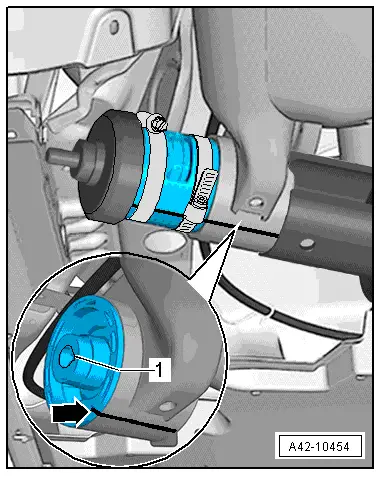

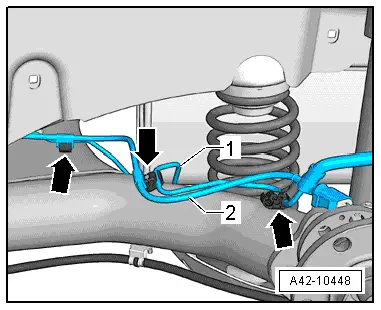

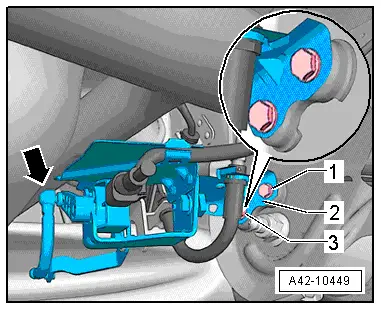

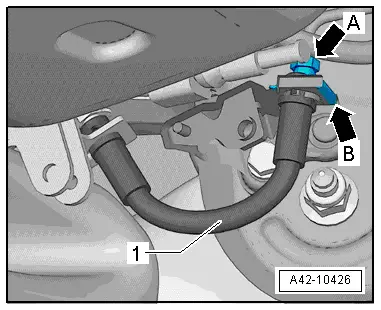

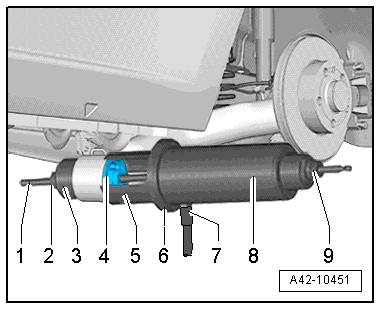

| Before pressing in bonded rubber bush, make sure groove -1- in inner core of bush faces towards rear of vehicle and bottom slit -arrow- in outer sleeve is in line with marking on axle beam. |

| –

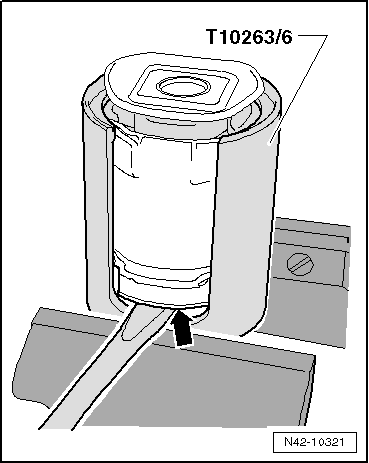

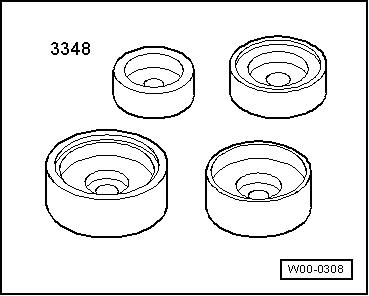

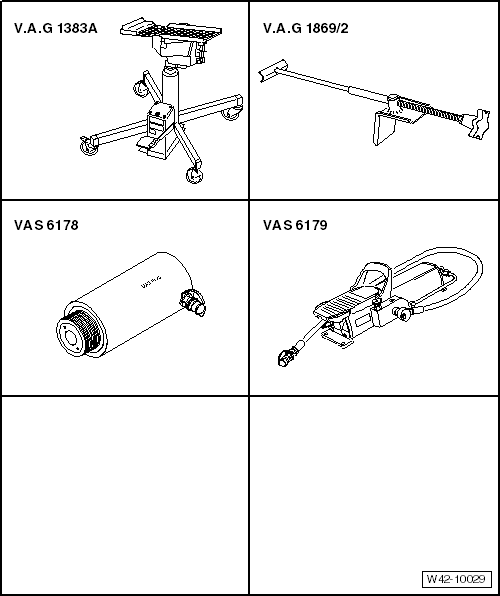

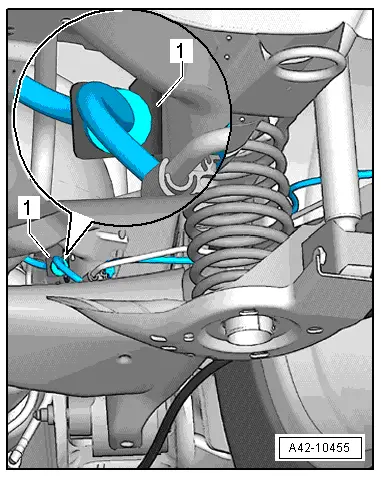

| Press in bonded rubber bush as far as first hose clip and then remove hose clip. |

| –

| Press in bonded rubber bush as far as second hose clip and then remove hose clip. |

| –

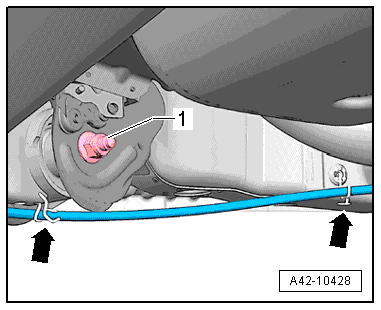

| Press in bonded rubber bush as far as stop. |

| –

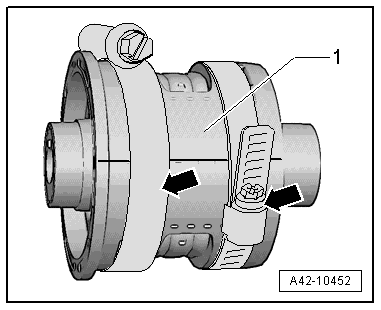

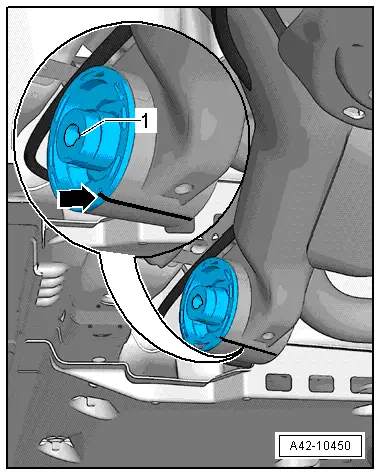

| After installation, check that bonded rubber bush is in correct position. |

| –

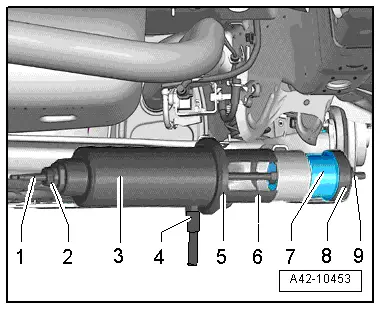

| Tighten rear axle mountings in unladen position → Chapter. |

| Remaining installation steps are carried out in reverse sequence. |

|

|

|

Note

Note

Note

Note