A3 Mk1

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

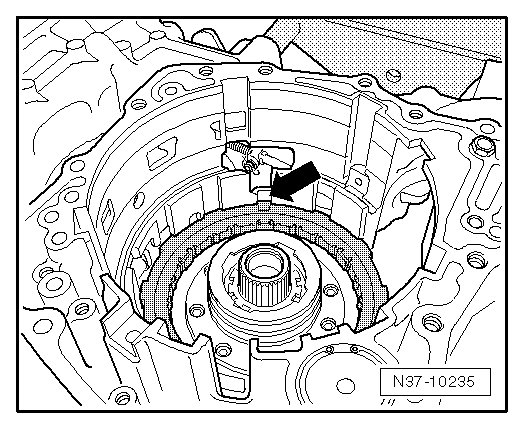

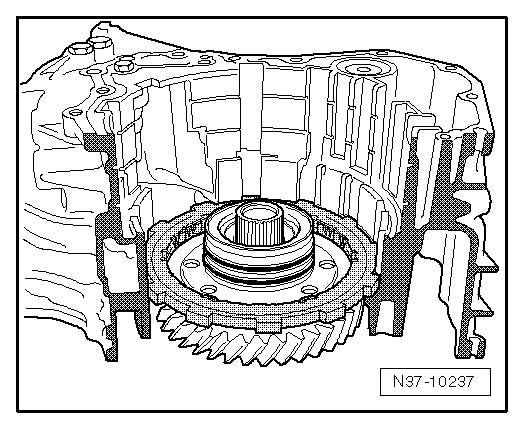

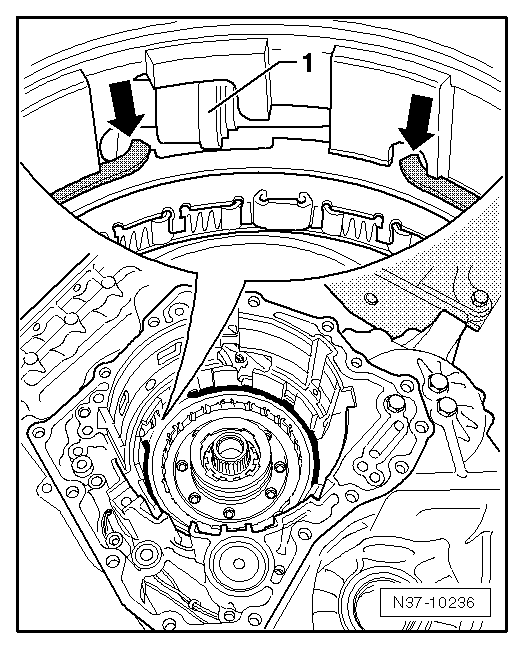

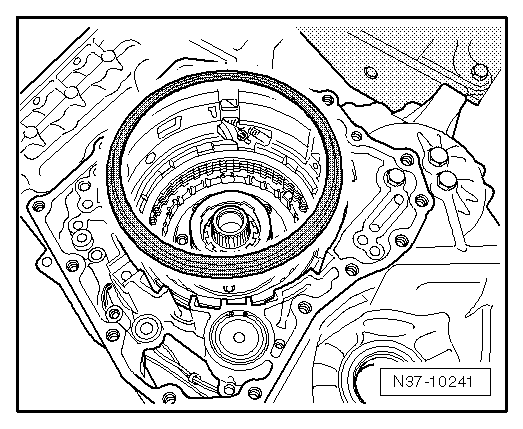

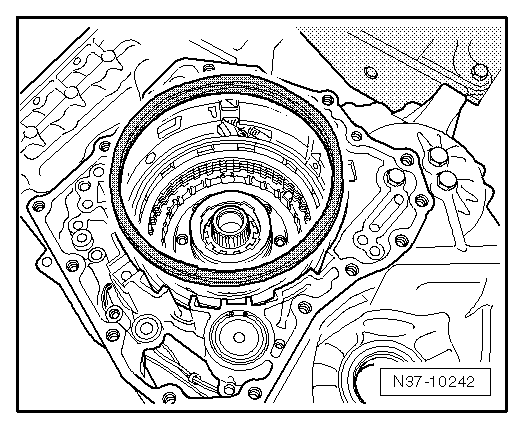

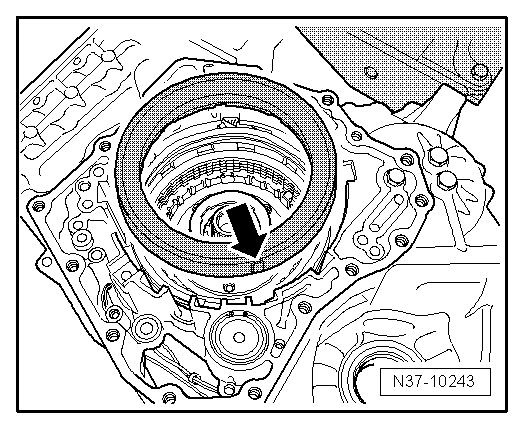

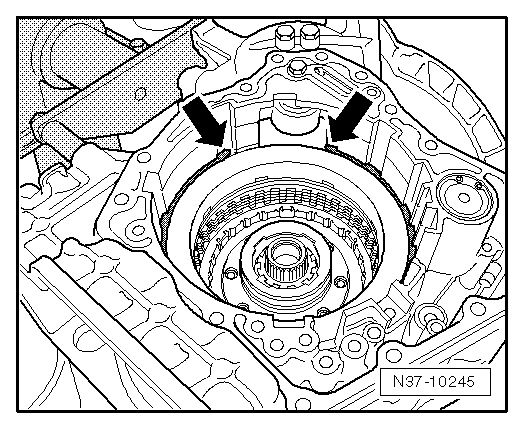

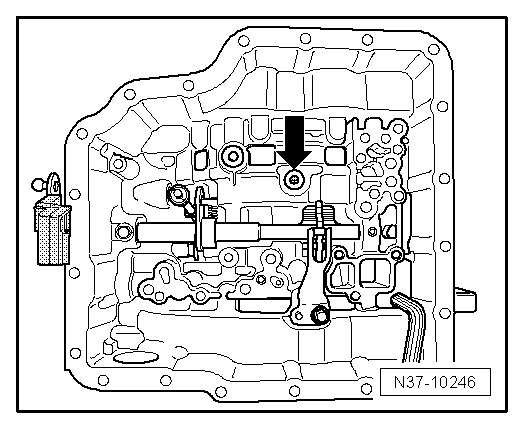

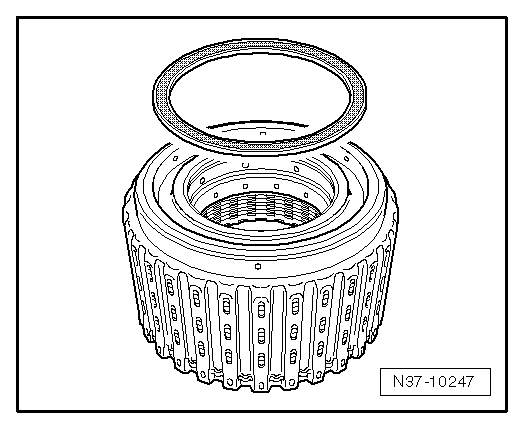

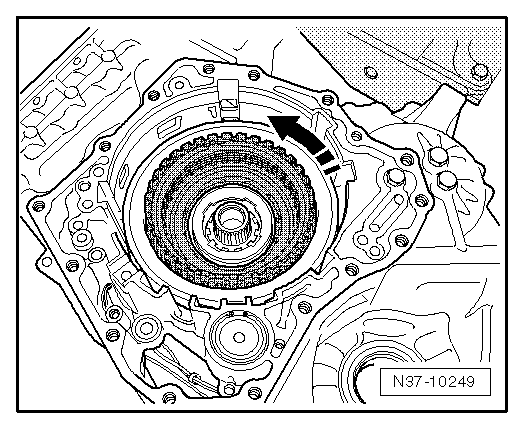

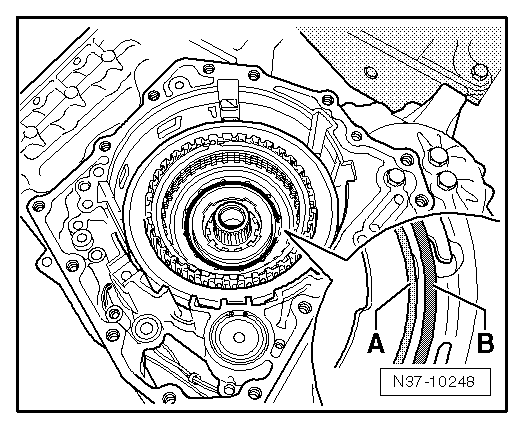

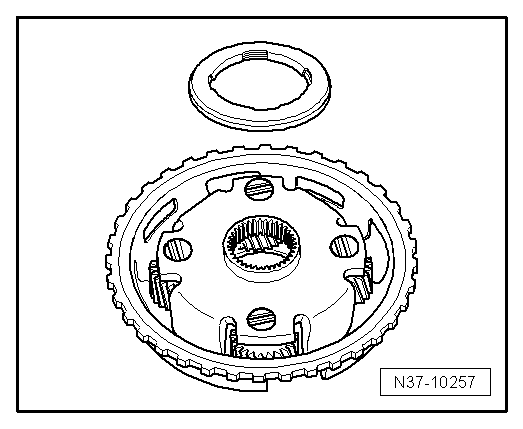

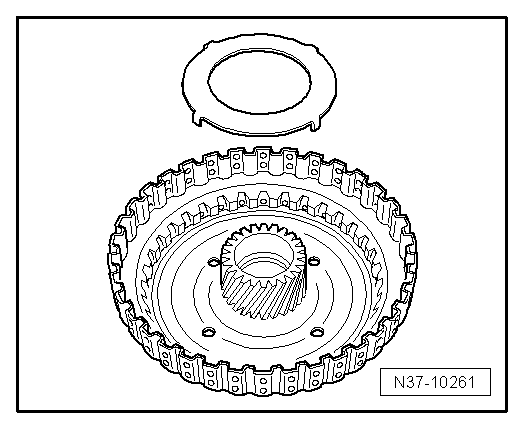

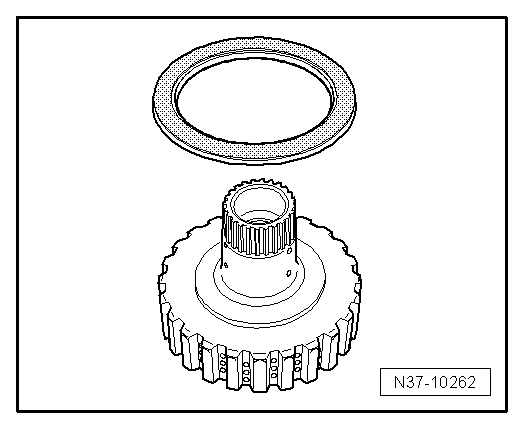

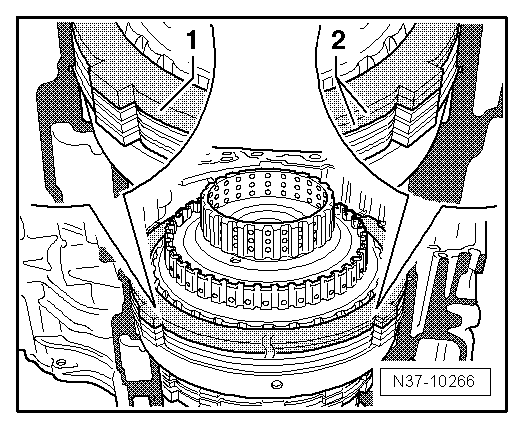

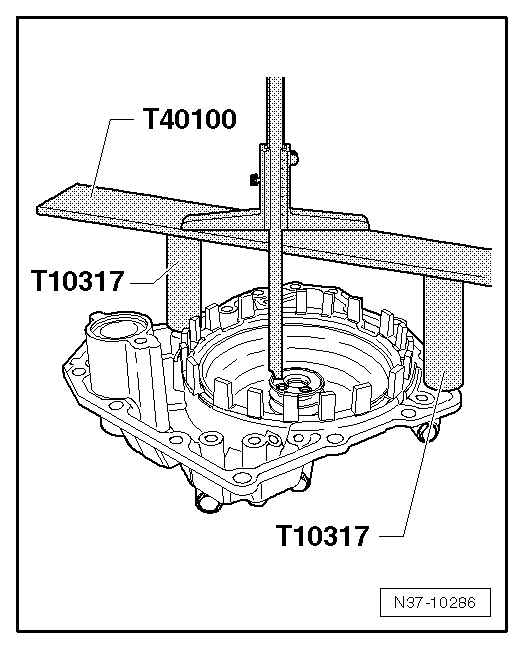

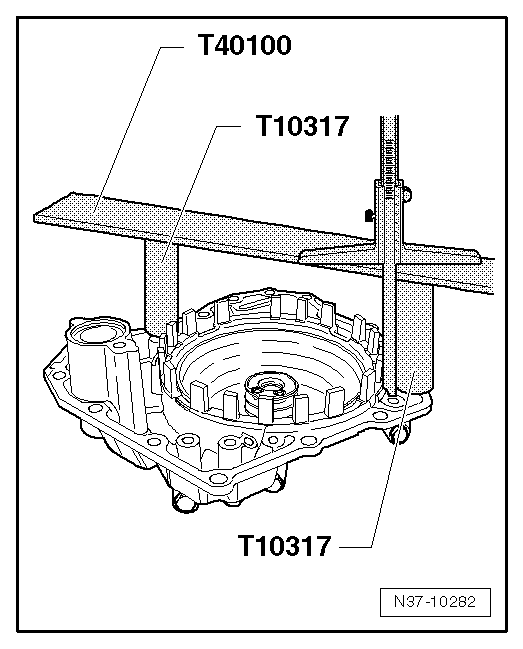

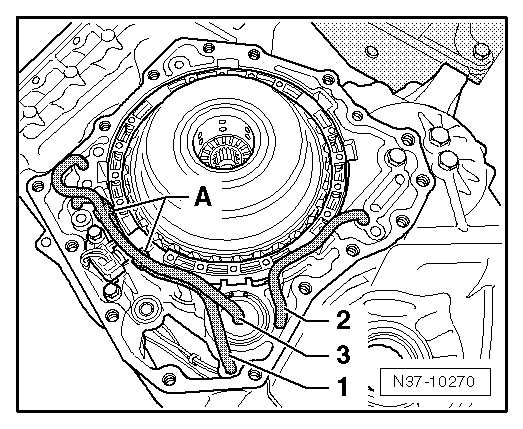

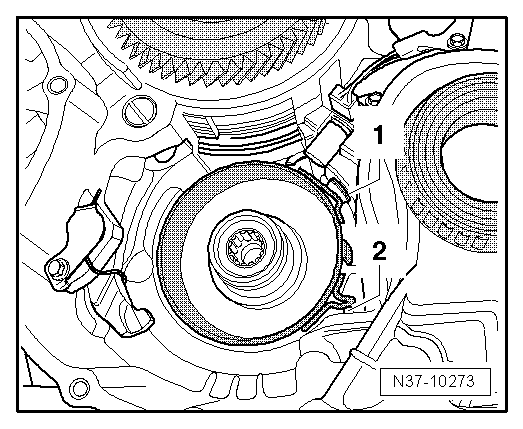

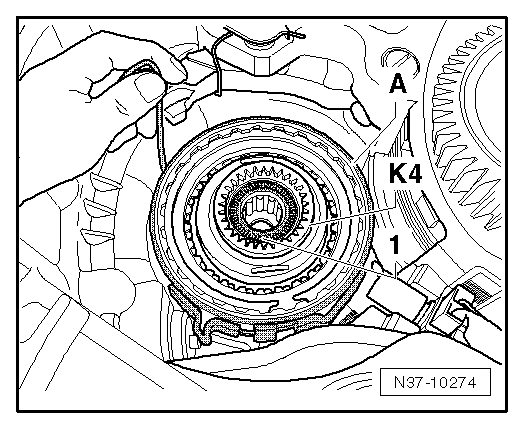

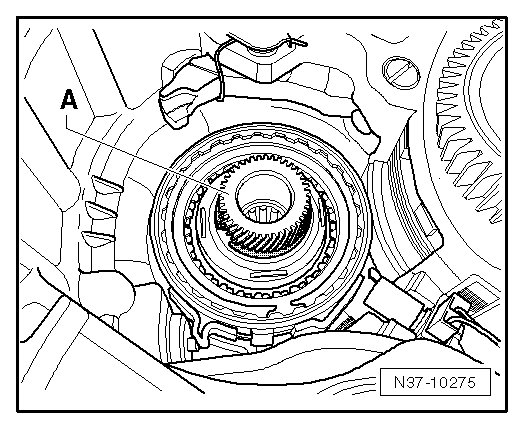

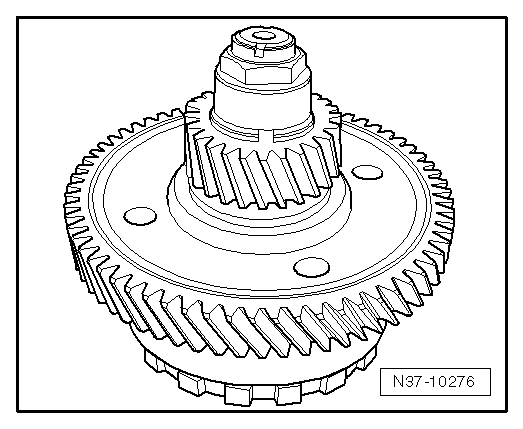

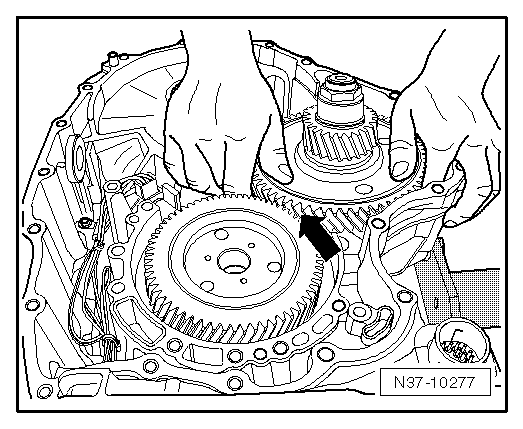

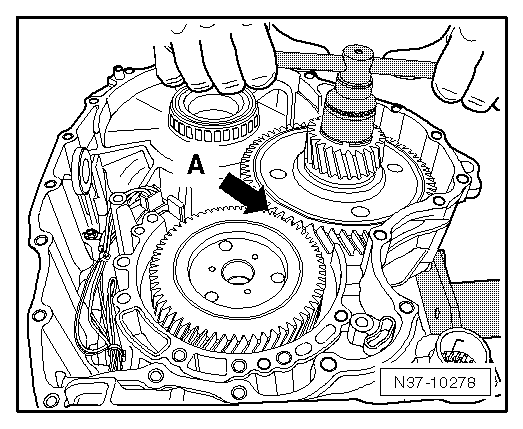

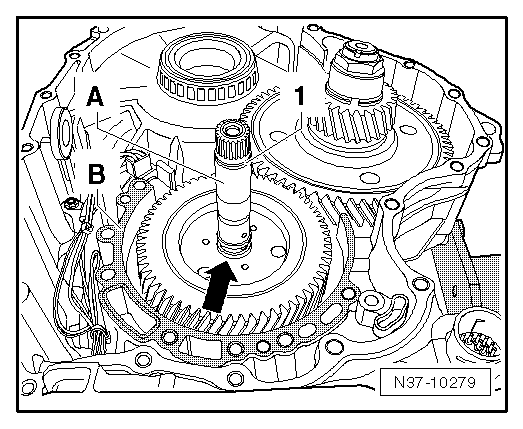

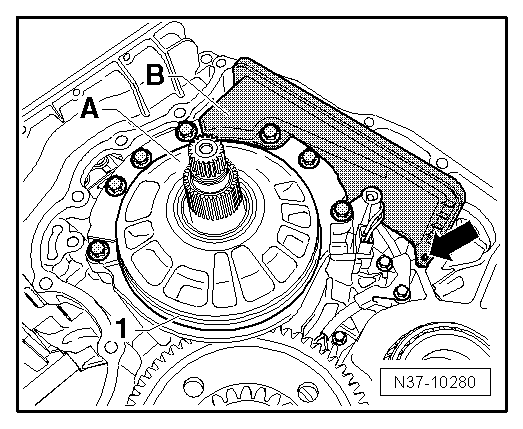

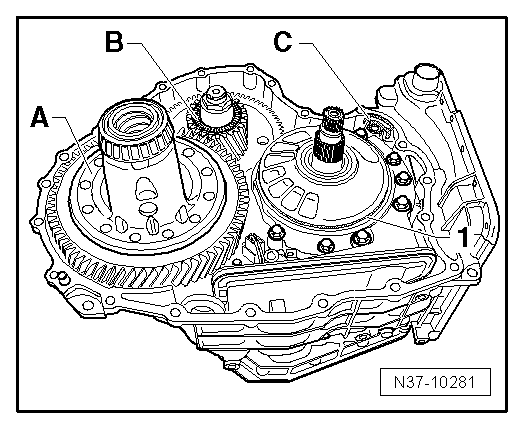

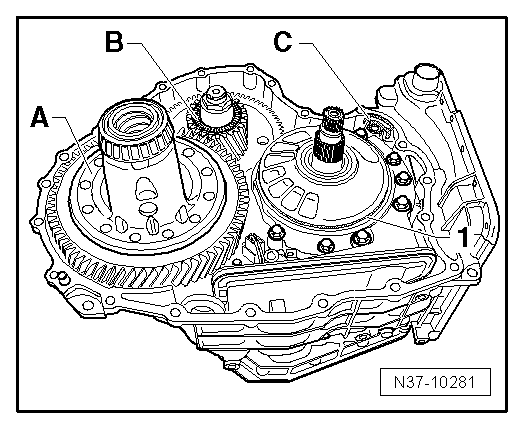

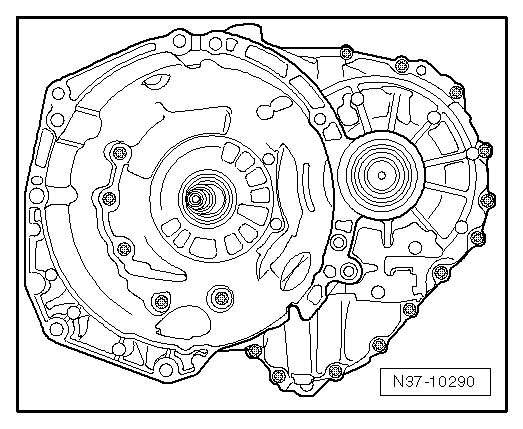

| Checking axial clearance of planetary gear set |

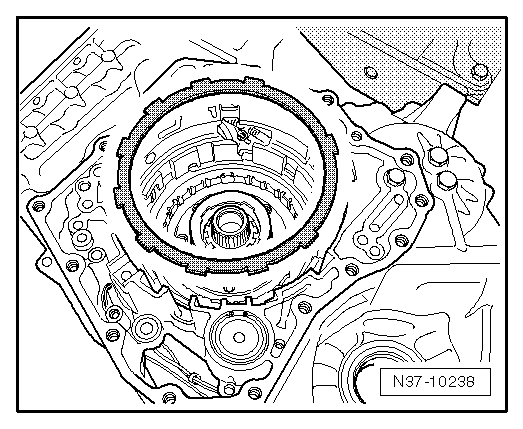

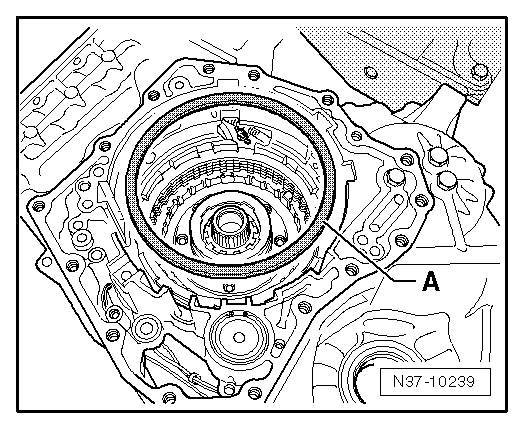

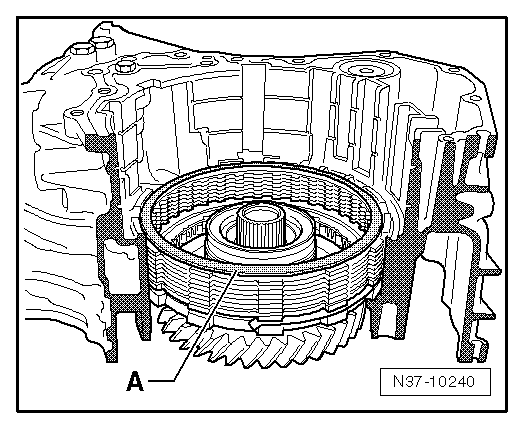

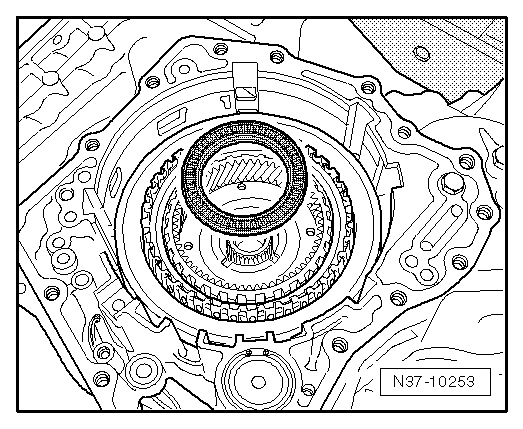

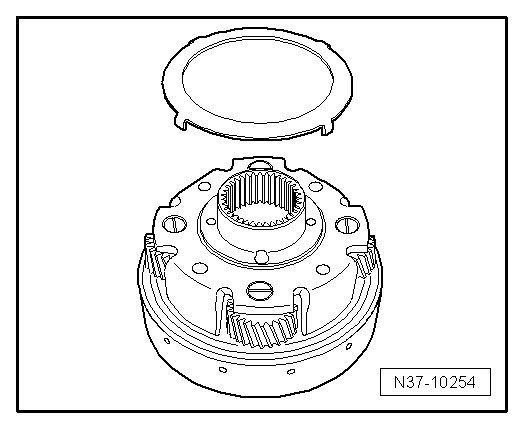

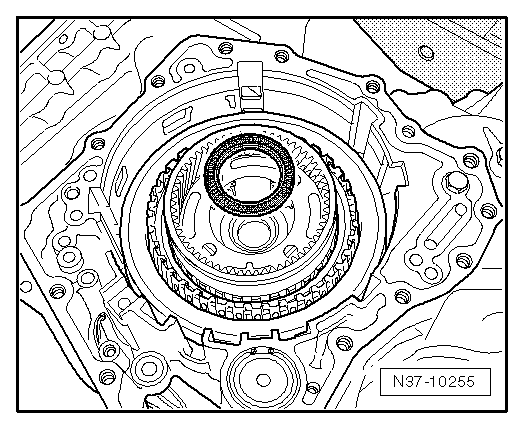

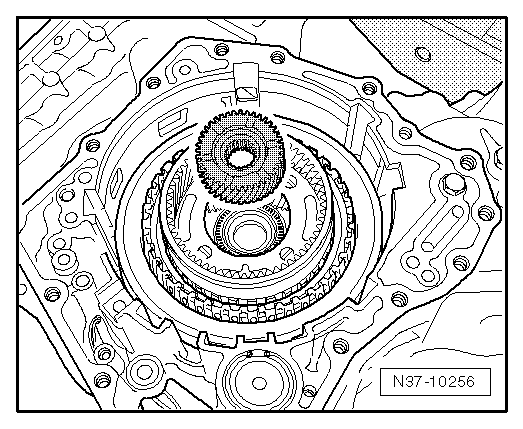

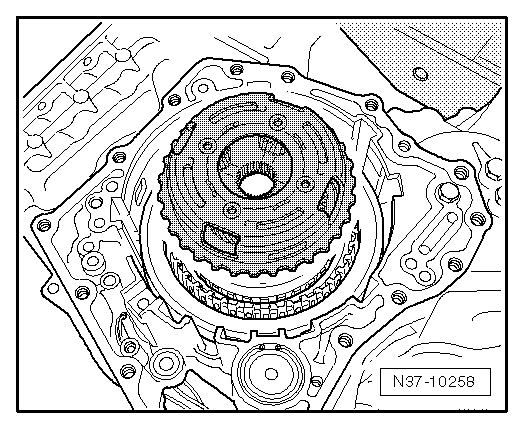

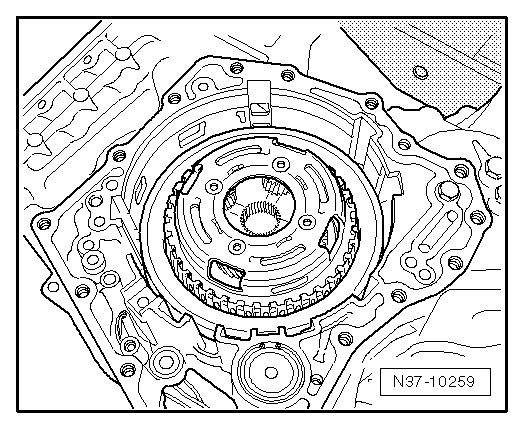

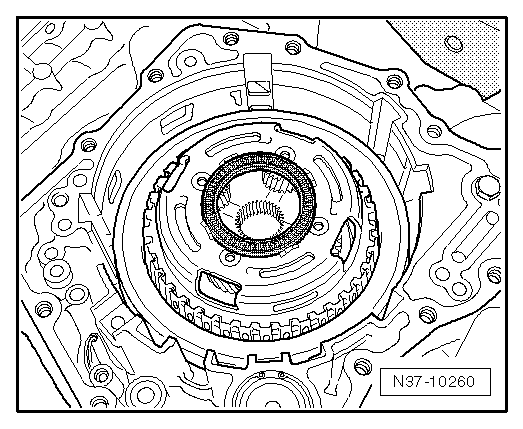

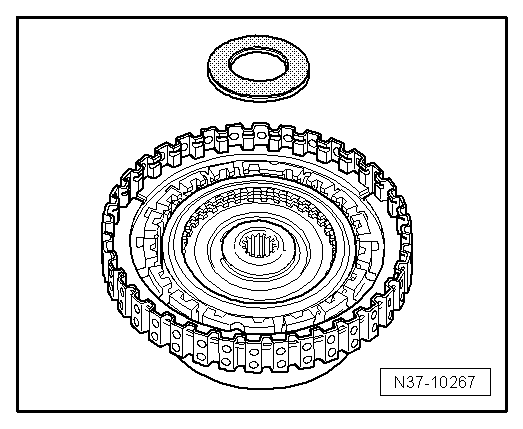

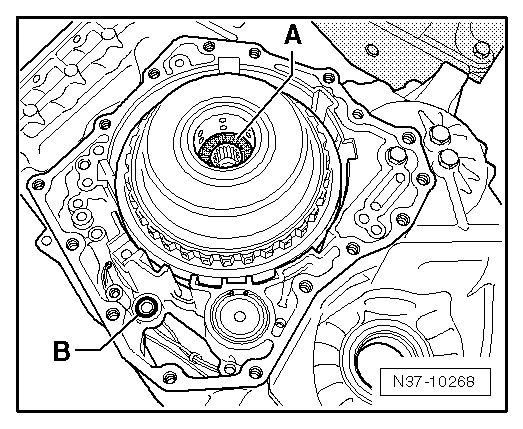

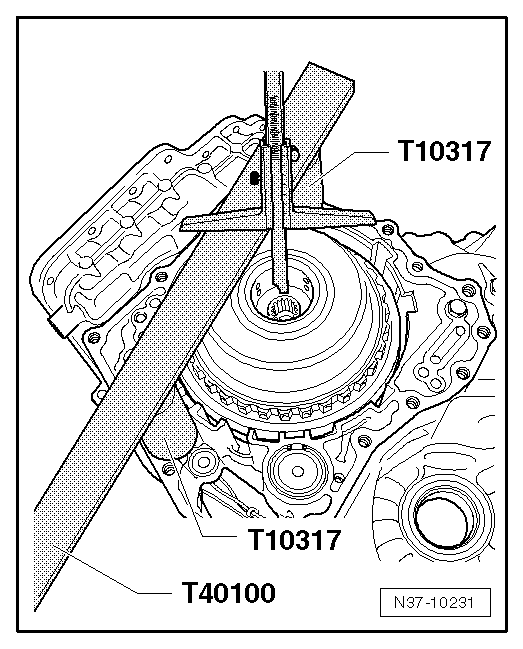

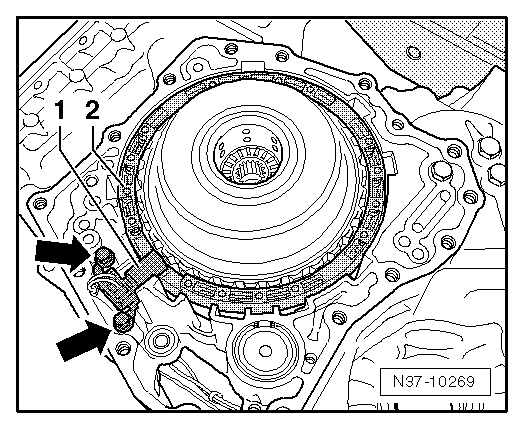

| The following measurements are required in order to check the axial clearance. Before taking these measurements it may be helpful to refer to this illustration, which shows where the axial clearance exists. |

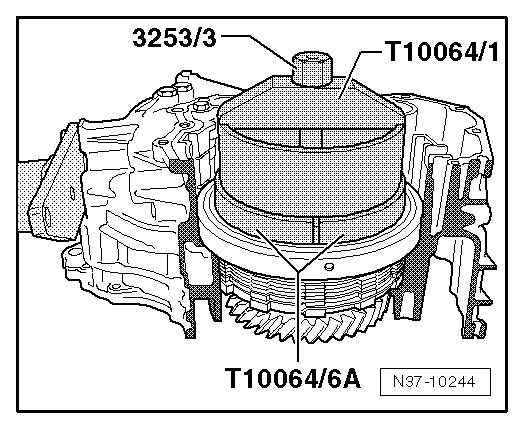

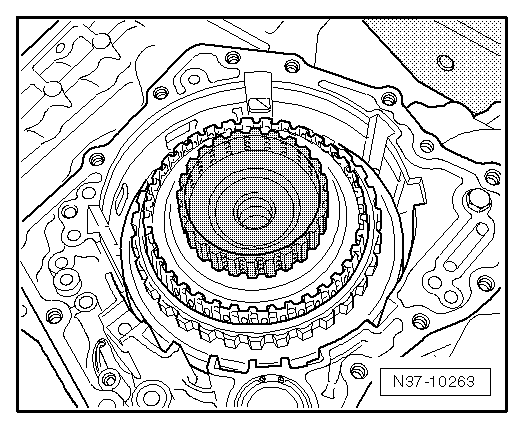

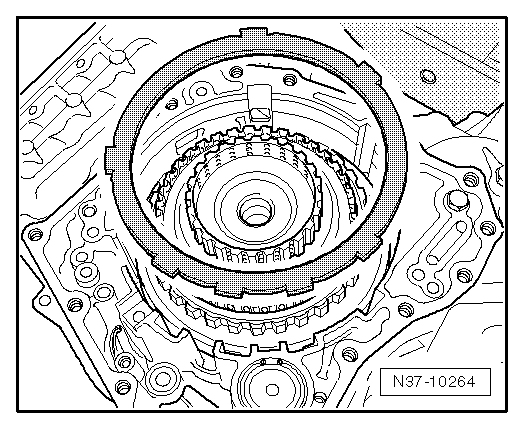

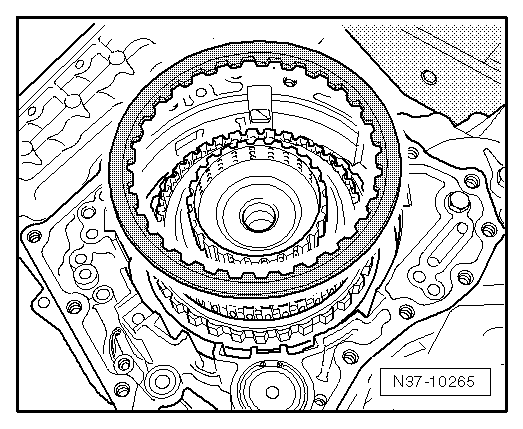

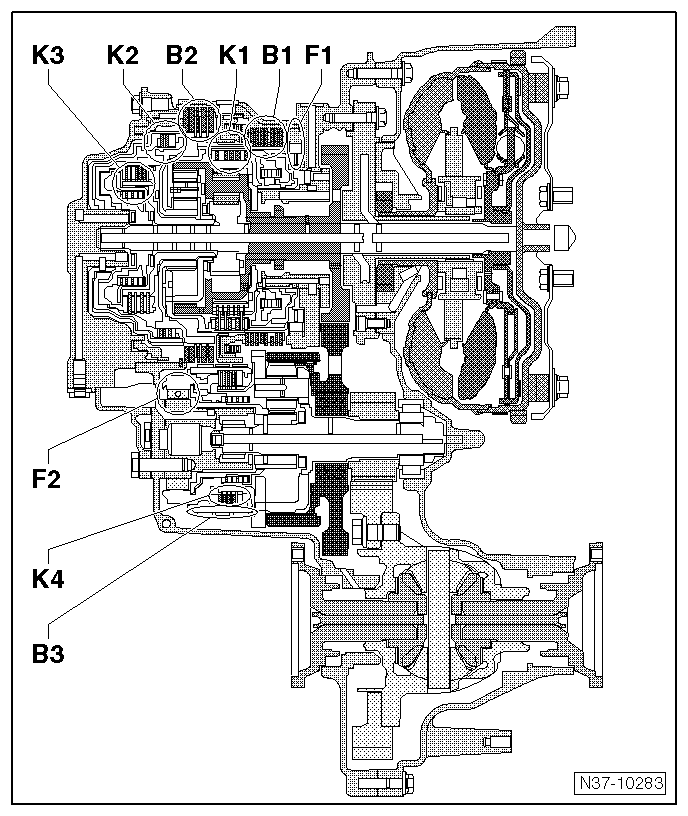

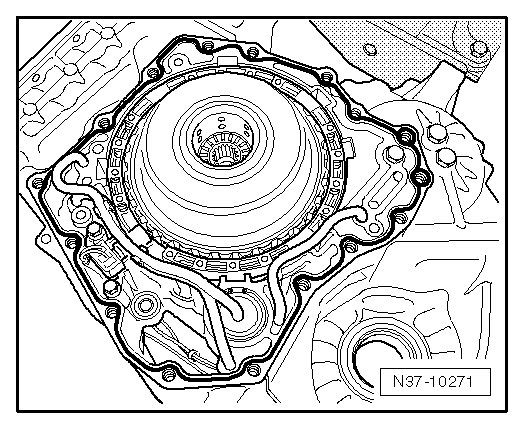

| This is an overall view of the gearbox. |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|