|

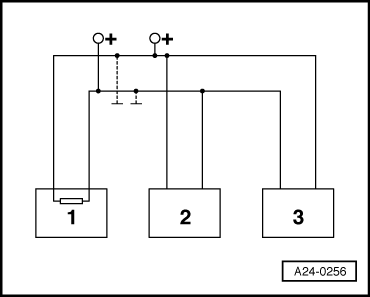

If faults have been stored relating to the "Drive train data bus" or to the "CAN data bus":

-

‒ Check that the engine control unit, gearbox control unit, ABS/EDL control unit and airbag control unit or the dash panel insert are the correct versions for the vehicle (check Part No. and coding).

If the correct control units are installed:

-

‒ Check that multi-pin connectors for control units are properly seated.

If the multi-pin connectors are properly seated:

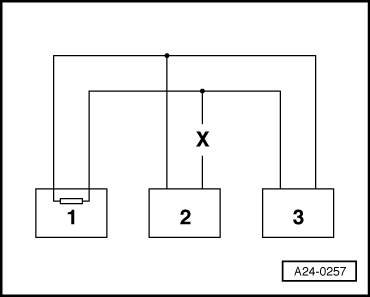

Testing a "two-wire bus system"

Three or more control units communicating via a "two-wire bus system"

-

‒ Read out the faults stored in the control units.

Note:

This will help to trace a fault in the wiring.

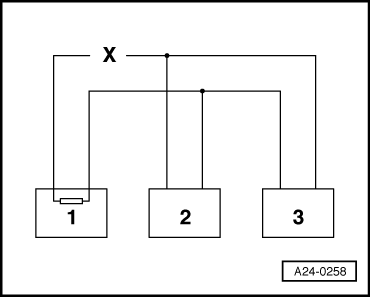

Example 1:

From the faults present in the fault memories, you can see that control unit 1 has no connection to control units 2 or 3.

|