A3 Mk1

|

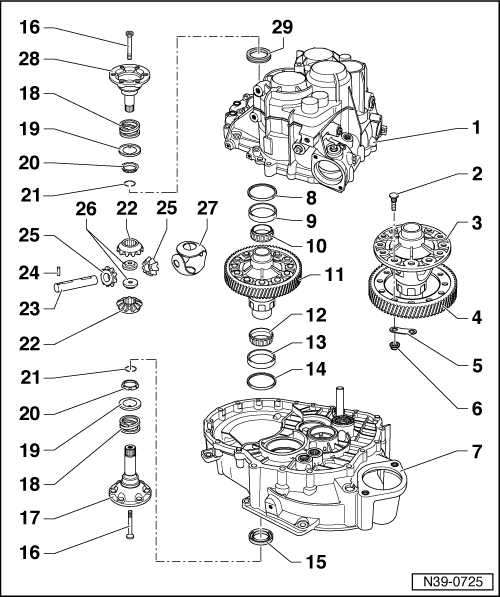

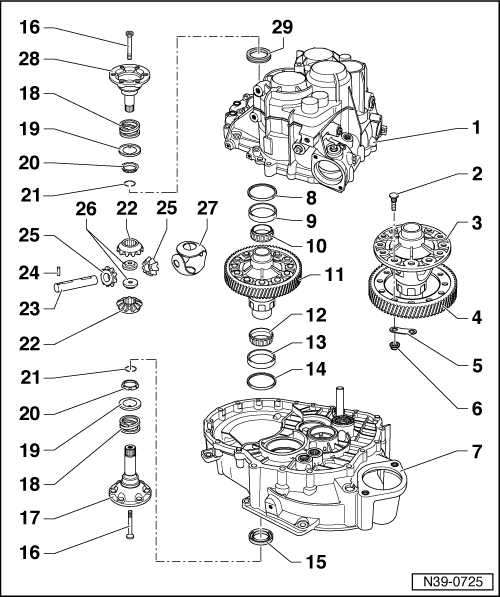

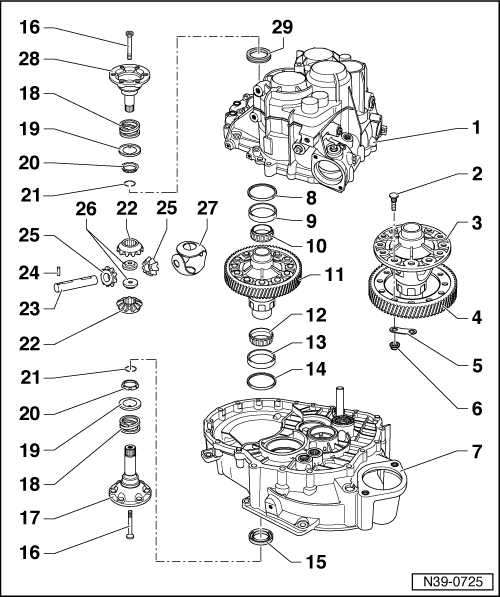

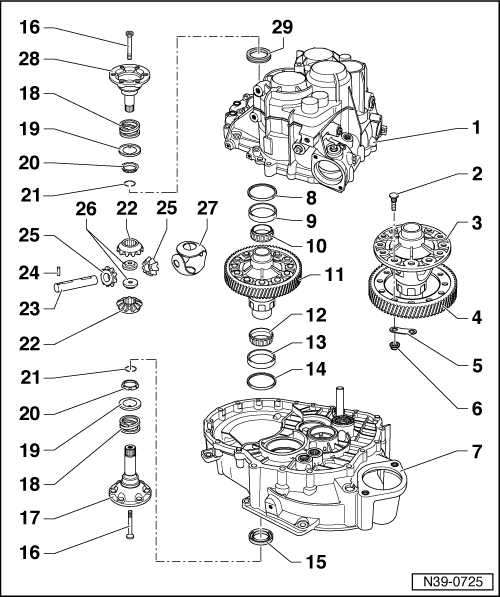

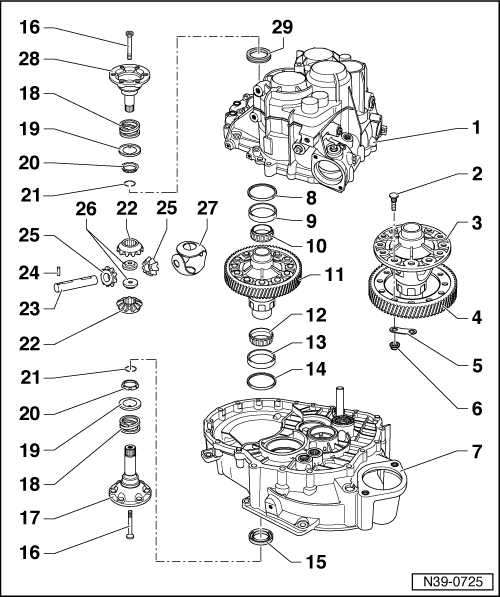

Dismantling and assembling differential

Dismantling and assembling differential

|

|

|

|

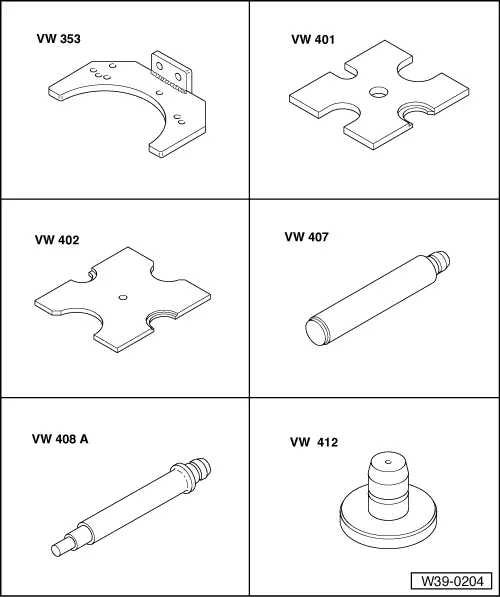

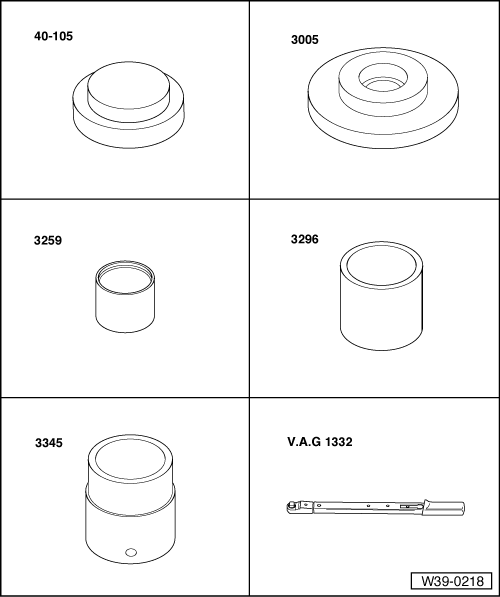

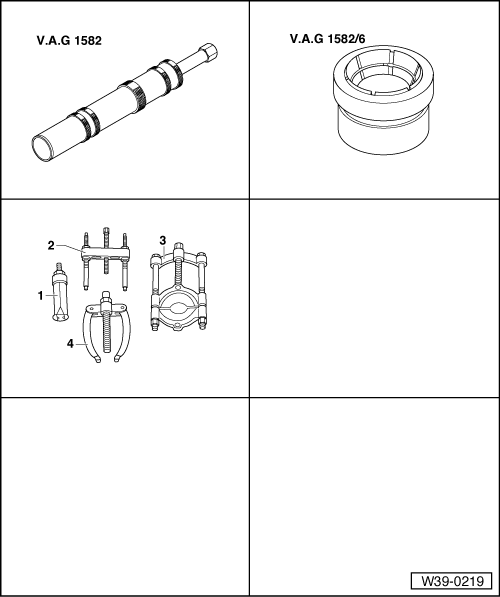

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

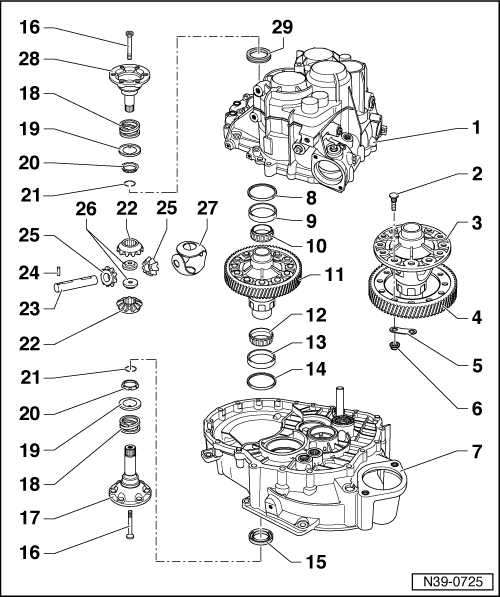

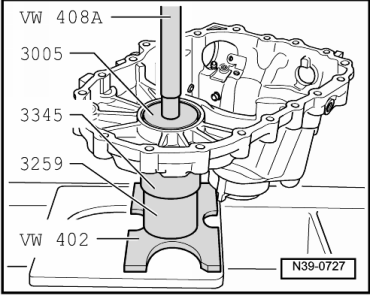

→ Fig.2 Pressing taper roller bearing outer race into clutch housing

|

|

|

|

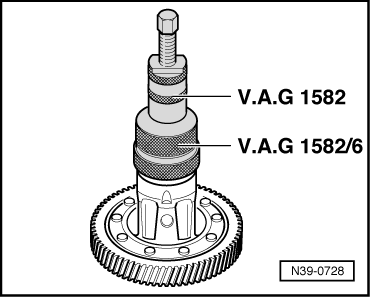

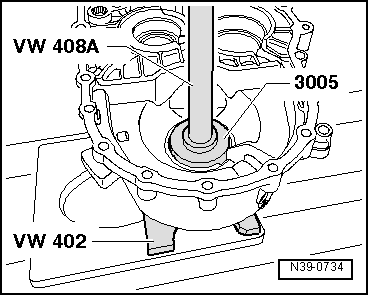

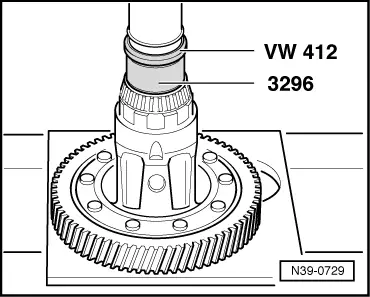

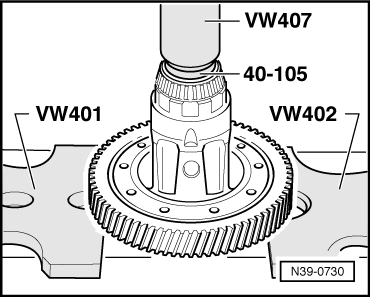

→ Fig.4 Pressing on taper roller bearing inner race Note: The taper roller bearing inner races for gearbox housing and clutch housing are pressed on with the same press tools. |

|

|

|

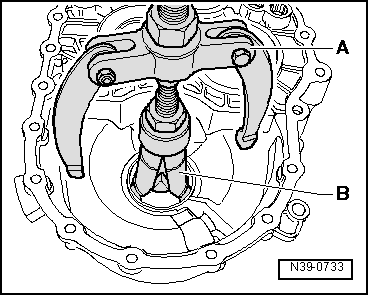

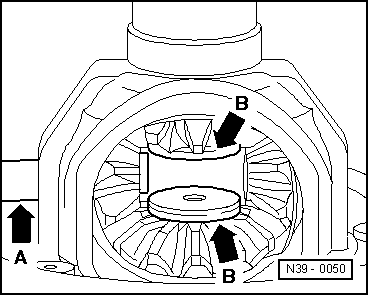

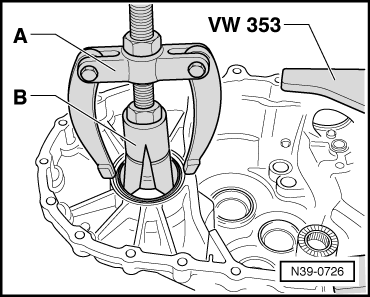

→ Fig.5 Pulling taper roller bearing outer race out of gearbox housing A - Counter support, e.g. Kukko 22/2 B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

→ Fig.6 Pressing taper roller bearing outer race into gearbox housing

|

|

|

|

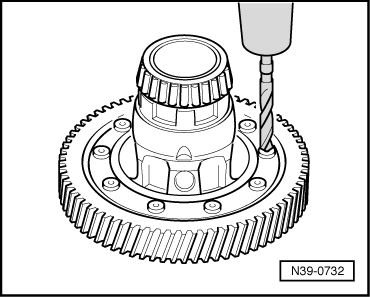

→ Fig.8 Pressing off final drive gear

|

|

|

|

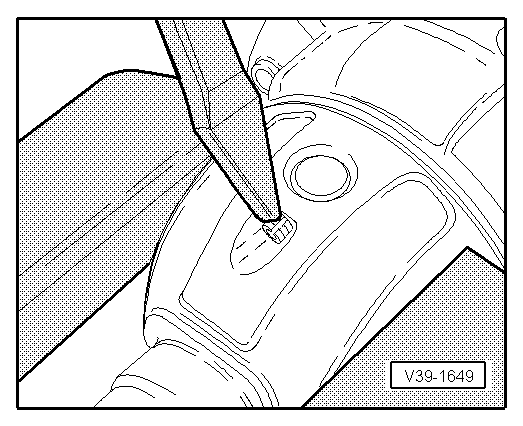

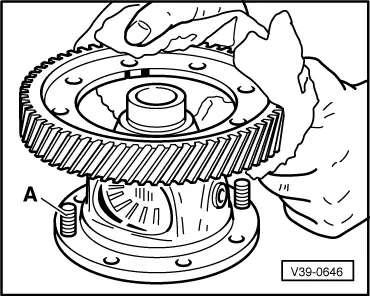

→ Fig.9 Heating final drive gear wheel to approx. 100 °C and installing

|

|

|

|

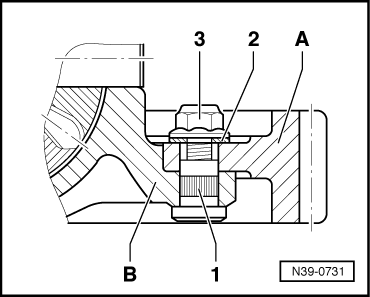

→ Fig.10 Bolting final drive gear -A- and differential housing -B- together Use special bolts -1- with backing plates -2- and nuts -3- according to parts catalogue. |