A2

|

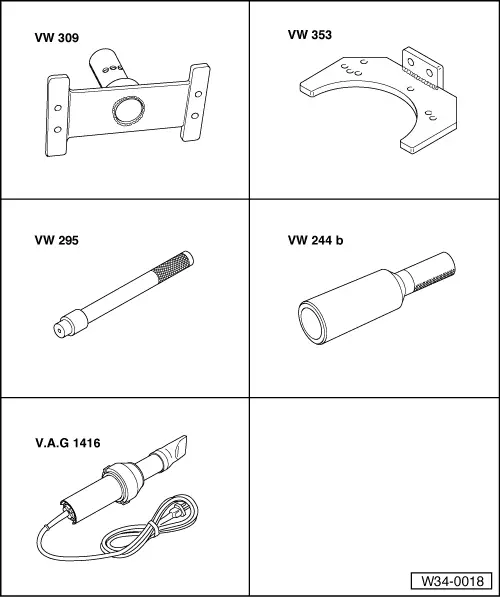

| Special tools and workshop equipment required |

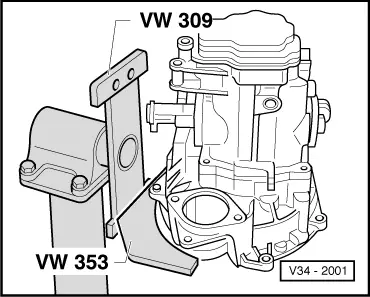

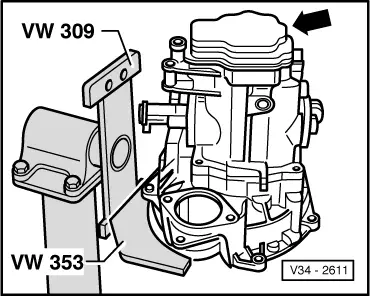

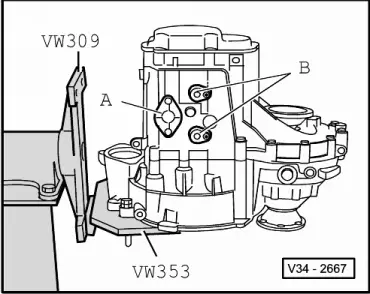

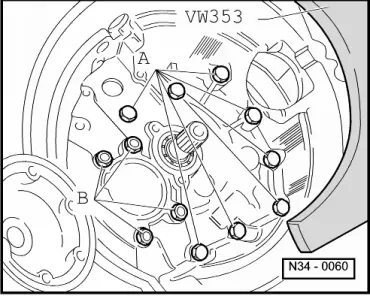

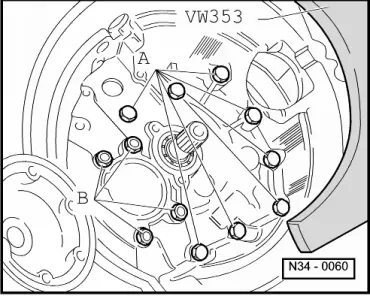

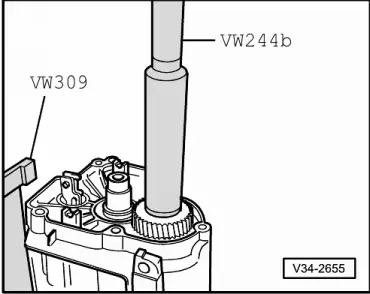

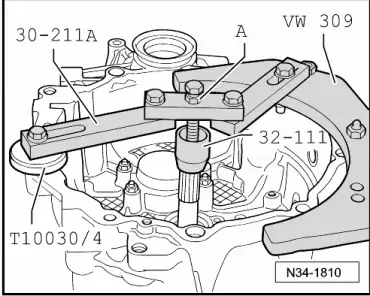

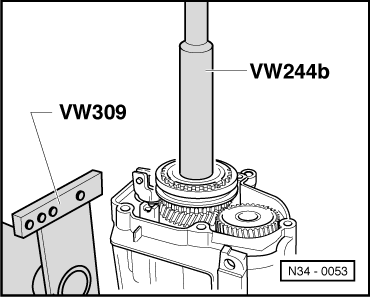

| t | Support plate -VW 309- |

| t | Gearbox support -VW 353- |

| t | Drift -VW 295- |

| t | Drift sleeve -VW 244 B- |

| t | Hot air blower -V.A.G 1416- |

| t | Sealing grease -G 052 128 A1- |

| t | Sealants -AMV 188 200 03- |

| t | Stud M8 x 100 mm |

| t | Bolt M10 x 20 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

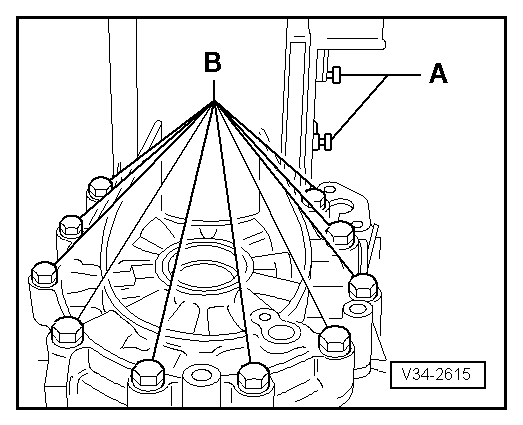

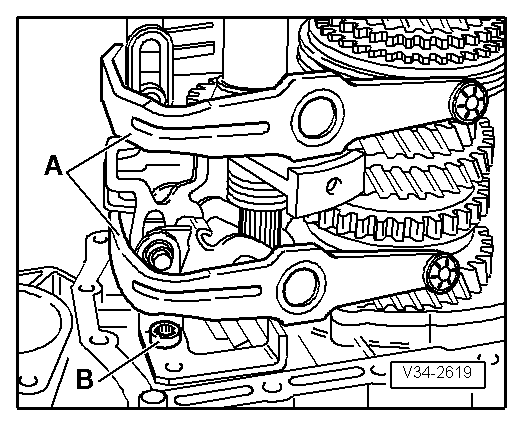

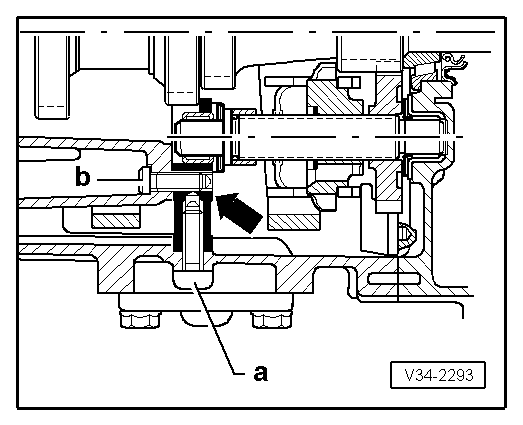

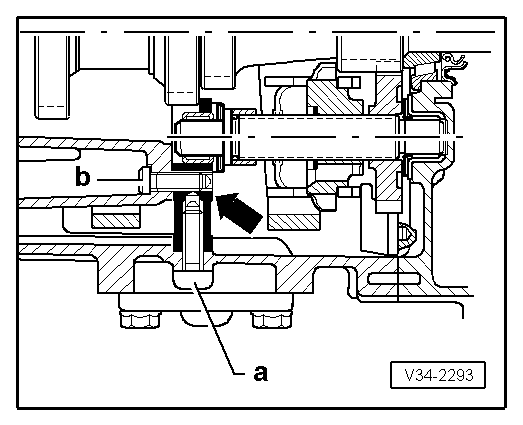

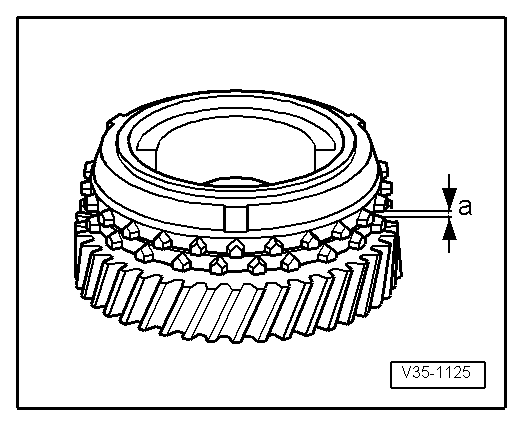

| Gap -a- | Specification | Wear limit |

| 5th gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|