A3 Mk1

|

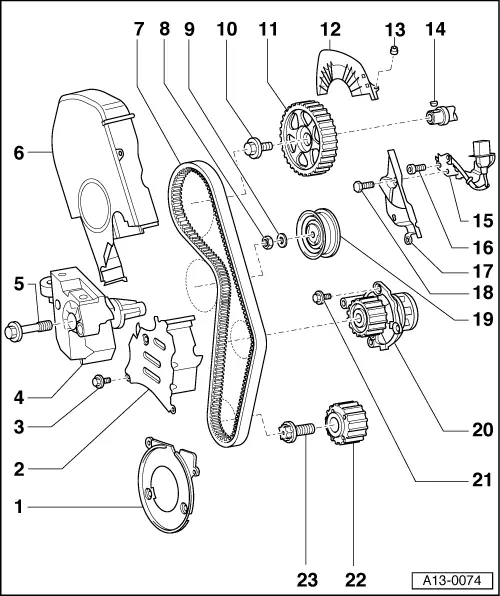

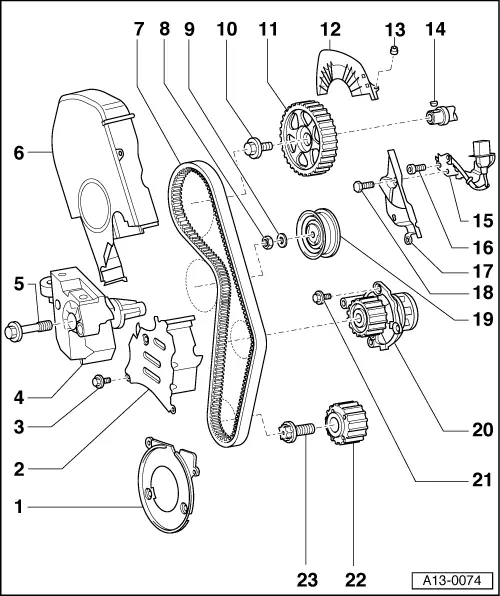

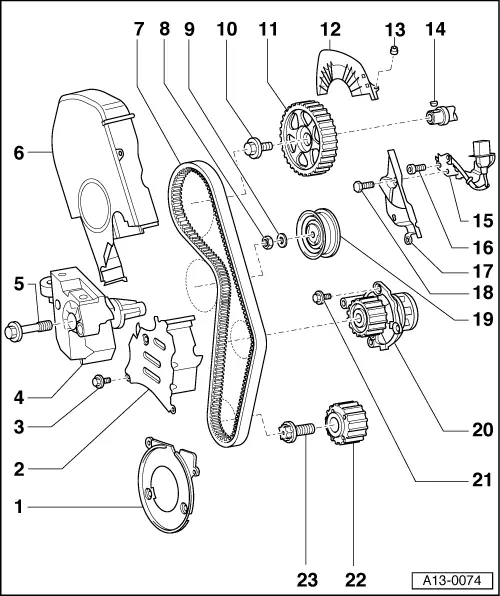

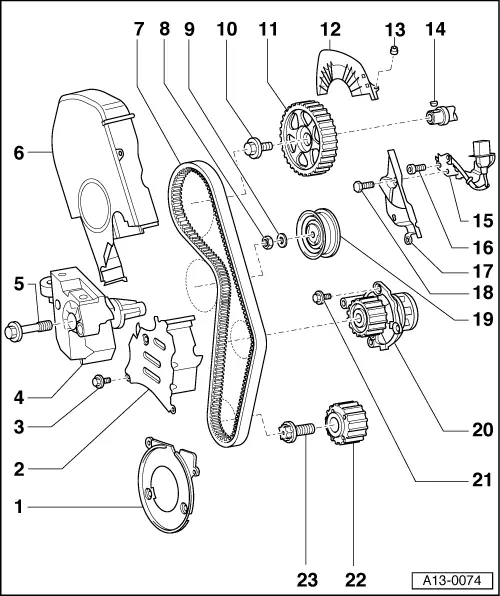

Dismantling and assembling engine

Removing and installing toothed belt

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

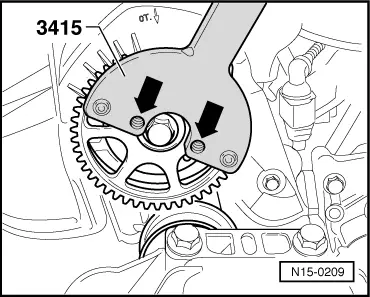

→ Fig.1 Detaching camshaft sprocket

Note: Remove the bolts from the threaded bores -arrows- before applying counterhold 3415. |

|

|

|

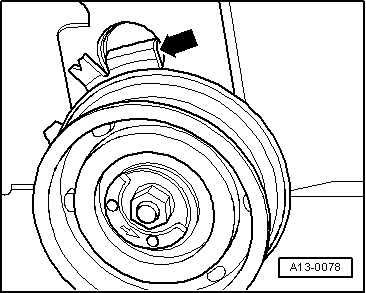

→ Fig.2 Installation position of semi-automatic tensioning roller Retaining lug -arrow- must engage in slot on cylinder head. |

|

|

|

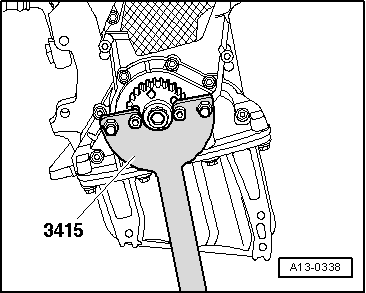

→ Fig.3 Removing and installing crankshaft sprocket

|

|

|

|

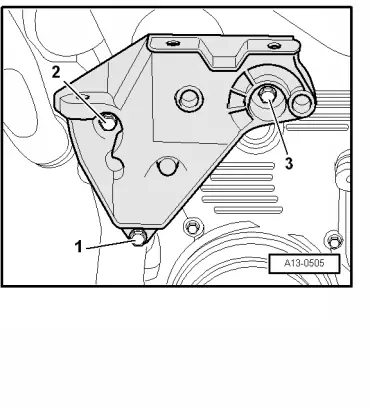

→ Fig.4 Installing engine support

|