A2

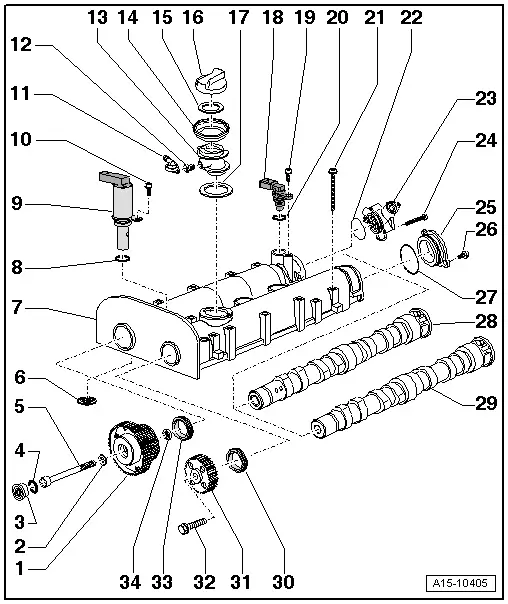

| Camshaft housing - exploded view |

| 1 - | Inlet camshaft sprocket with camshaft adjuster |

| q | Do not dismantle |

| q | Removing and installing → Chapter |

| 2 - | Washer |

| 3 - | Screw plug |

| q | 25 Nm |

| 4 - | O-ring |

| q | Renew if damaged |

| 5 - | Bolt |

Caution

Caution

|

| q | Renew |

| q | Lubricate threads and contact surface of bolt head with oil |

| q | 40 Nm + turn 90° further |

| 6 - | Oil strainer |

| q | Inserted in cylinder head |

| q | Renew |

| 7 - | Camshaft housing |

| q | With integrated camshaft bearings |

| q | Removing and installing → Chapter |

| q | Remove old sealant residues |

| q | Carefully clean sealing surfaces; they must be free of oil and grease |

| q | Coat with sealant before installing; for sealant refer to → Electronic parts catalogue |

| q | Installing: fit vertically from above onto studs and dowel pins |

| 8 - | O-ring |

| q | Renew |

| 9 - | Camshaft control valve 1 -N205- |

| 10 - | Bolt |

| q | 10 Nm |

| 11 - | Non-return valve |

| 12 - | Rubber grommet |

| 13 - | Oil filler neck |

| 14 - | Sealing collar |

| q | Renew if damaged |

| 15 - | Seal |

| q | Renew if damaged |

| 16 - | Filler cap |

| 17 - | Seal |

| q | Renew |

| 18 - | Hall sender -G40- |

| 19 - | Bolt |

| q | 10 Nm |

| 20 - | O-ring |

| q | Renew |

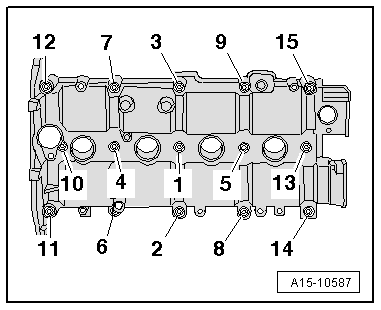

| 21 - | Bolt |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Tightening torque and sequence → Fig. |

| 22 - | O-ring |

| q | Renew |

| 23 - | High-pressure pump with fuel pressure regulating valve -N276- |

| q | Removing and installing → Rep. gr.24 |

| 24 - | Bolt |

| q | Tightening torque → Rep. gr.24 |

| 25 - | Sealing cap |

| 26 - | Bolt |

| q | 10 Nm |

| 27 - | O-ring |

| q | Renew |

| 28 - | Inlet camshaft |

| q | With cam for high-pressure pump |

| q | Before removing, detach roller tappet for high-pressure pump |

| q | Checking axial clearance → Chapter |

| q | Removing and installing → Chapter |

| q | Lubricate with oil before installing (also lubricate collar of axial bearing) |

| 29 - | Exhaust camshaft |

| q | Checking axial clearance → Chapter |

| q | Removing and installing → Chapter |

| q | Lubricate with oil before installing (also lubricate collar of axial bearing) |

| 30 - | Oil seal |

| q | For exhaust camshaft |

| q | Renewing → Chapter |

| 31 - | Exhaust camshaft sprocket |

| q | Removing and installing → Chapter |

| 32 - | Bolt |

| q | Renew |

| q | 20 Nm + turn 90° further |

| 33 - | Oil seal |

| q | For inlet camshaft sprocket with camshaft adjuster |

| q | Renewing → Chapter |

| 34 - | Washer |

| q | Not fitted on later versions → Electronic parts catalogue |

| q | If a washer was originally fitted, renew washer and install again |

|

|