A3 Mk1

|

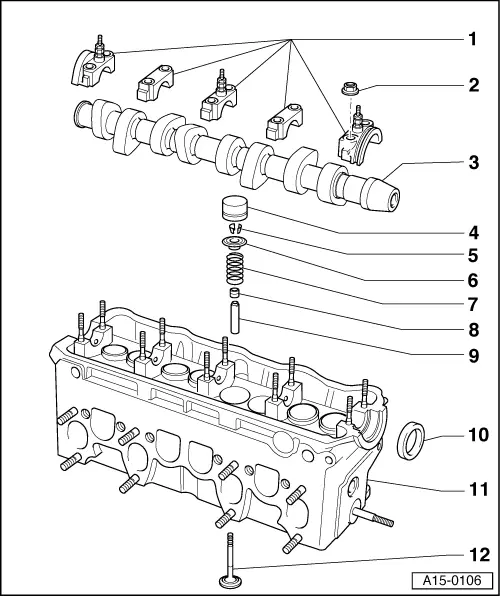

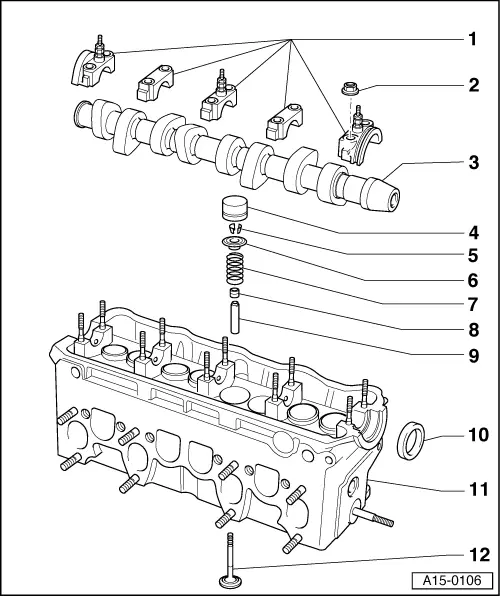

Servicing valve gear

Different valve gear designs

As of engine No. AGR 044 442 or AHF 006 066, respectively as well as for all ALH and ASV engines, a "light valve gear" is used in place of the "old valve gear". Identification characteristics for the "light valve gear":

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

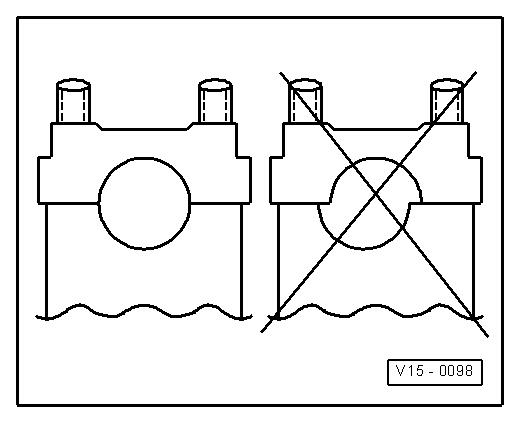

→ Fig. 1 Location of camshaft bearing cap Note offset. Before installing camshaft fit bearing caps and determine installation position. |

|

|||||||||||||||||||||

|

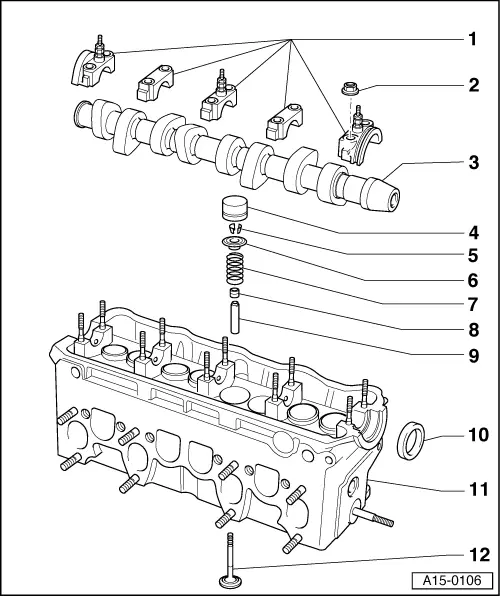

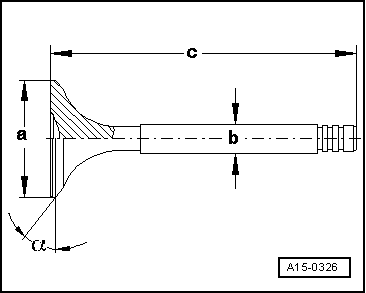

→ Fig.3 Valve dimensions Note: Valves must not be reworked. Only grinding in is permitted.

| |||||||||||||||||||||