A2

Note

Note

|

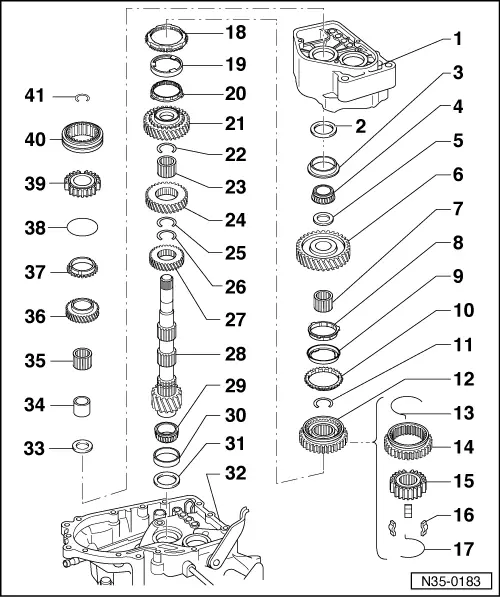

| 1 - | Gearbox housing |

| 2 - | Washer |

| q | 1 mm thick |

| 3 - | Tapered roller bearing outer race |

| q | Press out of gearbox housing with output shaft |

| q | Pressing in → Fig. |

| 4 - | Tapered roller bearing inner race |

| q | Press off with 1st speed selector gear → Fig. |

| q | Pressing on → Fig. |

| 5 - | Thrust washer |

| 6 - | 1st speed selector gear |

| q | Installation position → Fig. |

| 7 - | Needle bearing |

| q | For 1st gear |

| 8 - | Synchro-ring (inner ring for 1st gear) |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 9 - | Outer ring for 1st gear |

| q | Insert in synchro-ring -Item 10- |

| q | Installation position → Fig. |

| q | Renew if scored |

| 10 - | 1st gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Insert such that recesses engage in locking pieces of locking collar -Item 12- |

| 11 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 12 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Parts are paired |

| q | Pressing off → Fig. |

| q | Assembling locking collar and synchro-hub → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 13 - | Spring |

| 14 - | Locking collar |

| 15 - | Synchronising hub |

| 16 - | Locking piece |

| q | 3x |

| 17 - | Spring |

| 18 - | 2nd gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Installation position → Fig. |

| 19 - | Outer ring for 2nd gear |

| q | Position on synchro-ring -Item 20- |

| q | Installation position → Fig. |

| q | Renew if scored |

| 20 - | Synchro-ring (inner ring for 2nd gear) |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 21 - | 2nd speed selector gear |

| 22 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 23 - | Needle bearing |

| q | For 2nd gear |

| 24 - | 3rd gear wheel |

| 25 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 26 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 27 - | 4th gear wheel |

| q | Identification groove points towards final drive splines |

| 28 - | Output shaft |

| q | Dismantling and assembling → Chapter |

| q | Pay attention to correct ratio (number of teeth) → Chapter |

| q | Adjusting → Chapter |

| 29 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 30 - | Tapered roller bearing outer race |

| q | Removing → Fig. |

| q | Pressing in → Fig. |

| 31 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Chapter |

| 32 - | Clutch housing |

| 33 - | Thrust washer |

| q | Shoulder on thrust washer faces towards tapered roller bearing |

| 34 - | Sleeve for needle bearing |

| q | Press off with 1st speed selector gear → Fig. |

| q | Driving on → Anchor |

| 35 - | Needle bearing |

| q | For 5th speed selector gear |

| 36 - | 5th speed selector gear |

| 37 - | 5th gear synchro-ring |

| 38 - | Spring |

| q | Position on 5th gear synchro-ring |

| q | Renew if worn |

| 39 - | 5th gear synchronising hub |

| q | Removing → Chapter |

| 40 - | 5th gear locking collar |

| q | Removing → Chapter |

| 41 - | Circlip |

| q | Renew |

| q | Determining thickness |