A3 Mk1

|

|

|

|

|

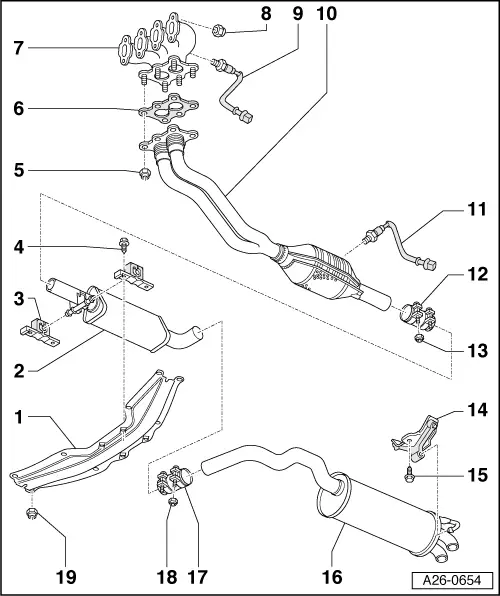

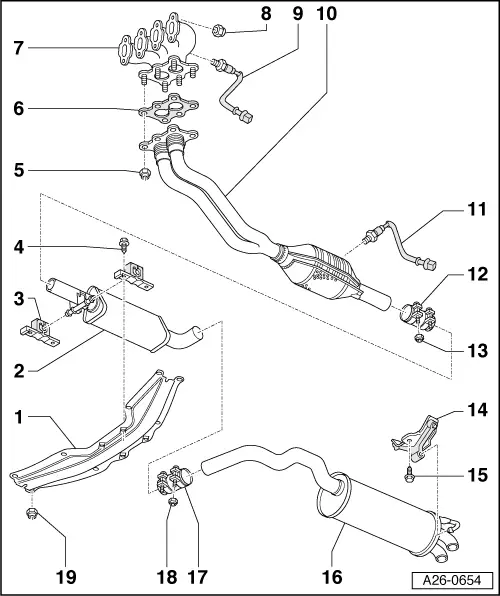

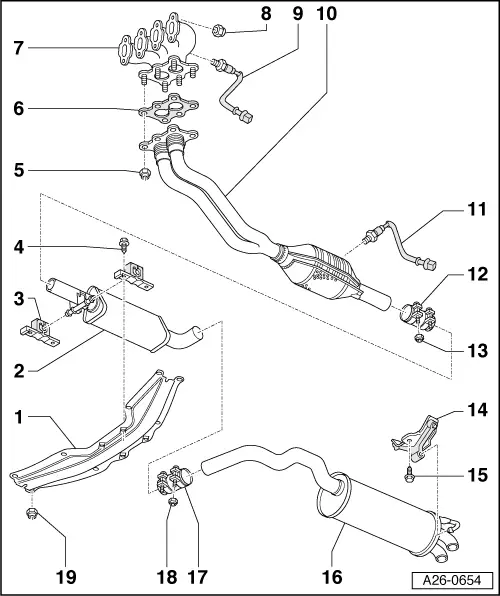

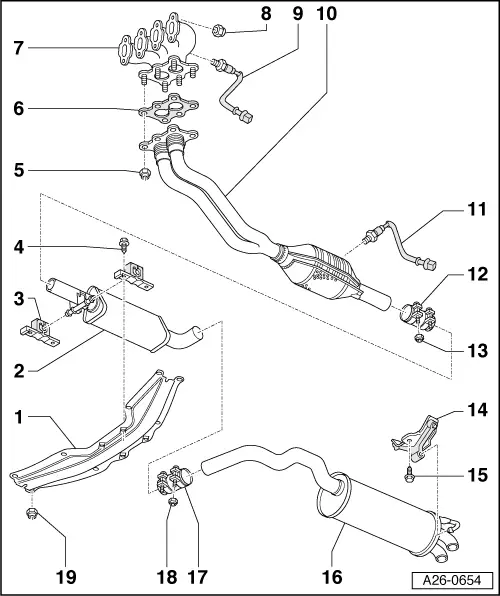

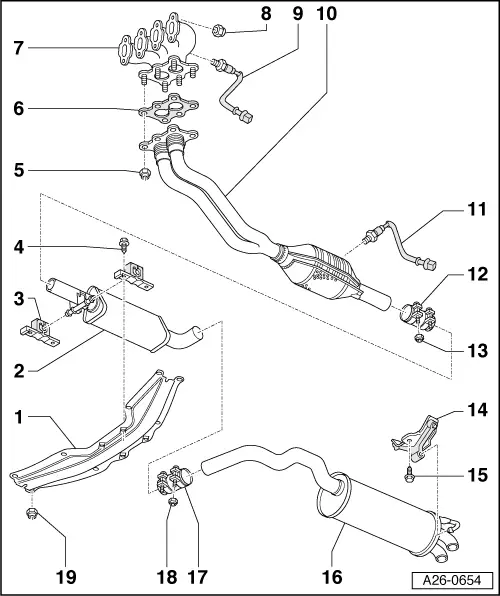

=> Parts List

|

|

|

=> Parts List

=> Simos Fuel Injection and Ignition System; Repair group 24

|

|

|

=> Parts List

=> Simos Fuel Injection and Ignition System; Repair group 24

|

|

|

|

|

|

|

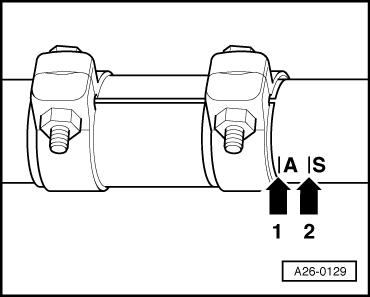

→ Fig.1 Installation position of front clamp

|

|

|

|

|

|

|

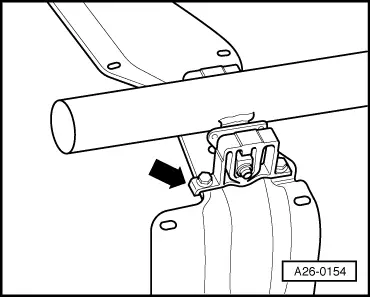

→ Fig. 3 Installation position of mounting Angled end at base of mounting -arrow- faces in direction of travel. |