| –

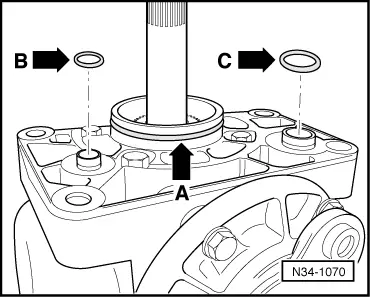

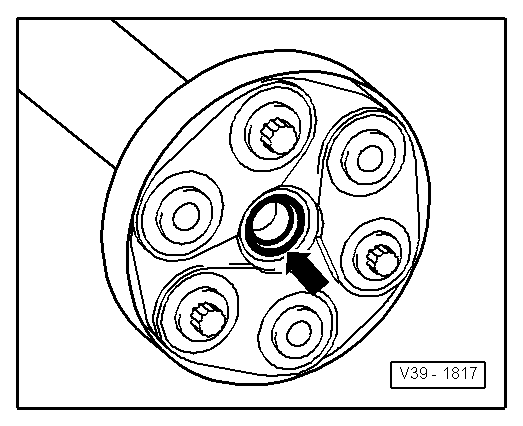

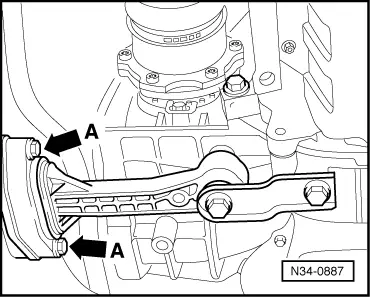

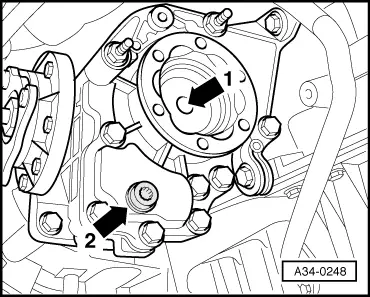

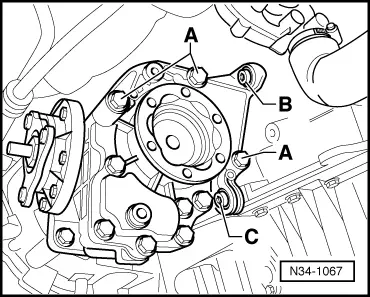

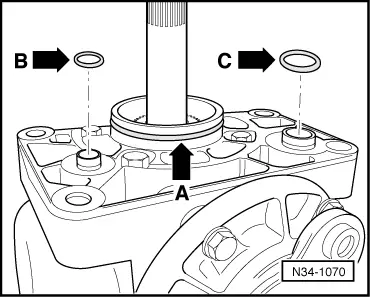

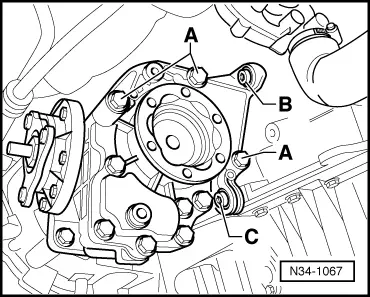

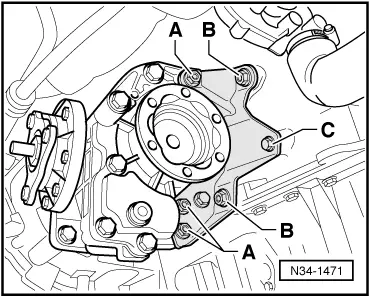

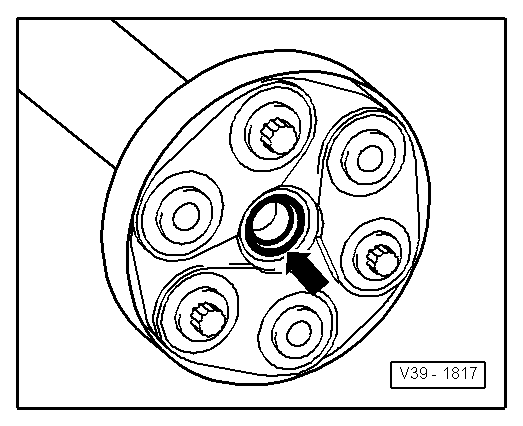

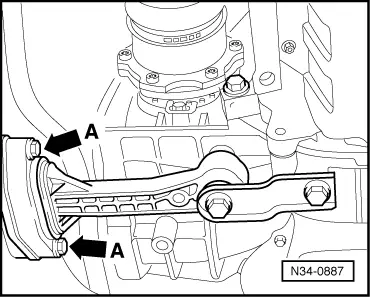

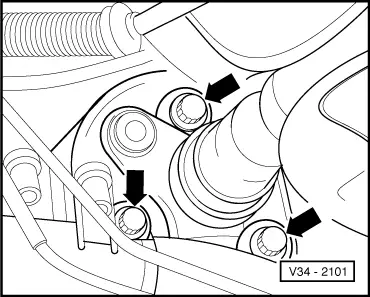

| Always renew O-ring between bevel box and gearbox -arrow A- and seals on oil supply drillings -arrow B, C-. |

| –

| Lightly lubricate O-ring and seals prior to installing. |

| –

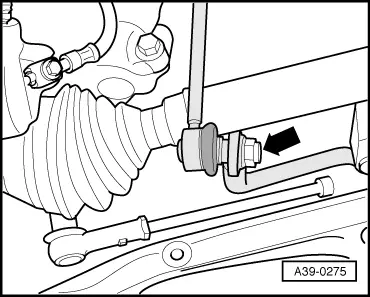

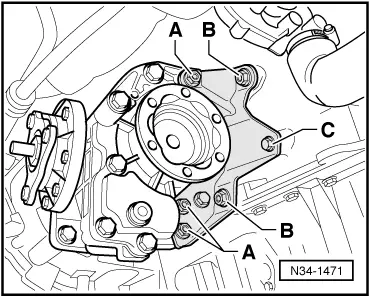

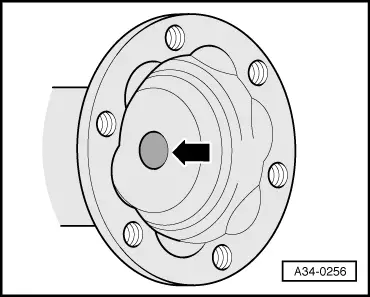

| Push bevel box completely onto gearbox, at the same time ensuring that the splines on the bevel box input shaft are guided centrally onto the differential connecting piece. |

| l

| If the splines are correctly positioned and the components are located centrally, the bevel box will slide against the gearbox onto the stop. |

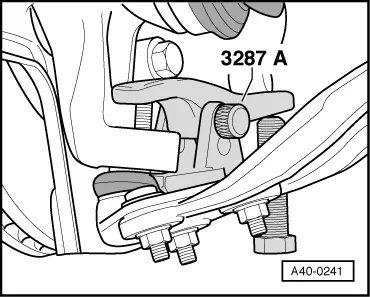

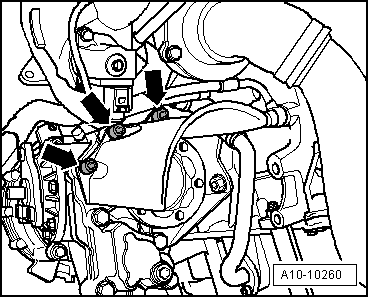

Note | Do not use the securing bolts to pull the bevel box onto the gearbox. This could cause the bevel box to tilt and the securing eyes may break off. |

| –

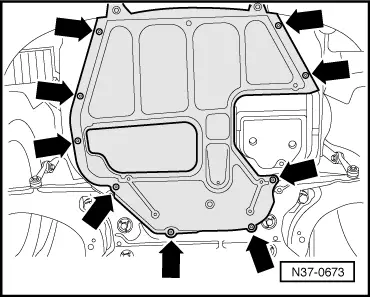

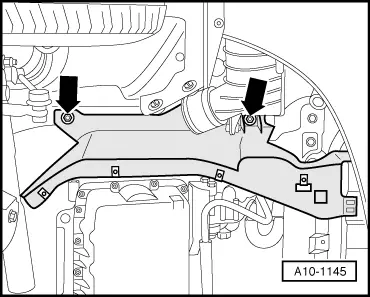

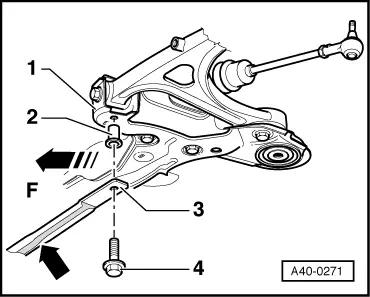

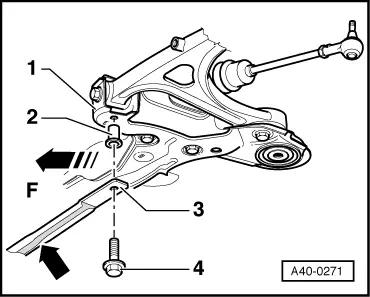

| Install bevel box bracket prior to fitting bevel box/gearbox securing bolts. |

| –

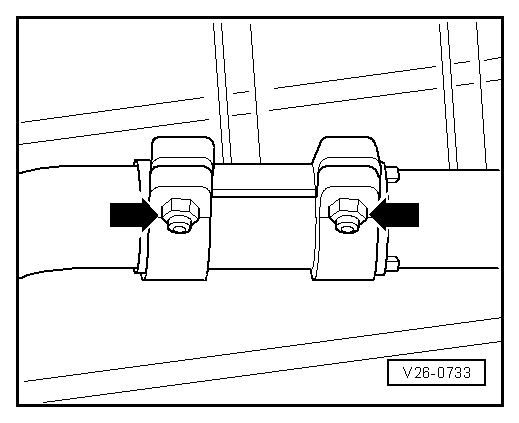

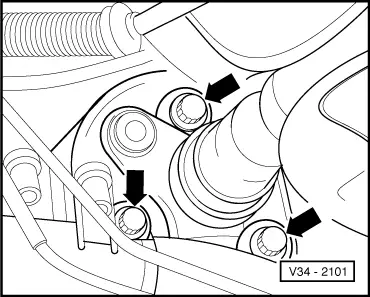

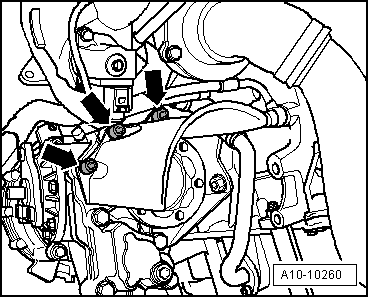

| Tighten new securing bolts between bevel box and gearbox. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution