A3 Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm | |||||

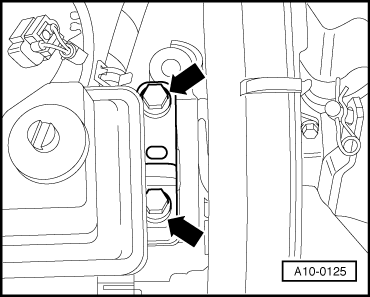

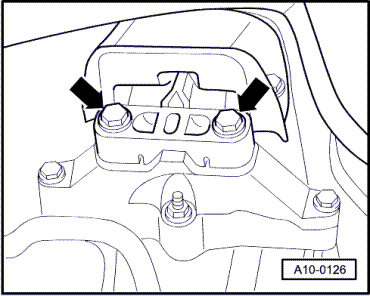

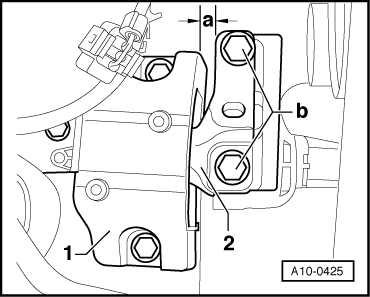

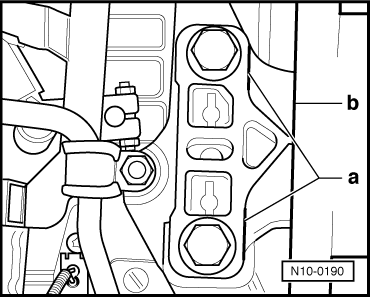

| Support arm to: | Gearbox support | 60 + 90° 1)2) | ||||

| Engine support | 60 + 90° 1)2) | |||||

| ||||||