| –

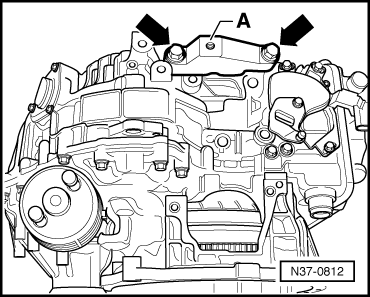

| Align engine/gearbox assembly in installation position. To do so, raise with support bracket -10 - 222 A- until gearbox bracket makes full contact with gearbox mounting. |

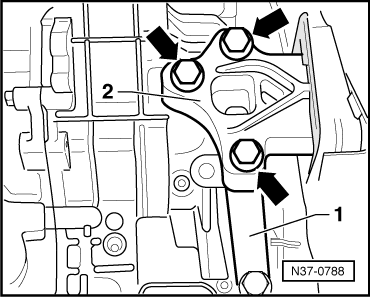

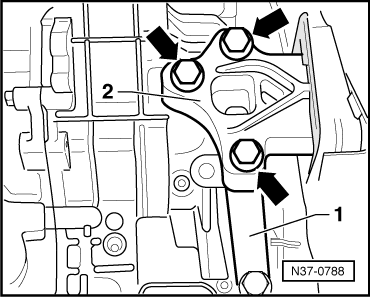

Caution | The threads in the gearbox bracket and in the gearbox can be damaged if the bolts are not inserted straight. |

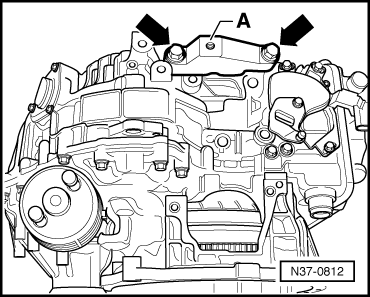

| Before fitting the bolts -arrows-, the gearbox bracket -1- and the gearbox mounting -2- must be aligned so they are parallel. If necessary, press gearbox up with engine and gearbox jack. |

|

| –

| Bolt gearbox mounting to gearbox bracket → Chapter. |

WARNING | Do not remove support bracket -10 - 222 A- until all bolts securing the left-hand engine/gearbox mounting have been tightened to the specified torque. |

|

| –

| Renew securing clip on support bracket for selector lever cable. |

| –

| Check selector lever cable setting and adjust if necessary → Chapter. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gear oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques is ± 15%. |

|

|

|

Note

Note

Note

Note

WARNING

WARNING Caution

Caution