A2

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

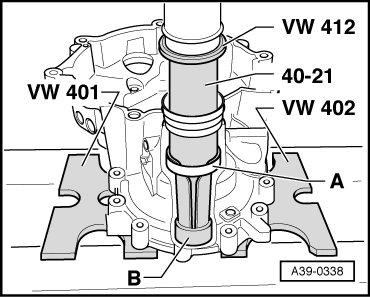

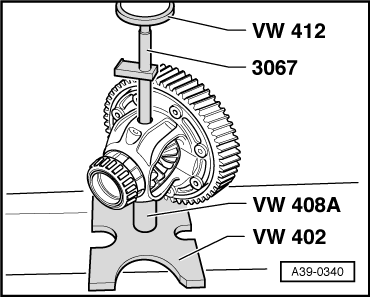

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

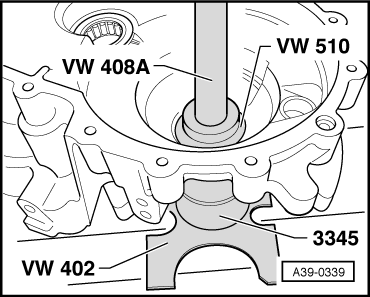

| t | Press tool -VW 408 A- |

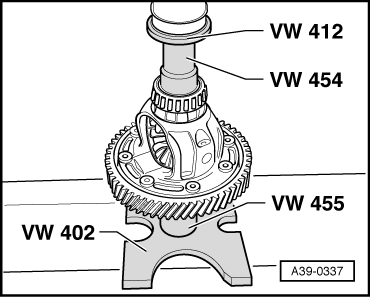

| t | Press tool -VW 412- |

| t | Tube -VW 418 A- |

| t | Press tool -VW 454- |

| t | Installing sleeve -VW 455- |

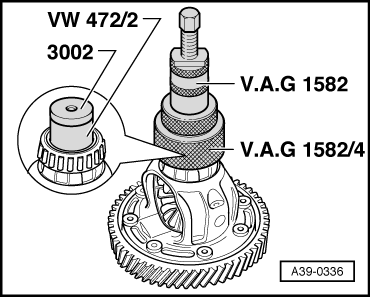

| t | Spacer sleeve -VW 472/2- |

| t | Thrust pad -VW 510- |

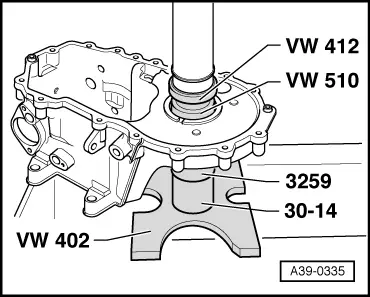

| t | Tube -30 - 14- |

| t | Press tool -40 - 21- |

| t | Thrust piece -3002- |

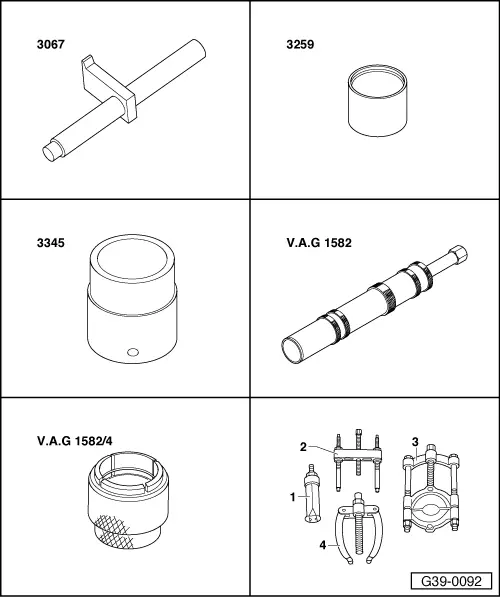

| t | Counterhold tool -3067- |

| t | Tube -3259- |

| t | Wheel bearing tube -3345- |

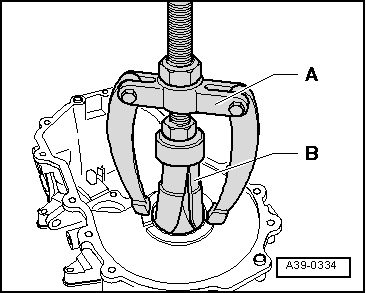

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/4- |

| t | -1-Internal puller 46...58 mm, e.g. -Kukko 21/7- |

| t | -4-Counter support, e.g. -Kukko 22/2- |

Note

Note| t | Heat tapered roller bearing inner race to 100° C before installing. |

| t | Always renew both tapered roller bearings together. |

| t | Items 14, 15/16, 17 and 23 were modified from gearbox build date 06 05 2 → Chapter. Select correct components from → Electronic parts catalogue. |

| t | Adjust differential if tapered roller bearings, differential cage, gearbox housing or clutch housing are renewed → Chapter. |

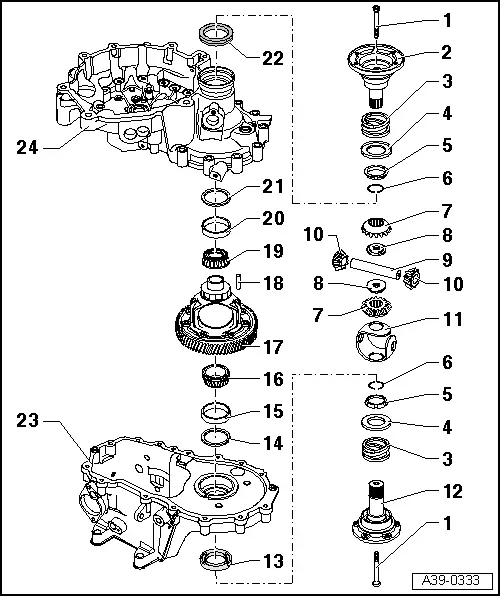

| 1 - | Countersunk bolt |

| q | 25 Nm |

| q | Screws into threaded piece → Item |

| 2 - | Flange shaft (right-side) |

| q | Do not interchange; left and right flange shafts are different |

| 3 - | Spring for flange shaft |

| q | Installed behind flange shafts |

| 4 - | Thrust washer |

| q | Installation position: lip faces spring |

| 5 - | Tapered ring |

| q | Installation position: Taper towards differential cage |

| 6 - | Circlip |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft is removed |

| 7 - | Sun wheel |

| q | Installing → Fig. |

| 8 - | Threaded piece |

| q | Installing → Fig. |

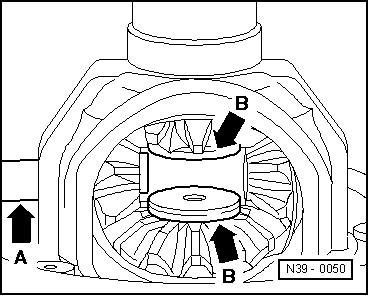

| 9 - | Differential pinion pin |

| q | To remove, shear off spring pin → Item → Fig. |

| q | Installing → Fig. |

| 10 - | Planet pinion |

| q | Installing → Fig. |

| 11 - | One-piece thrust washer |

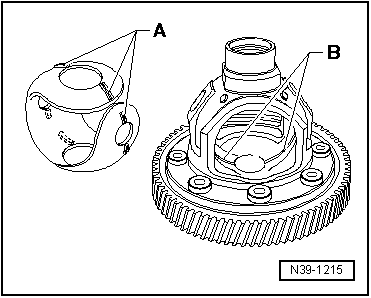

| q | Modified on some gearbox versions → Fig. |

| q | Lubricate with gear oil before installing |

| q | For correct version, refer to → Electronic parts catalogue |

| 12 - | Flange shaft (left-side) |

| q | With dust plate |

| q | Do not interchange; left and right flange shafts are different |

| 13 - | Flange shaft oil seal (left-side) |

| q | Different diameters for left and right |

| q | Renewing with gearbox installed → Chapter |

| 14 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thick |

| q | Modification: adapted to enlarged tapered roller bearing on gearbox housing side → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 15 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Modification: enlarged from gearbox build date 06 05 2 → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 16 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| q | Modification: enlarged from gearbox build date 06 05 2 → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 17 - | Differential cage |

| q | With final drive gear |

| q | Modification: adapted to enlarged tapered roller bearing on gearbox housing side → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 18 - | Spring pin |

| q | For securing differential pinion pin |

| q | Is sheared off on removal → Fig. |

| q | Installing → Fig. |

| 19 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 20 - | Tapered roller bearing outer race |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 21 - | Shim S2 |

| q | For differential |

| q | Determining thickness → Chapter |

| 22 - | Oil seal |

| q | For flange shaft (right-side) |

| q | Different diameters for left and right |

| q | Renewing with gearbox installed → Chapter |

| 23 - | Gearbox housing |

| q | Modification from gearbox build date 06 05 2: enlarged bearing seat for tapered roller bearing/differential → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 24 - | Clutch housing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|