A3 Mk1

| Servicing clutch housing |

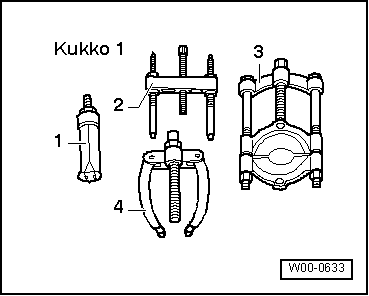

| Special tools and workshop equipment required |

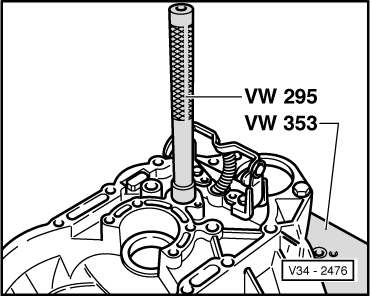

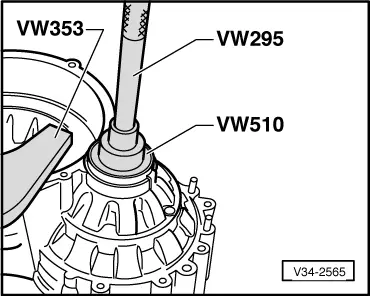

| t | Drift -VW 295- |

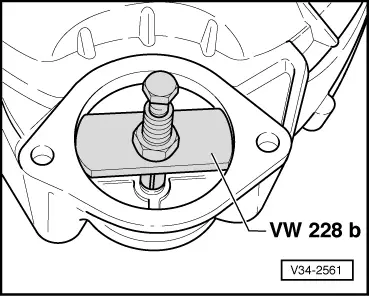

| t | Extractor -VW 228 B- |

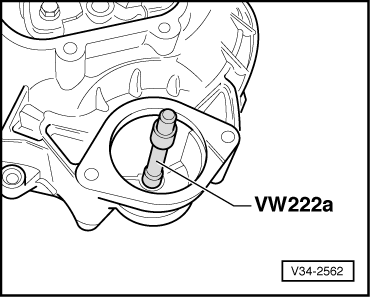

| t | Drift -VW 222 A- |

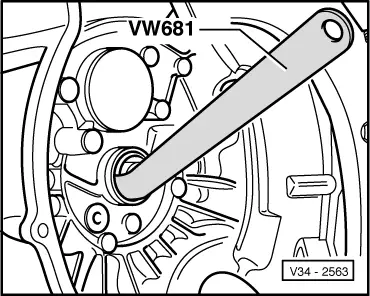

| t | Puller hook -T20143/1- or oil seal extractor lever -VW 681- |

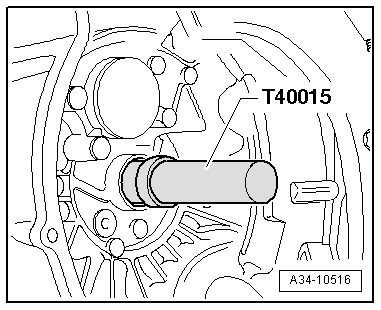

| t | Thrust piece -T40015- |

| t | Thrust pad -VW 510- |

|

|

|

|

| 1 - | Oil drain plug |

| q | 25 Nm |

| q | Without magnet |

| 2 - | Dowel sleeve |

| q | 2x |

| 3 - | Shim “S2” |

| q | Always 1 mm thick |

| 4 - | Tapered roller bearing outer race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed: adjust differential → Chapter |

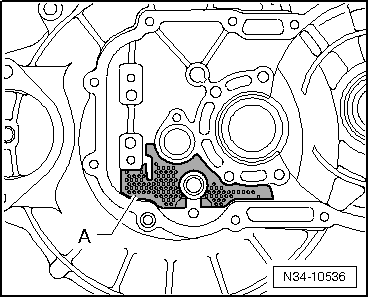

| 5 - | Magnet |

| q | Held in place by joint surface of housing |

| q | Apply sealant -AMV 188 200 03- when installing |

| 6 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Chapter |

| 7 - | Tapered roller bearing outer race |

| q | For output shaft |

| q | Removing and installing → Chapter |

| q | If renewed: Adjust output shaft → Chapter |

| 8 - | Needle bearing |

| q | For input shaft |

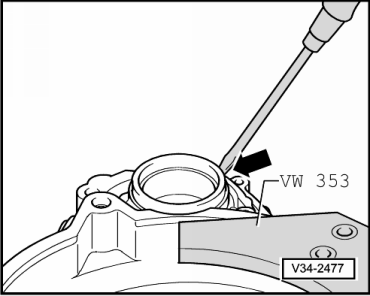

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 9 - | Bolt |

| q | 25 Nm |

| q | With serrations under bolt head |

| 10 - | Reverse lever |

| 11 - | Spring |

| 12 - | Reverse lever support |

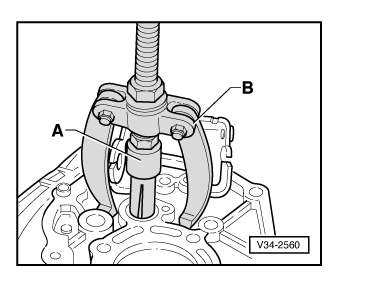

| 13 - | Sliding piece |

| 14 - | Starter bush |

| q | Not fitted on all gearboxes |

| q | Allocate according to → Electronic parts catalogue |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Can be renewed with gearbox in vehicle |

| 15 - | Screw plug |

| q | Green - Clutch diameter 210 mm |

| q | White - Clutch diameter 190 and 200 mm |

Note

Note| It is important to allocate parts correctly, for example when fitting a replacement gearbox or transferring a clutch. |

| Consequences if incorrect plugs are installed: |

| 1. White sealing plug - 210 mm Ø clutch |

| – | The TDC sender will be destroyed and the markings on the flywheel will be damaged. Parts of the TDC-sender will remain in the clutch chamber. |

| 2. Green sealing plug - 190 and 200 mm Ø clutch |

| – | Tester does not display a readout or readout is inaccurate or fluctuates. |

| 16 - | Cap |

| 17 - | Clutch housing |

| q | Install oil strainer → Fig.. |

| q | If replaced: → Chapter „Table of adjustments“ |

| 18 - | Input shaft oil seal |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 19 - | Sleeve |

| q | For oil seal → Item |

| q | Removing → Fig. |

| q | Driving in → Fig. |

| 20 - | Oil seal |

| q | For flange shaft |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|