A3 Mk1

|

Adjusting engine mountings

Adjusting engine mountings

|

|

|

|

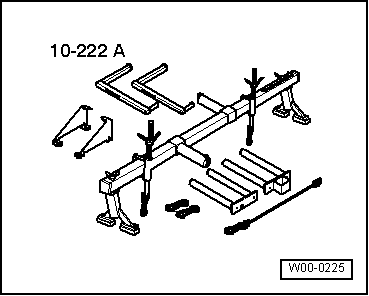

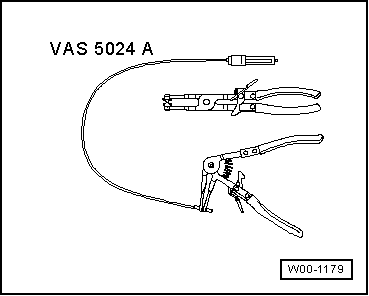

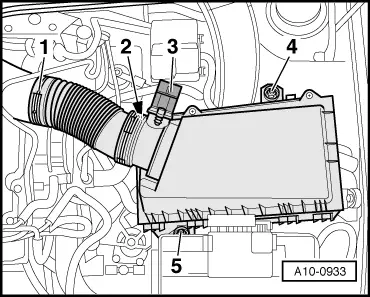

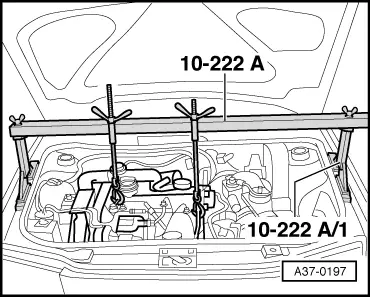

Special tools and workshop equipment required

|

|

|

|

|

|

|

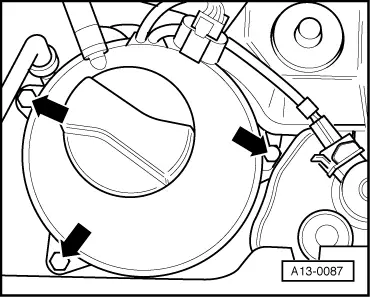

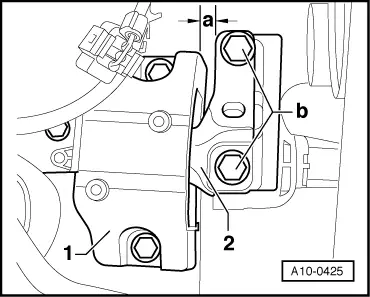

Check adjustment

|

|

|

|

|

|

|

|

|

|

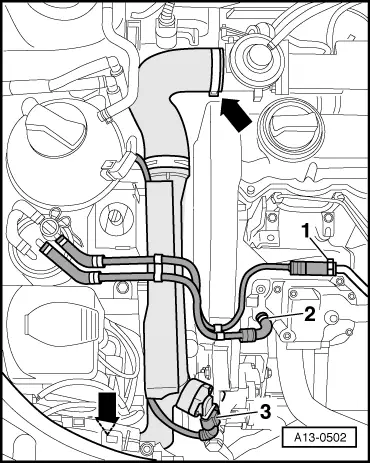

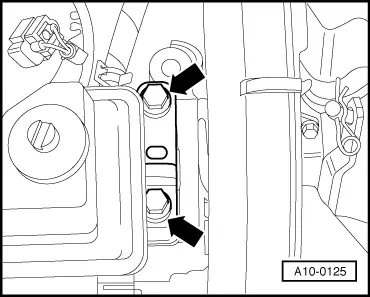

Adjusting If the distance measured is too small or too large, proceed as follows:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The remaining installation steps are carried out in the reverse sequence: |