A2

| Pistons and conrods - exploded view of components |

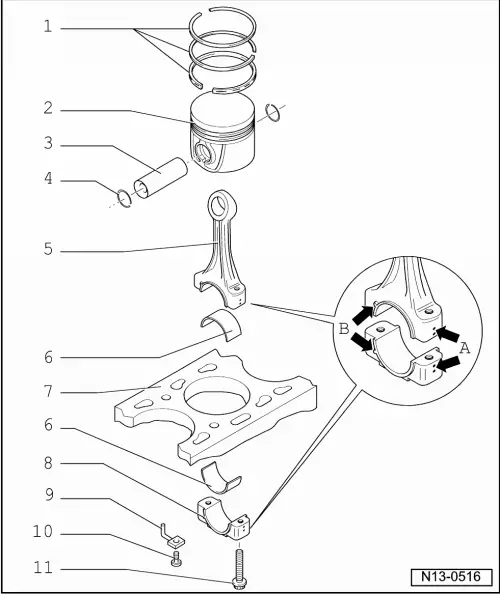

| 1 - | Piston rings |

| q | Offset gaps by 120° |

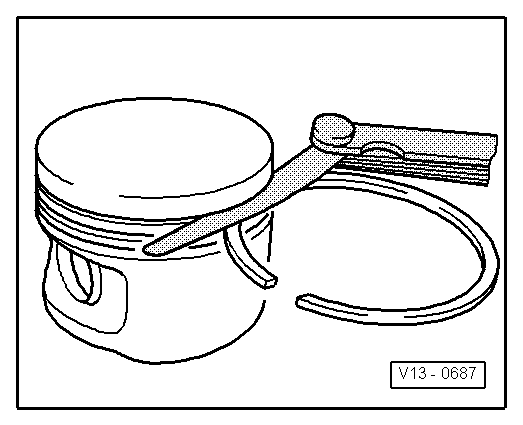

| q | Remove and install using piston ring clamp |

| q | Marking “TOP” or inscription must face piston crown. |

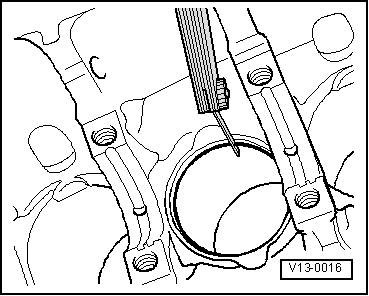

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

| 2 - | Piston |

| q | With combustion chamber |

| q | Mark installation position and cylinder allocation |

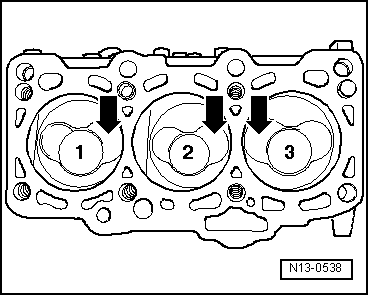

| q | Installation position and allocation of piston/cylinder → Fig. |

| q | Arrow on piston crown points to pulley end |

| q | If cracking is visible on piston skirt, renew piston |

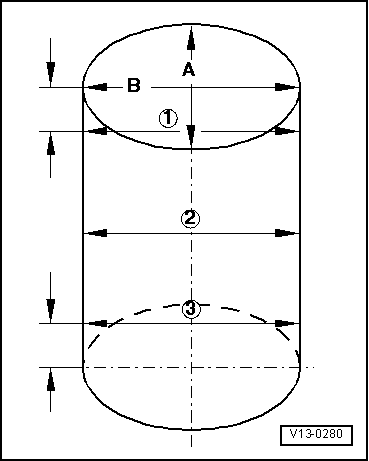

| q | Checking cylinder bore → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| q | Install using piston ring clamp |

| q | Checking piston projection at TDC → Chapter |

| 3 - | Piston pin |

| q | If difficult to remove, heat piston to 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 4 - | Circlip |

| 5 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder allocation -A- |

| q | Installation position: Marking -B- faces towards pulley end |

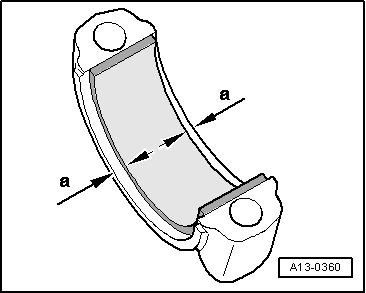

| 6 - | Bearing shell |

| q | Installation position → Fig. |

| q | Do not interchange used bearing shells (mark positions) |

| q | Note type: upper bearing shell (closest to piston) is constructed from more wear-resistant material. Distinguishing feature on new bearing shells: black marking on contact surface near separating point |

| q | Check that it is securely seated |

| q | Axial clearance: wear limit: 0.37 mm |

| q | Check radial clearance with Plastigage |

| q | Do not rotate crankshaft when checking radial clearance |

| q | Radial clearance: wear limit: 0.08 mm |

| 7 - | Cylinder block |

| q | Checking cylinder bore → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| 8 - | Conrod bearing cap |

| q | Note installation position |

| 9 - | Oil spray jet |

| q | For piston cooling |

| q | Note installation position: Turn oil spray jet anti-clockwise until it makes contact with cylinder block and secure in this position |

| 10 - | 27 Nm |

| q | Insert without sealant |

| 11 - | Conrod bolt, 30 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | Use old bolt for measuring radial clearance |

|

|

| Piston ring Dimensions in mm | New | Wear limit 1) | ||

| 1st compression ring | 0.20 … 0.35 | – | ||

| 2nd compression ring | 0.90 … 1.15 | – | ||

| Oil scraper ring | 0.25 … 0.50 | – | ||

| ||||

|

|

| Piston ring Dimensions in mm | New | Wear limit |

| 1stcompression ring | 0.06 … 0.09 | 0.25 |

| 2nd compression ring | 0.05 … 0.08 | 0.25 |

| Oil scraper ring | 0.03 … 0.06 | 0.15 |

Note

Note

|

|

|

|