| Vehicles with automatic gearbox: |

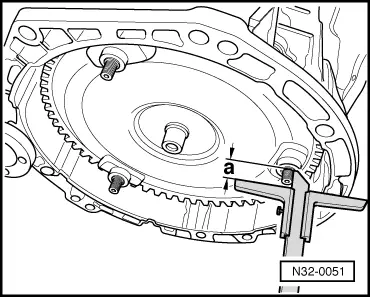

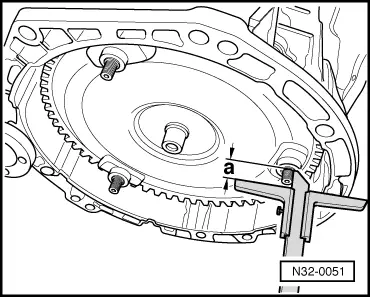

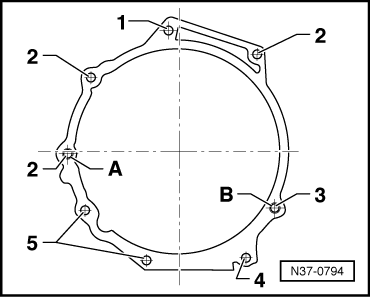

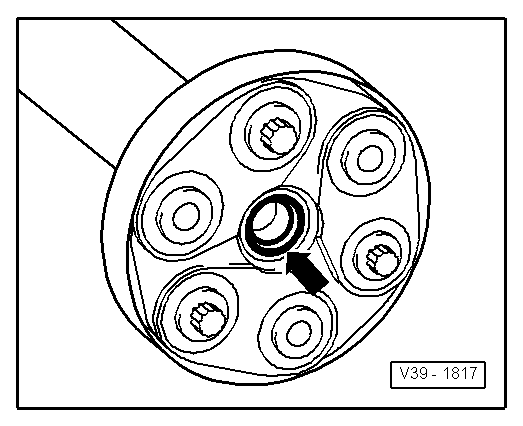

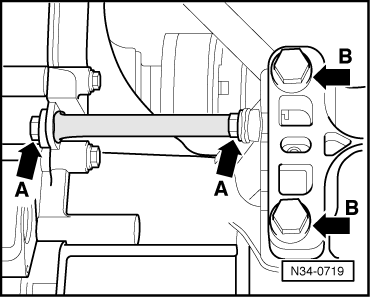

| If the torque converter is correctly installed, the depth -a- between the contact surfaces at the bottom of the studs on the torque converter and the contact surface of the torque converter bell housing is about 22 mm. |

| If the torque converter has not been completely inserted, this distance will be approx. 10 mm. |

Caution | If the torque converter is not installed correctly, the drive lugs of the torque converter and the ATF pump will be seriously damaged when the gearbox is joined to the engine. |

|

| –

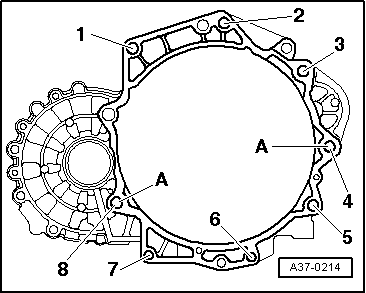

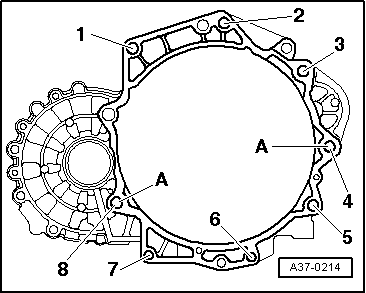

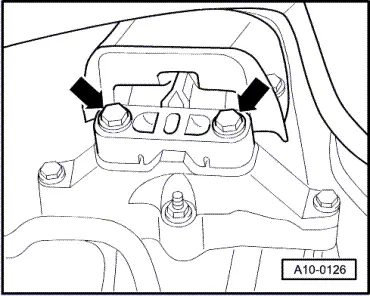

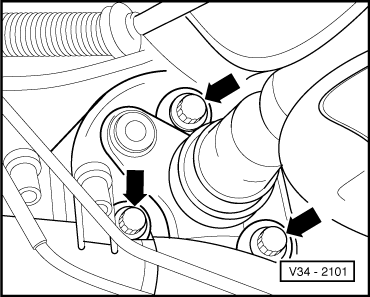

| To secure torque converter on drive plate, use only genuine nuts (same as original equipment) as specified in → Parts catalogue. |

| –

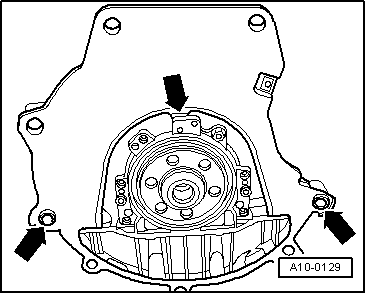

| Before installing engine, rotate torque converter and drive plate so that one hole and one stud are level with the aperture for the starter motor. |

| –

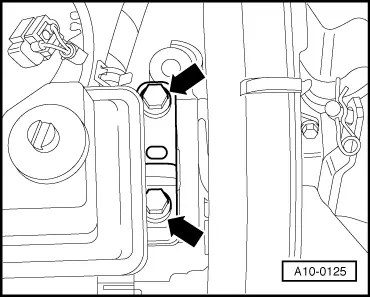

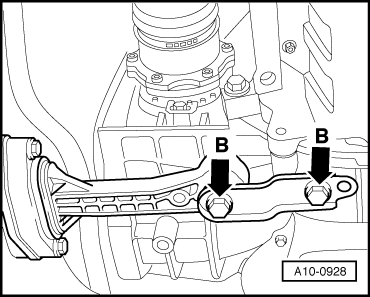

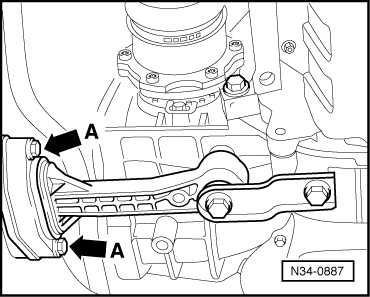

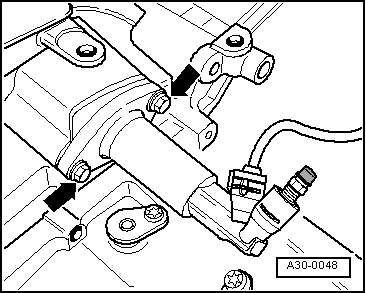

| Bolt gearbox to engine. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING