A2

| Checking for leaks |

| Special tools and workshop equipment required |

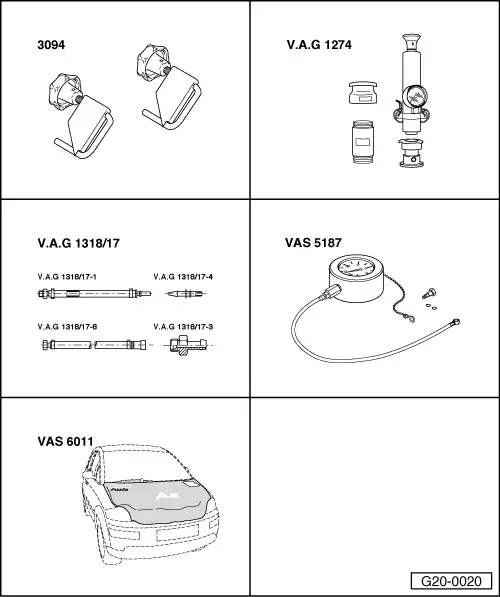

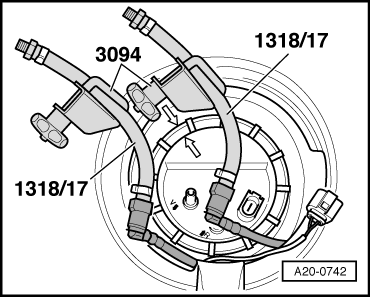

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

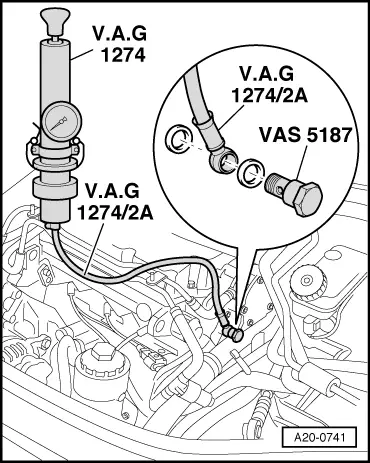

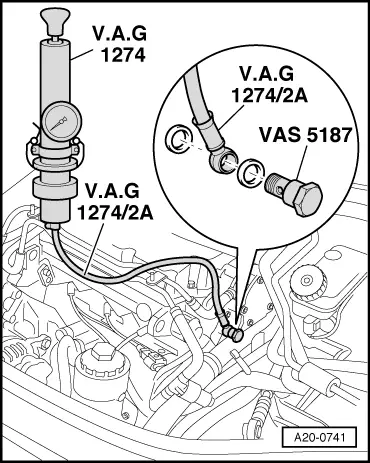

| t | Cooling system tester -V.A.G 1274- with -V.A.G 1274/2 A- |

| t | Adapter -V.A.G 1318/17-1- from adapter set -V.A.G 1318/17- (2 x) |

| t | Tandem pump tester -VAS 5187- |

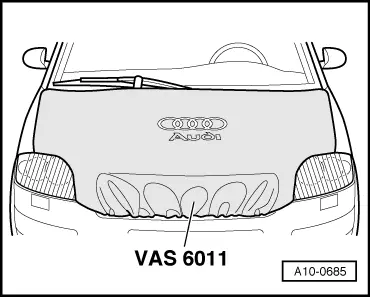

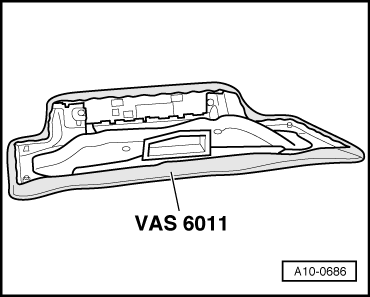

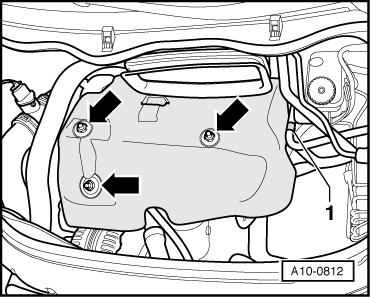

| t | Audi A2 engine cover protector -VAS 6011- |

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING