A2

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

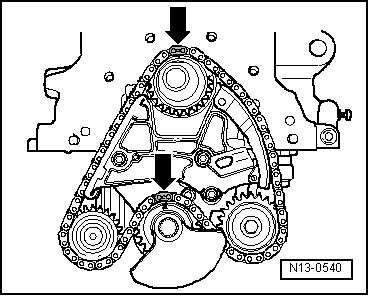

| Component | Nm | ||||||

| Retaining frame with balance shaft to cylinder block | 14 + 180° 1)2) | ||||||

| Balance weight with chain sprocket to retaining frame | 100 + 90° 1)3) | ||||||

| Chain tensioner to retaining frame | 8 + 90° 1)3) | ||||||

| Idler sprocket to retaining frame | 20 | ||||||

| Baffle plate to retaining frame | 5 | ||||||

| |||||||