A2

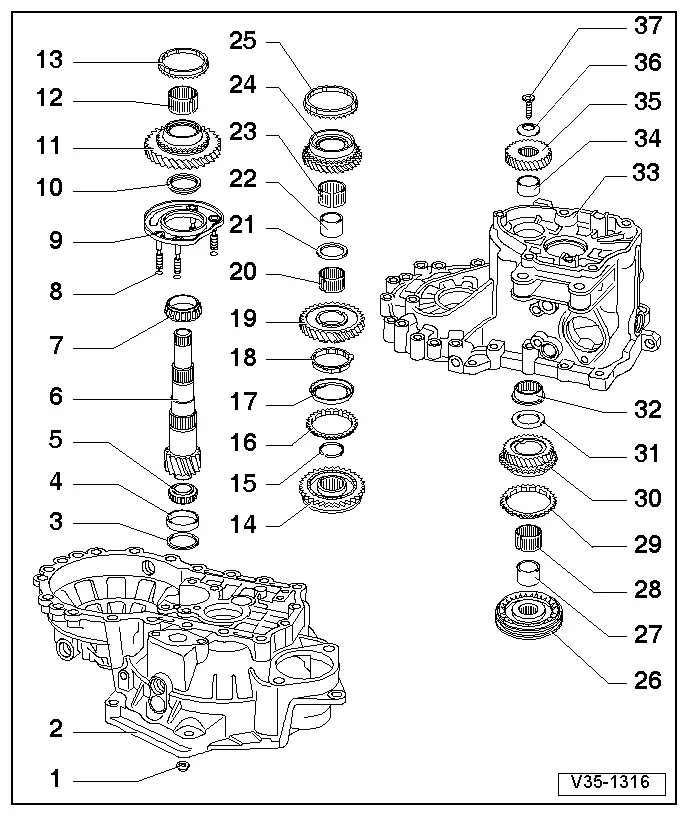

| Exploded view - dismantling and assembling output shaft |

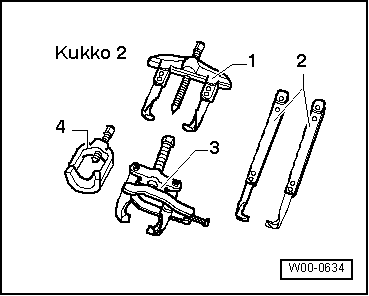

| Special tools and workshop equipment required |

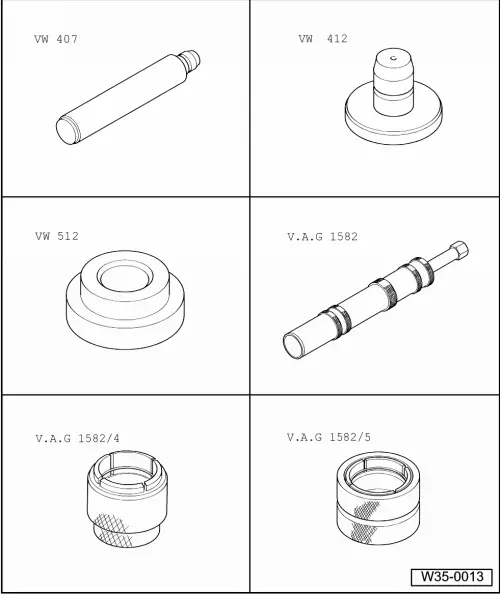

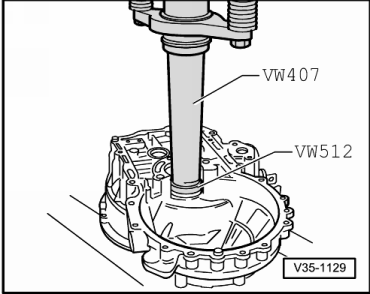

| t | Press tool -VW 407- |

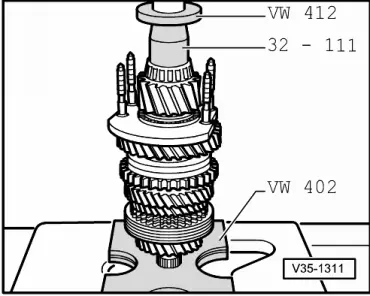

| t | Press tool -VW 412- |

| t | Thrust pad -VW 512- |

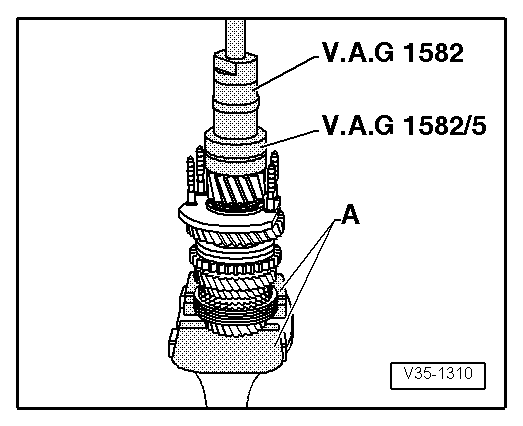

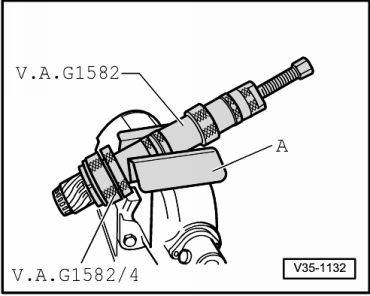

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/4- |

| t | Adapter -V.A.G 1582/5- |

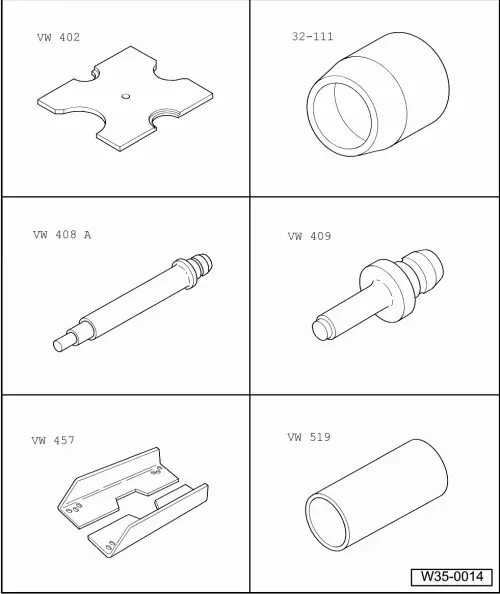

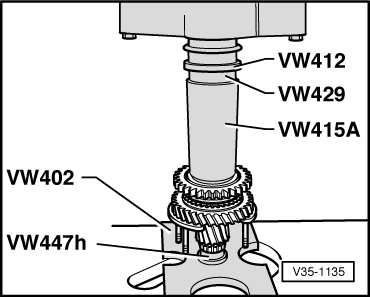

| t | Thrust plate -VW 402- |

| t | Thrust piece -32 - 111- |

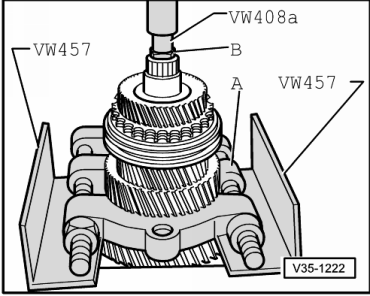

| t | Press tool -VW 408 A- |

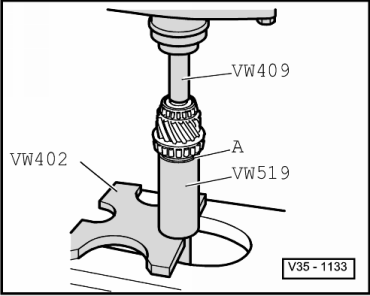

| t | Press tool -VW 409- |

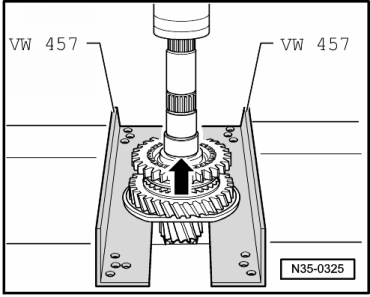

| t | Support rails -VW 457- |

| t | Tube -VW 519- |

| t | Thrust ring -VW 429- |

| t | Tube -VW 415 A- |

| t | Thrust plate -VW 447 H- |

| t | Press tool -VW 454- |

| t | Installing sleeve -VW 455- |

| t | Drift sleeve -41 - 501- |

|

|

|

|

|

|

Note

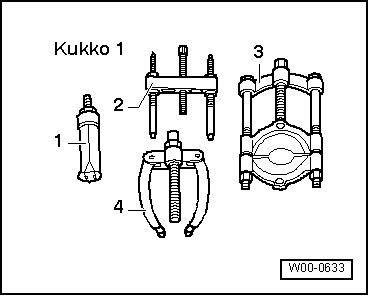

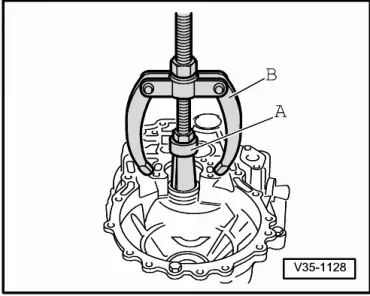

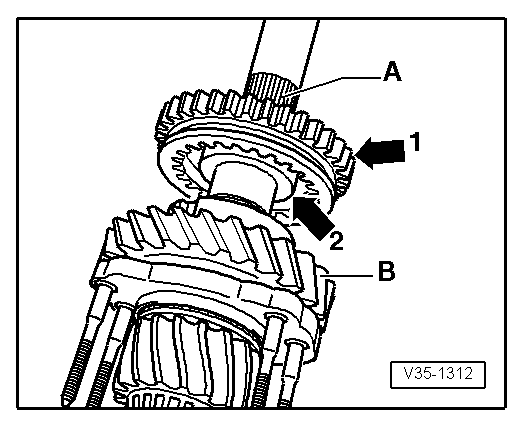

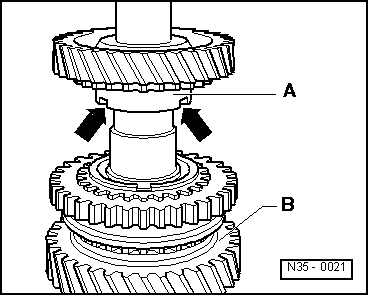

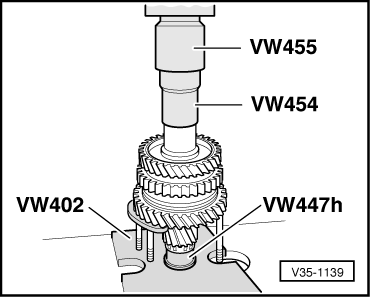

Note| t | The output shaft is dismantled as follows: - Position splitter under 2nd speed selector gear ( → Item) and press off as described in → Fig.. - Remove circlip → Item. Fit two-arm puller under bearing mounting ( → Item) and pull off 1st and 2nd gear locking collar and synchronising hub as shown in → Fig. |

| t | Refer to technical data → Chapter when installing new gears or a new output shaft. |

| t | Always renew both tapered roller bearings together. |

| t | Do not over-stretch circlip → Item. Always renew circlips which have been damaged or over-stretched. |

| 1 - | Hexagon nut |

| q | 25 Nm and turn 90° further |

| q | 4 nuts for bearing mounting |

| 2 - | Clutch housing |

| 3 - | Shim |

| q | For output shaft |

| q | Determining thickness - Adjusting output shaft → Chapter |

| q | Table of adjustments → Chapter |

| 4 - | Small tapered roller bearing outer race |

| q | Removing → Fig. |

| q | Pressing in → Fig. |

| 5 - | Small tapered roller bearing inner race |

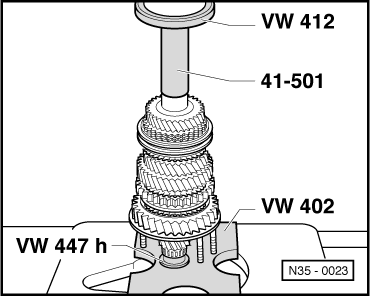

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 6 - | Output shaft |

| q | Is paired with final drive gear, only renew as a set |

| q | Adjusting → Chapter |

| 7 - | Large tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 8 - | O-ring |

| q | Place O-rings (4x) on bolts for bearing mounting |

| 9 - | Bearing mounting |

| q | With large tapered roller bearing outer race and bolts |

| q | Only renew outer race together with large tapered roller bearing and bearing mounting |

| 10 - | Thrust washer |

| q | Shoulder on thrust washer faces towards large tapered roller bearing inner race → Item |

| 11 - | 1st speed selector gear |

| q | Modified 1st gear synchromesh from gearbox build date 02 05 0 → Chapter |

| 12 - | Needle bearing |

| q | For 1st gear |

| 13 - | 1st gear synchro-ring |

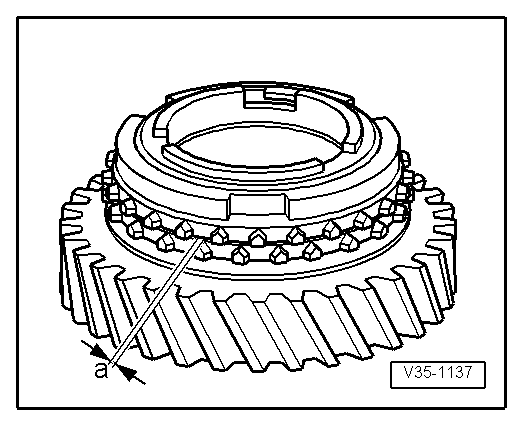

| q | Checking for wear → Fig. |

| q | Identification → Fig. |

| q | Distinguishing 1st and 2nd gear synchro-rings → Fig. |

| q | Modified 1st gear synchromesh from gearbox build date 02 05 0 → Chapter |

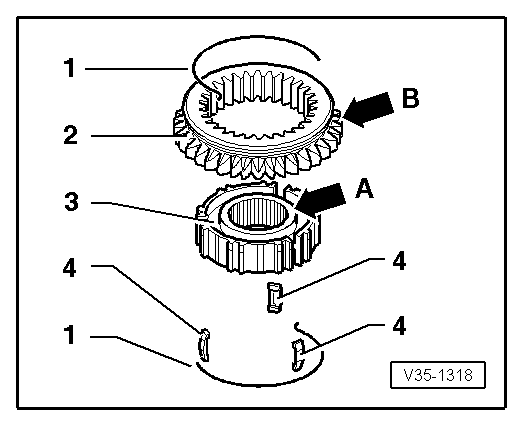

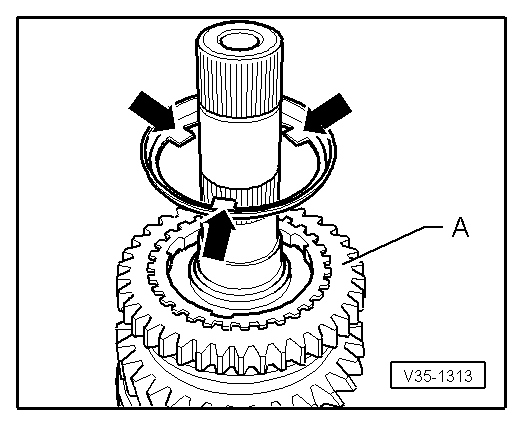

| 14 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Press off together with bearing mounting → Item after removing circlip → Fig. |

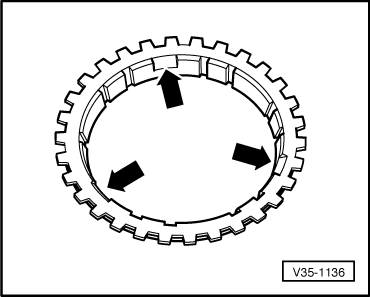

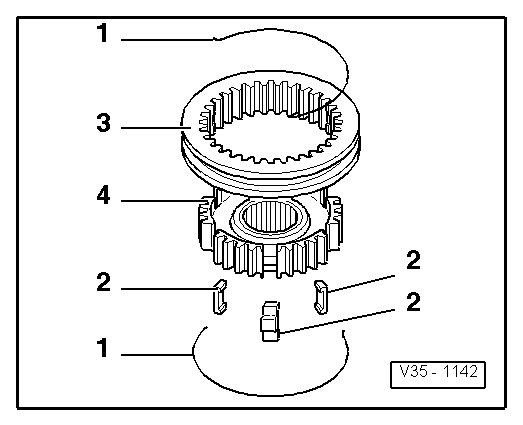

| q | Dismantling → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Installation position → Fig. |

| q | Pressing on → Fig. |

| q | Modified 1st gear synchromesh from gearbox build date 02 05 0 → Chapter |

| 15 - | Circlip |

| 16 - | 2nd gear synchro-ring |

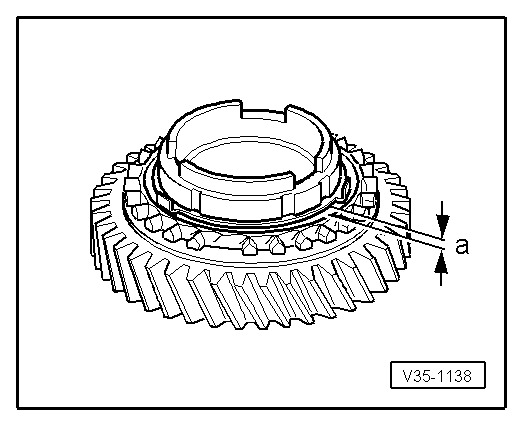

| q | Checking for wear → Fig. |

| q | Identification → Fig. |

| q | Distinguishing 1st and 2nd gear synchro-rings → Fig. |

| q | Assemble so that the recesses engage on the locking pieces on the locking collar ( → Item) |

| 17 - | Outer ring |

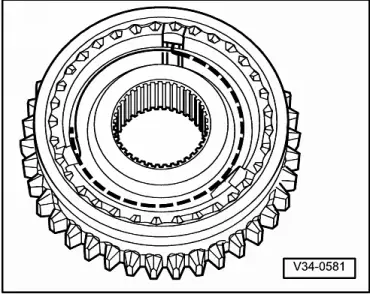

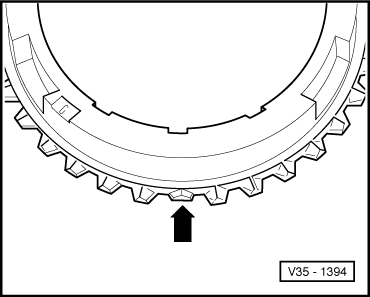

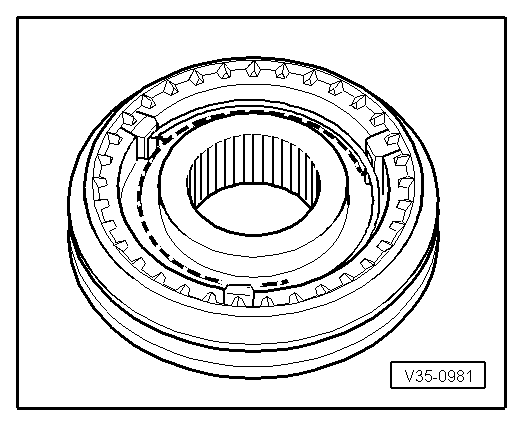

| q | Insert in synchro-ring ( → Item); installation position → Fig. |

| q | Renew if scored or if there are visible traces of wear |

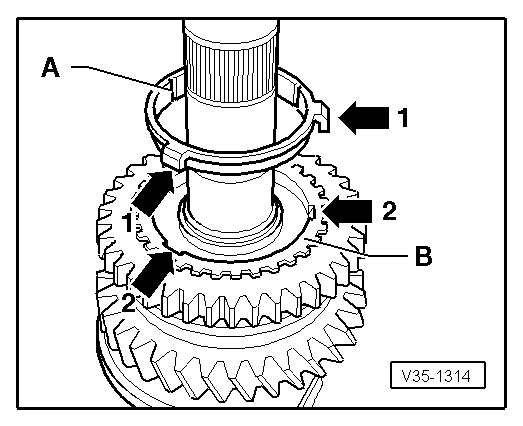

| 18 - | Synchro-ring |

| q | Inner ring |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 19 - | 2nd speed selector gear |

| q | Installation position → Fig. |

| 20 - | Needle bearing |

| q | For 2nd gear |

| 21 - | Thrust washer |

| 22 - | Sleeve for 3rd gear needle bearing |

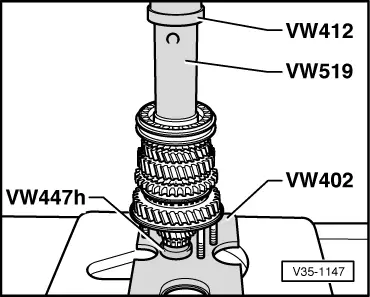

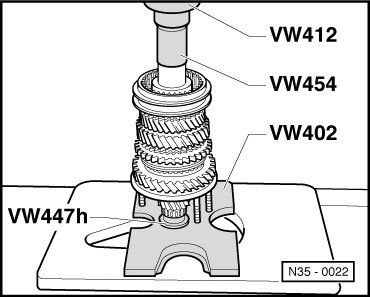

| q | Pressing off with 2nd speed selector gear → Fig. |

| q | Pressing on → Fig. |

| 23 - | Needle bearing |

| q | For 3rd gear |

| 24 - | 3rd speed selector gear |

| 25 - | 3rd gear synchro-ring |

| q | Checking for wear → Fig. |

| 26 - | Locking collar with synchronising hub for 3rd and 4th gear |

| q | Pressing off with 2nd speed selector gear ( → Item) and 3rd speed selector gear ( → Item) → Fig. |

| q | Dismantling → Fig. |

| q | Installation position: Locking collar/synchronising hub → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 27 - | Sleeve |

| q | For 4th gear needle bearing |

| q | Pressing off with locking collar and synchronising hub for 3rd and 4th gear ( → Item) → Fig. |

| q | Pressing on → Fig. |

| 28 - | Needle bearing |

| q | For 4th gear |

| 29 - | 4th gear synchro-ring |

| q | Checking for wear → Fig. |

| 30 - | 4th speed selector gear |

| 31 - | Thrust washer |

| 32 - | Needle bearing |

| q | For output shaft |

| q | Removing and installing → Fig. |

| 33 - | Gearbox housing |

| 34 - | Sleeve |

| q | For needle bearing → Item |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 35 - | 5th gear wheel |

| q | Removing and installing → Chapter |

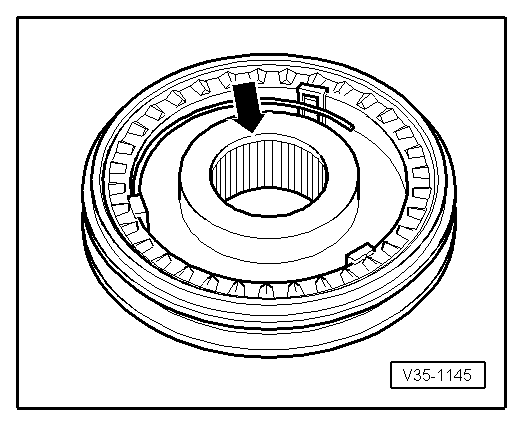

| 36 - | Dished spring |

| q | Installation position → |

| 37 - | Bolt |

| q | M10 x 1 |

| q | Tightening torque → Item |

| q | Always renew |

| q | Fitted piece on bolt head holds dished spring in position |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

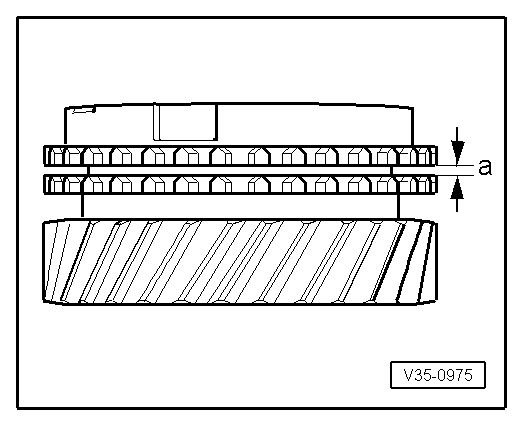

| Gap -a- | Specification | Wear limit | ||

| 1st gear1) 3rd gear 4th gear | 1.0…1.7 mm 1.0…1.7 mm 1.0…1.7 mm | 0.5 mm | ||

| ||||

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

| Gap -a- | Specification | Wear limit |

| 2nd gear | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

| Gap -a- | Specification | Wear limit |

| 2nd gear | 0.75 ... 1.25 mm | 0.3 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|