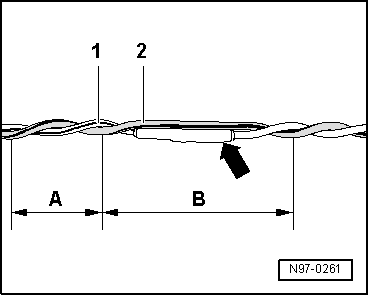

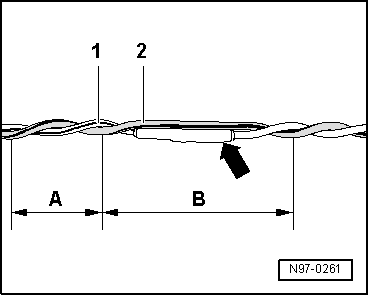

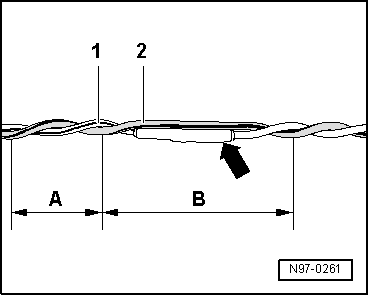

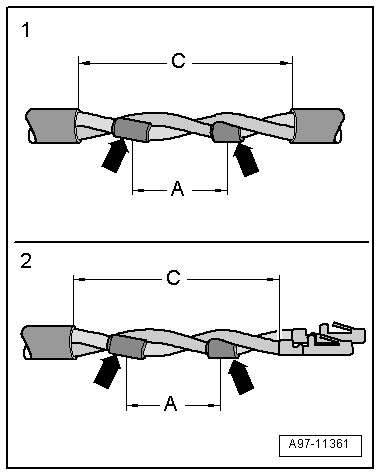

| FlexRay wiring consists of a sheathed pair of wires -1 and 2- with a cross-section of 0.35 mm2. |

| t

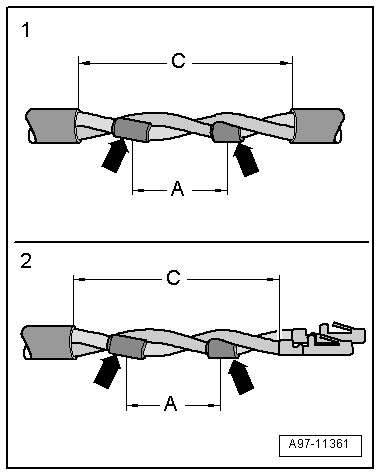

| Both wires must be of exactly the same length when repairing. |

| t

| When twisting the wires -1 and 2-, the twist length specification -A- = 30 mm must be met. |

| t

| When making repairs, there must be no untwisted section of wire which is longer than -B- = 50 mm, e.g. in the vicinity of crimp connectors -arrow-. |

|

|

|

Note

Note

Note

Note