A3 Mk1

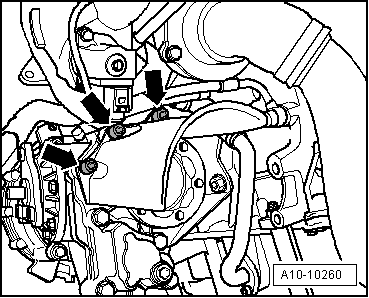

| Renewing needle bearings (polygon bearings) for flange shaft (right-side) with bevel box installed |

| Special tools and workshop equipment required |

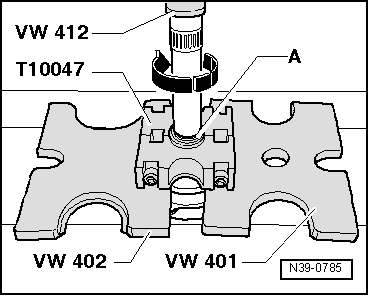

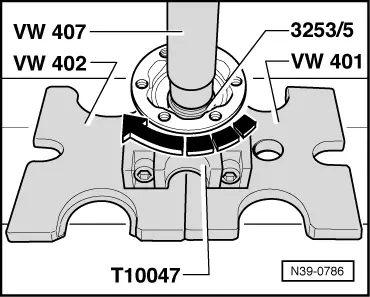

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Assembly tool -VAS 3253- |

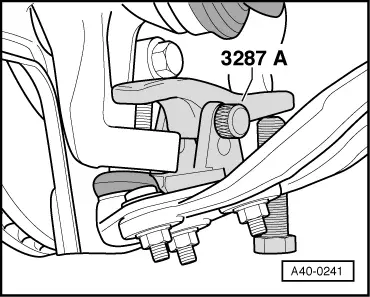

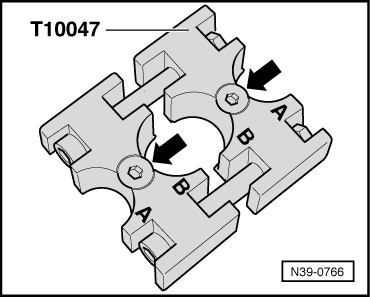

| t | Tensioning tool -T10047- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm |

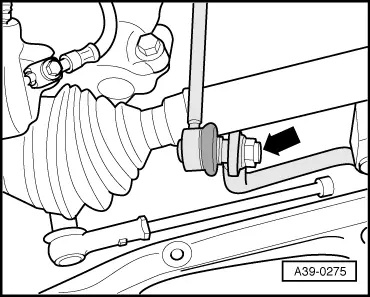

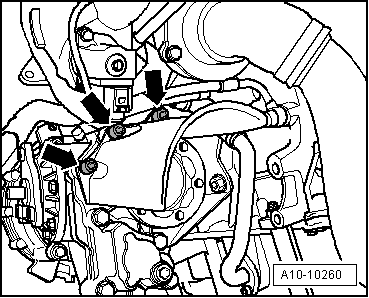

| Flange shaft to gearbox (countersunk bolt) | 25 |

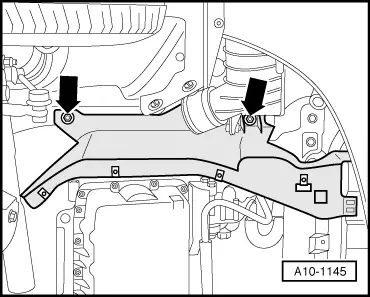

| Heat shield for drive shaft to bevel box | 25 |