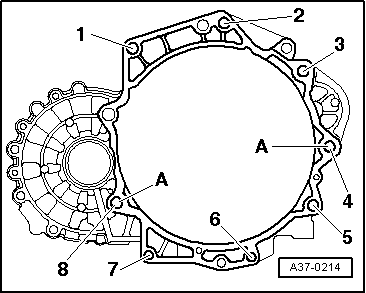

| Component | Nm |

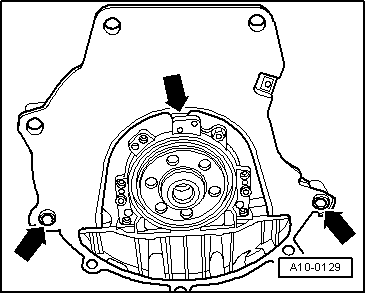

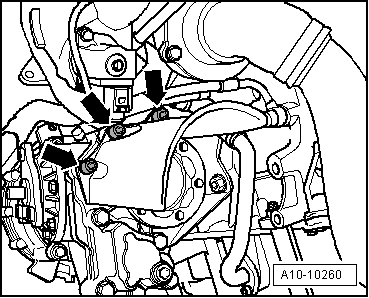

| Flywheel cover plate to gearbox | 10 |

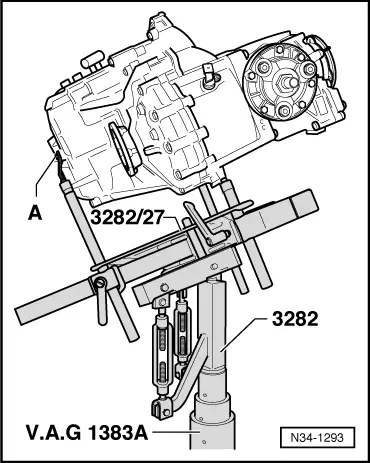

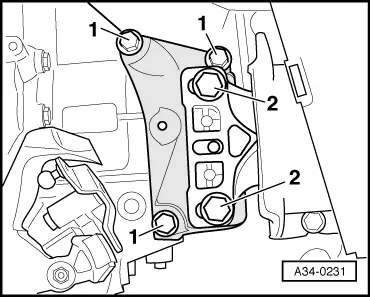

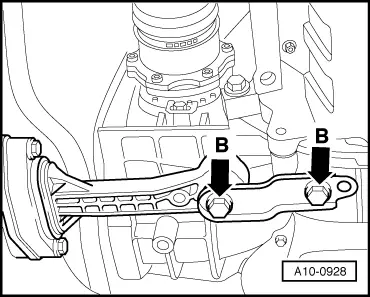

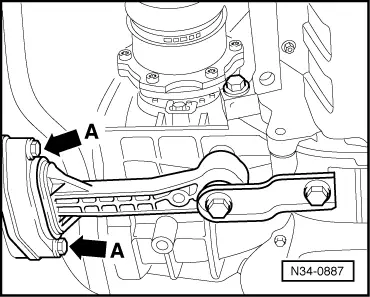

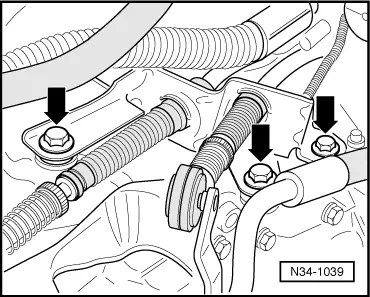

| Gearbox support to gearbox | 40 + 90° 1) 2) |

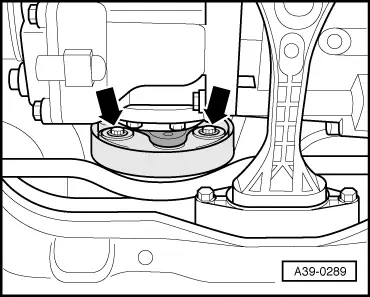

| Gearbox console to gearbox mounting | 60 + 90° 1) 2) |

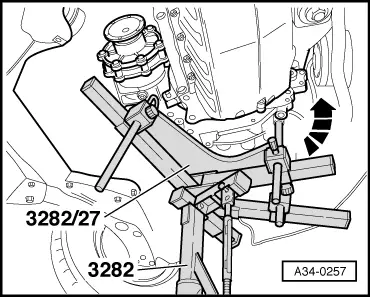

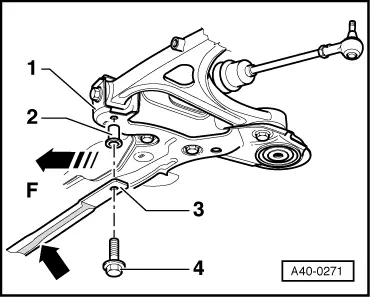

| Pendulum support to | gearbox | 40 + 90° 1) 2) |

| | subframe | 20 + 90° 1) 2) |

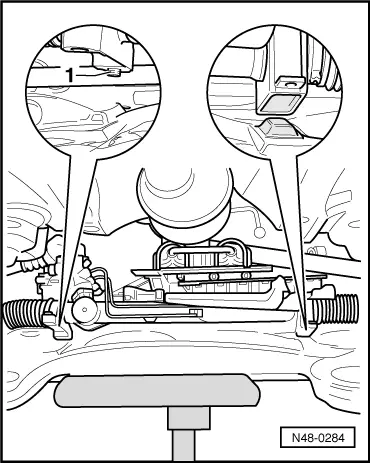

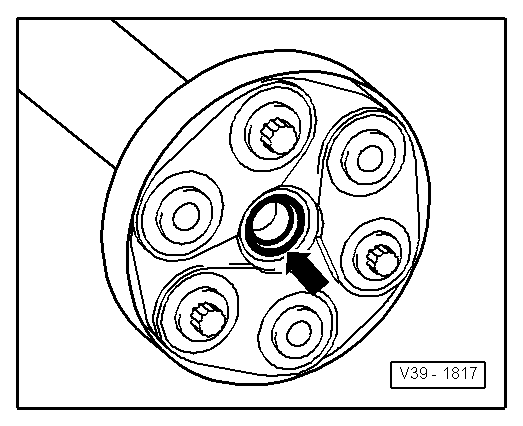

| Cross piece to subframe (if fitted) | 30 + 90° 1) 2) 4) |

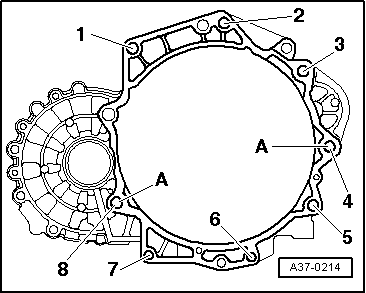

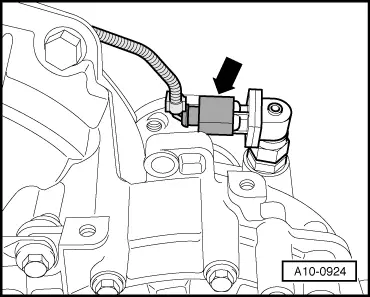

| Heat shield to gearbox | 25 |

| Heat shield to gearbox | 25 |

| Flywheel cover plate to gearbox | 10 |

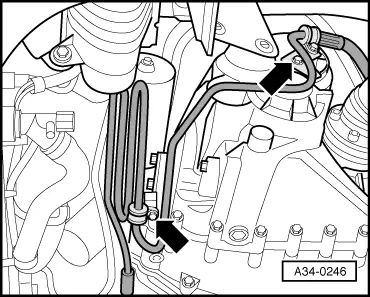

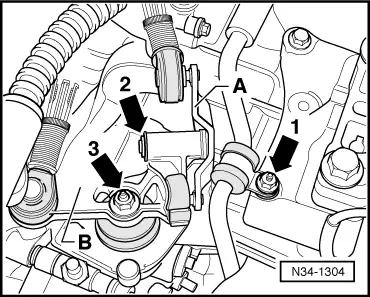

| Pressure pipe of power steering to gearbox support | 22 |

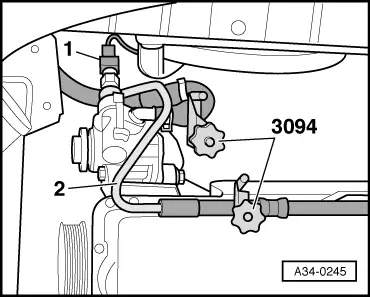

| Selector cable support bracket to gearbox | 23 |

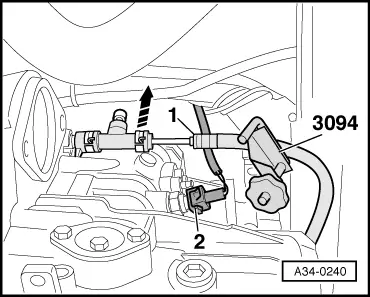

| Selector shaft lever to selector shaft | 20 3) |

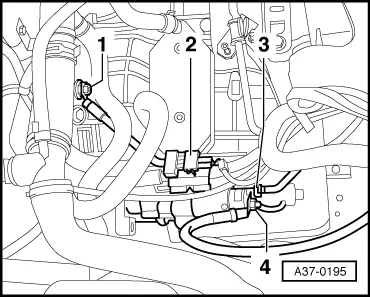

| Air cleaner housing to body | 10 |

| Air pipe to longitudinal member | 10 |

| l

| 2) 90° = one quarter turn |

| l

| 4) Apply locking fluid -D 000 600 A2- when fitting |

|

Note

Note

Caution

Caution WARNING

WARNING