| –

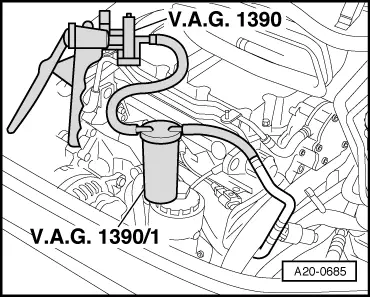

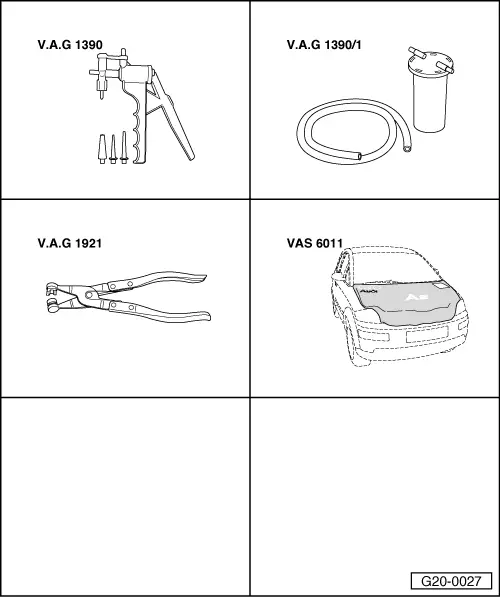

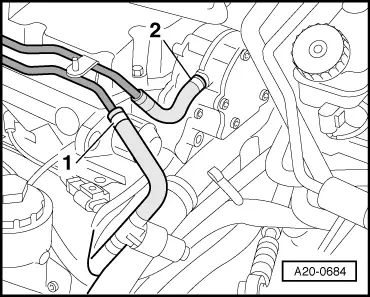

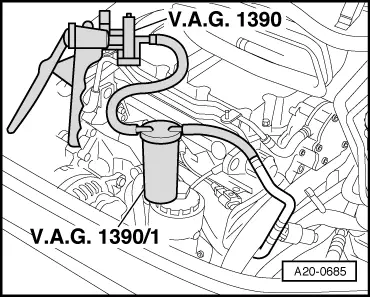

| Insert a suitable adapter from the hand-operated vacuum pump -V.A.G 1390- into the short length of hose on the return pipe. |

| –

| Connect adapter with short length of hose and bleeder container -V.A.G 1390/1-. |

| –

| Connect hand-operated vacuum pump -V.A.G 1390- with bleeder container -V.A.G 1390/1- to return hose. |

| –

| Operate hand-operated vacuum pump until no more fuel comes out of return hose. Make sure no fuel is sucked into hand-operated vacuum pump. |

Note | Instead of hand-operated vacuum pump -V.A.G 1390- with bleeder container -V.A.G 1390/1-, you can also use diesel extractor -VAS 5226-. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING