A2

| Removing and installing toothed belt |

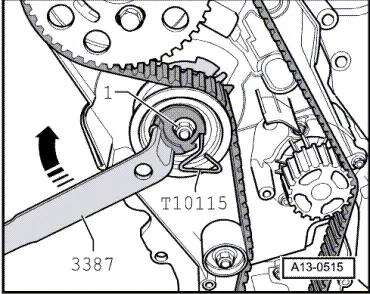

| Special tools and workshop equipment required |

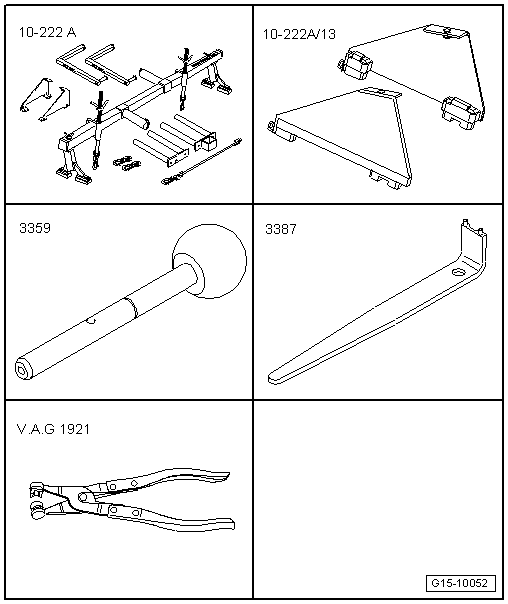

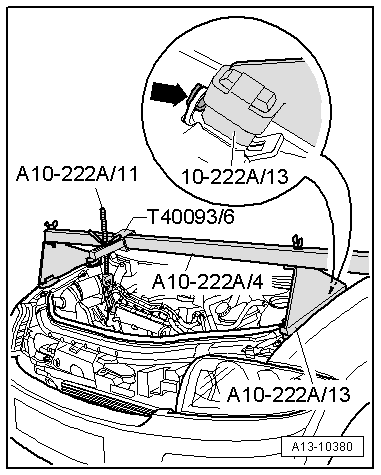

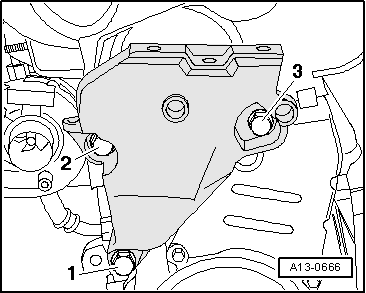

| t | Support bracket -10 - 222 A- |

| t | Adapter -10 - 222 A /13- |

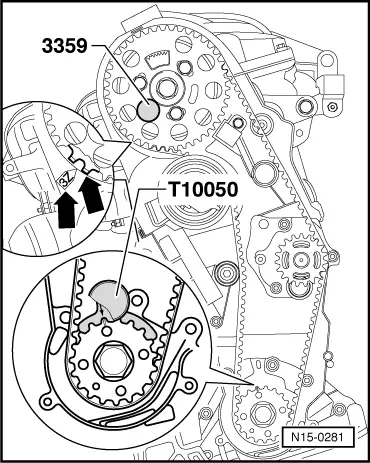

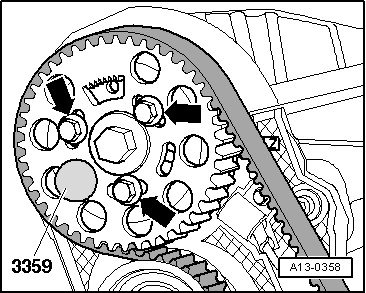

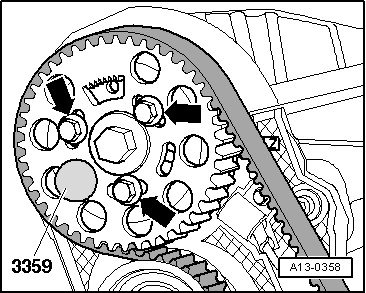

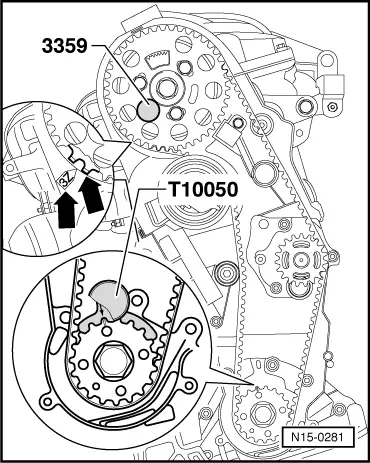

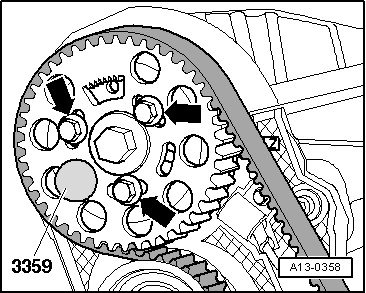

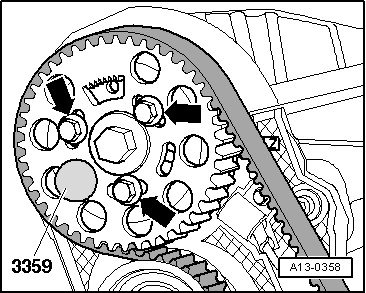

| t | Diesel injection pump locking pin -3359- |

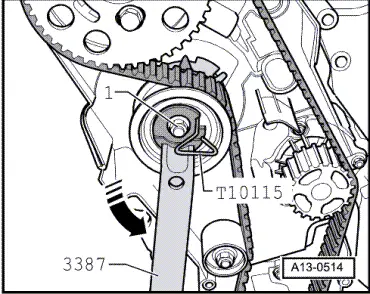

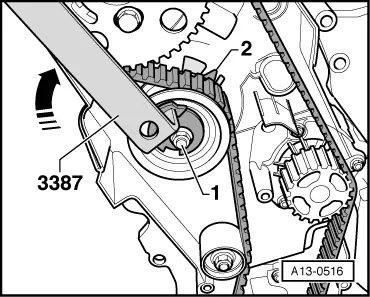

| t | Pin wrench -3387- |

| t | Hose clip pliers -V.A.G 1921- |

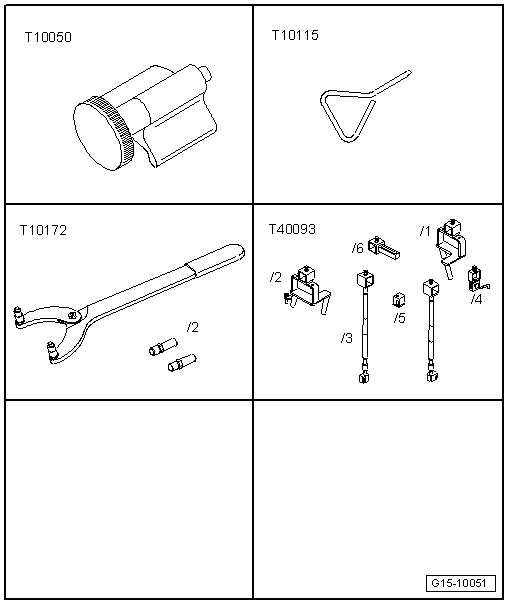

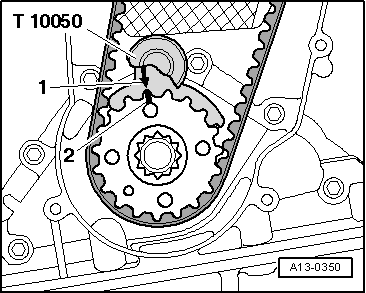

| t | Crankshaft stop -T10050- |

| t | Locking pin -T10115- |

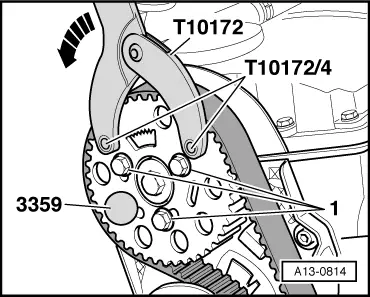

| t | Counterhold tool -T10172- with pin -T10172/4- |

| t | Adapter -T40093/6- from engine support bracket (supplementary set) -T40093- |

| t | Locking fluid → Parts catalogue |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

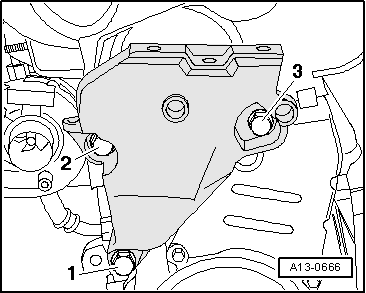

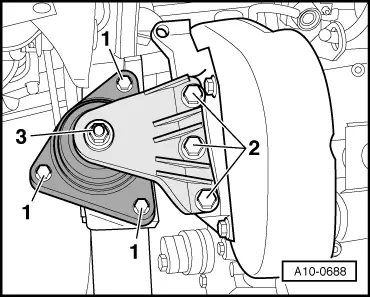

| Component | Nm | ||||

| Camshaft sprocket to hub | 25 | ||||

| Tensioning roller for toothed belt to cylinder head | 20 + 45° 1) | ||||

| Toothed belt cover (bottom) to cylinder block | 10 2) | ||||

| Toothed belt cover (centre) to cylinder block | 10 2) | ||||

| Engine support to cylinder block | 45 | ||||

| Tensioner for poly V-belt to bracket for ancillaries | 22 | ||||

| Engine cover panel to bracket | 5.5 | ||||

| |||||

Caution

Caution