A3 Mk1

|

| Special tools and workshop equipment required |

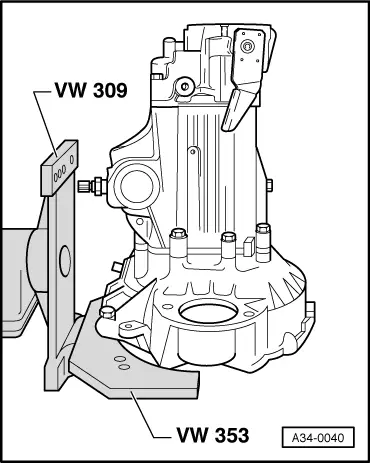

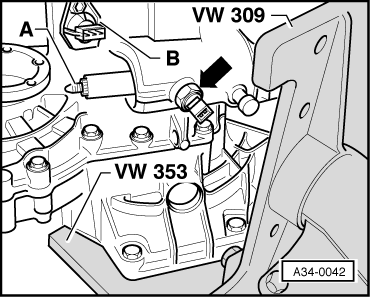

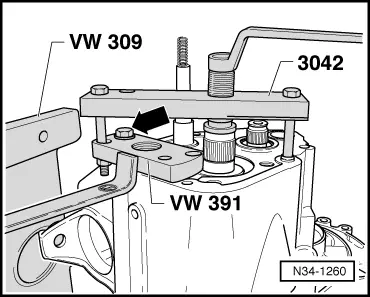

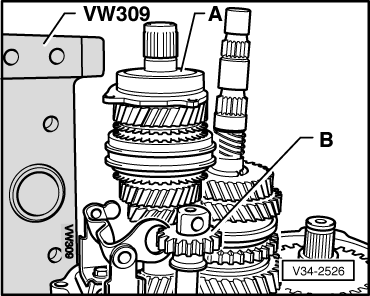

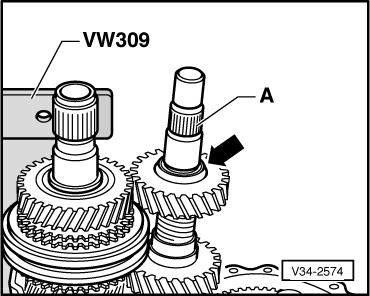

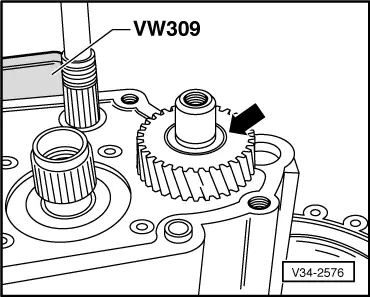

| t | Support plate -VW 309- |

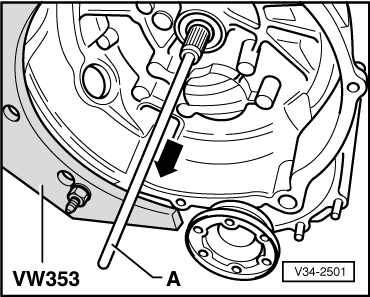

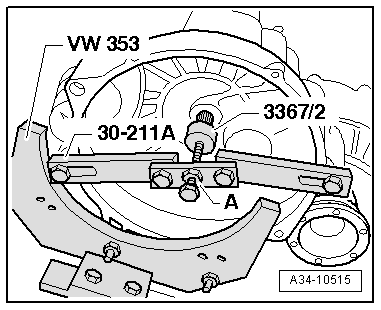

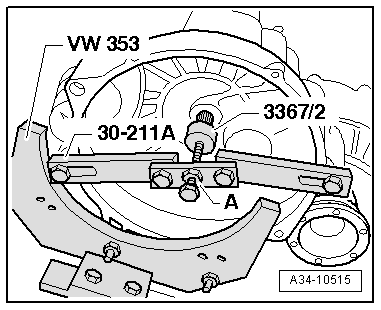

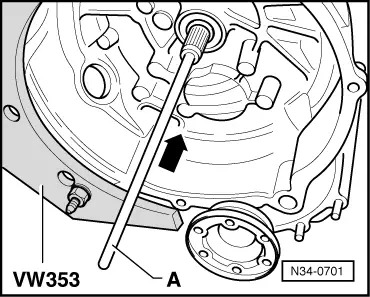

| t | Gearbox support -VW 353- |

| t | Support bridge -30 - 211 A- |

| t | Fitting tool -3367/2- |

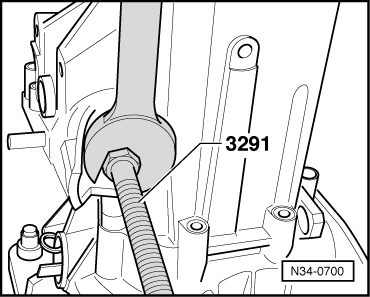

| t | Spindle -3291- |

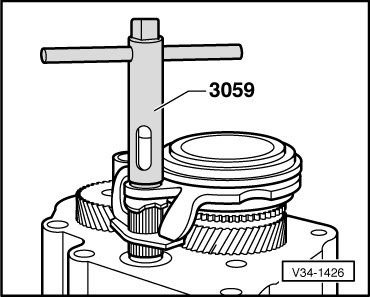

| t | Box wrench -3059- |

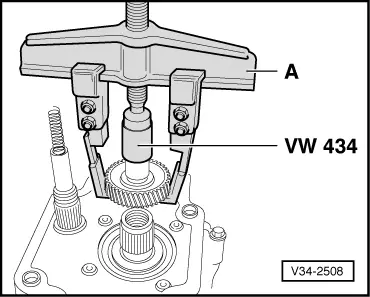

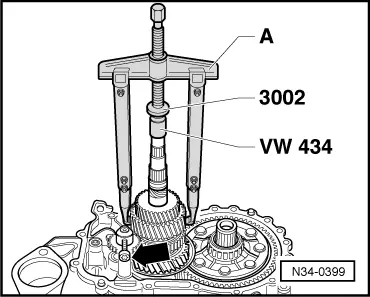

| t | Press tool -VW 434- |

| t | Puller -3042- |

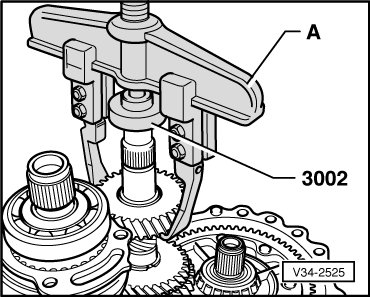

| t | Thrust piece -3002- |

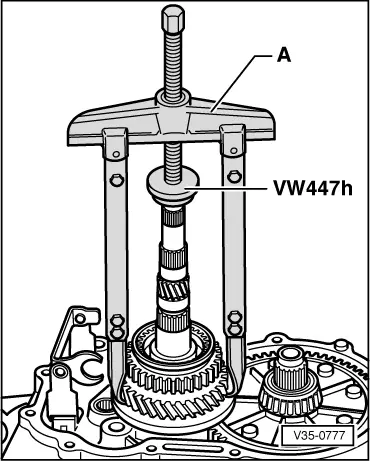

| t | Thrust plate -VW 447 H- |

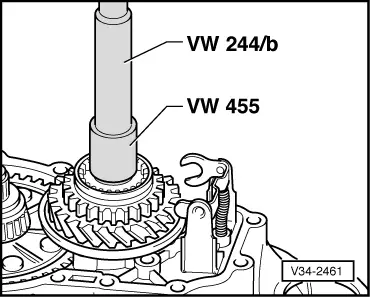

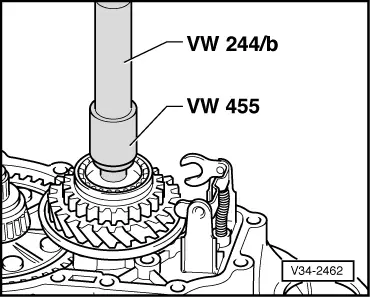

| t | Drift sleeve -VW 244 B- |

| t | Installing sleeve -VW 455- |

| t | Drive flange installing tool -VW 391- |

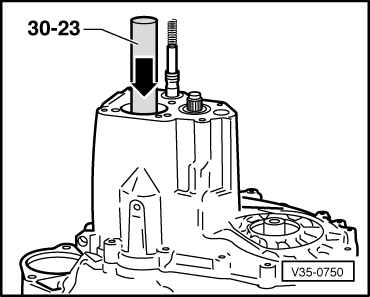

| t | Extension -30 - 23- |

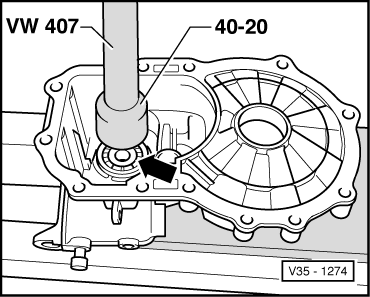

| t | Drift sleeve -40 - 20- |

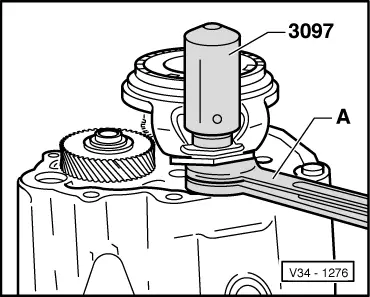

| t | Fitting tool -3097- |

| t | Torque wrench -V.A.G 1331- |

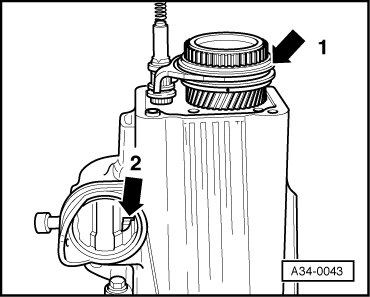

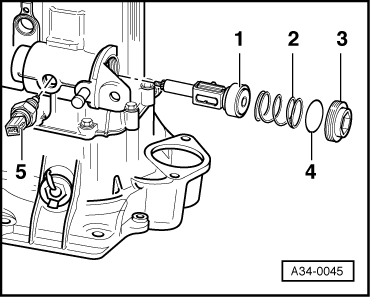

| t | -1-Two-arm puller -Kukko 20/10- |

| t | -2-Matra hooks -V/170- |

| t | -2-Puller hook -Kukko 1-250- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

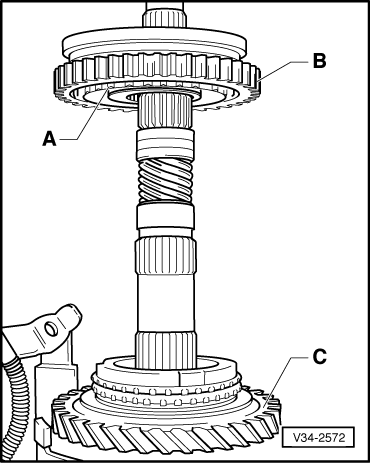

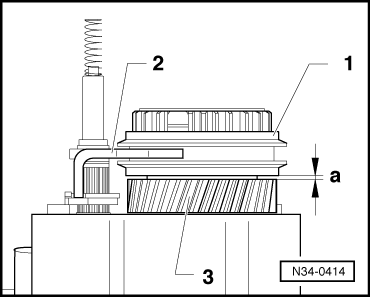

| Thickness (mm) | Identification |

| 2.5 | Brown |

| 2.6 | Black |

| 2.7 | Bright metal |

| 2.8 | Copper |

| 2.9 | Brass |

| 3.0 | Blue |

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|