A2

| Removing engine |

| Special tools and workshop equipment required |

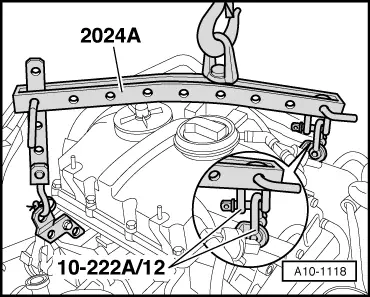

| t | Shackle -10-222 A/12- |

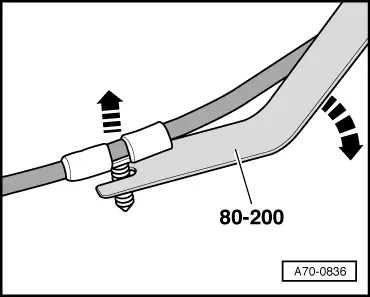

| t | Removal lever -80-200- |

| t | Lifting tackle -2024 A- |

| t | Ball joint puller -3287 A- |

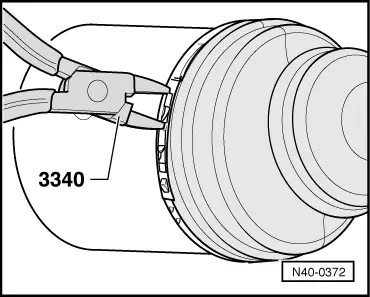

| t | Pliers -3340- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Workshop hoist -VAS 6100- |

| t | Drip tray for workshop hoist -VAS 6208- |

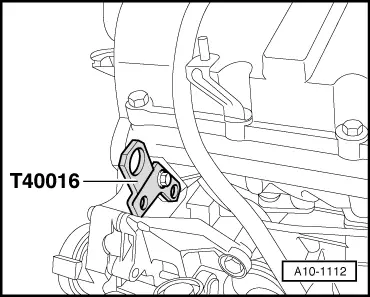

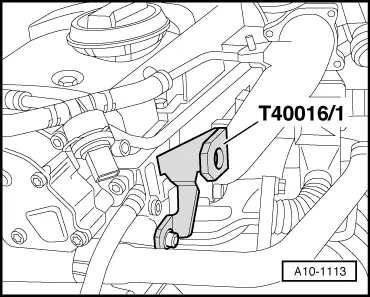

| t | Transportation shackle -T40016- with -T40016/1- |

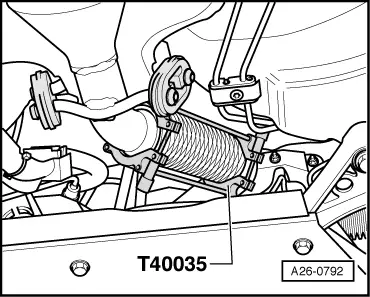

| t | Setting tool -T40035- |

Note

Note

Note

Note |

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING