A3 Mk1

| Removing and installing toothed belt |

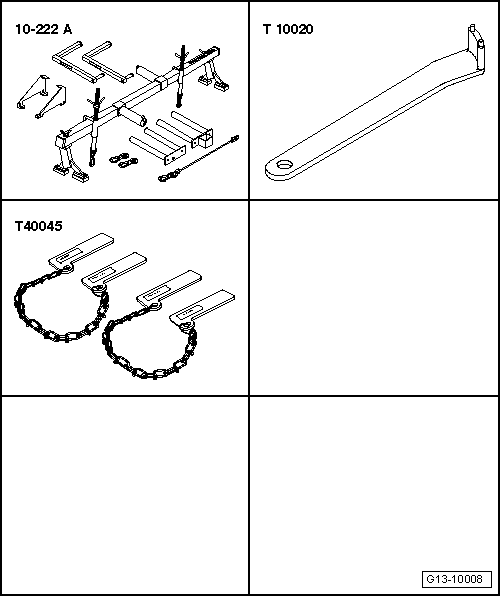

| Special tools and workshop equipment required |

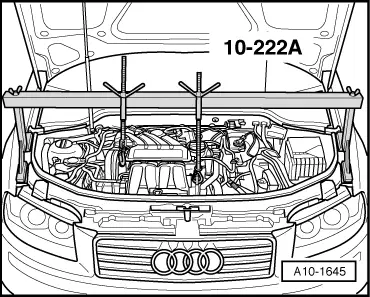

| t | Support bracket -10-222 A- |

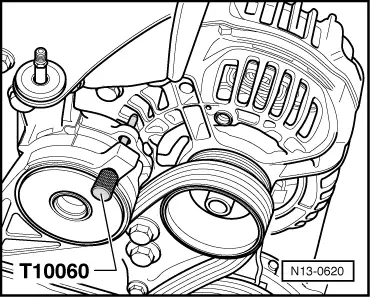

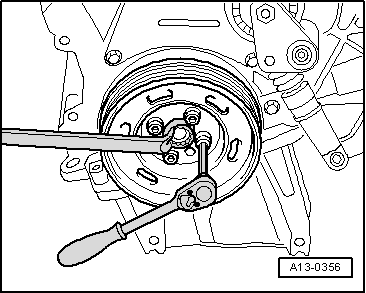

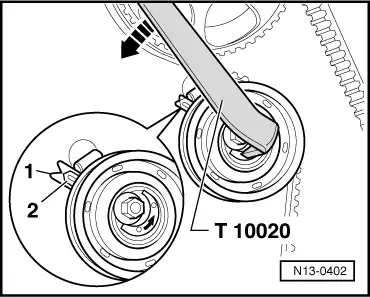

| t | 2-hole pin wrench -T10020- |

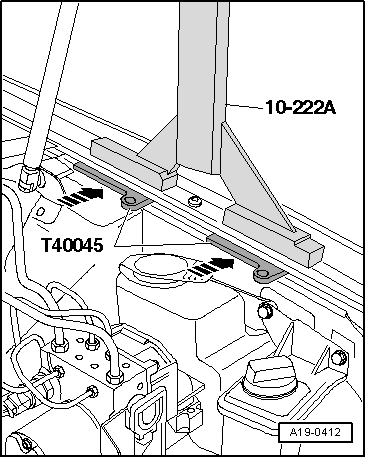

| t | Mud wing compensation plate -T40045- |

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm | ||||||

| Toothed belt tensioning roller to cylinder head | 23 | ||||||

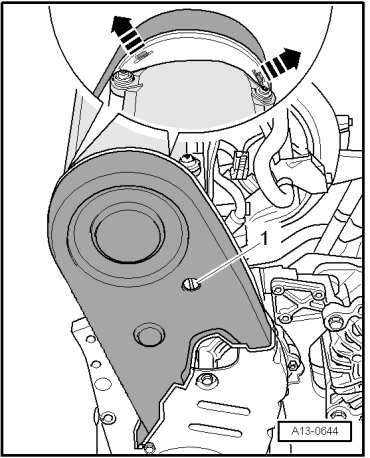

| Toothed belt cover (bottom) to cylinder block | 10 1) | ||||||

| Toothed belt cover (centre) to cylinder block | 10 1) | ||||||

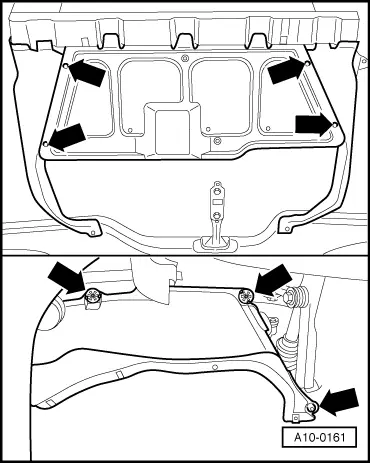

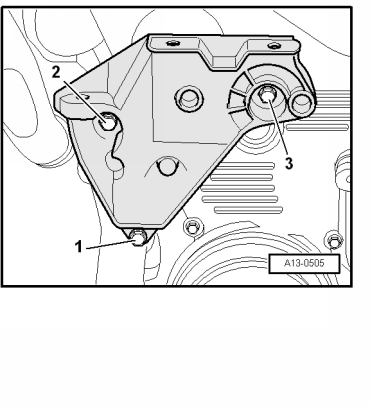

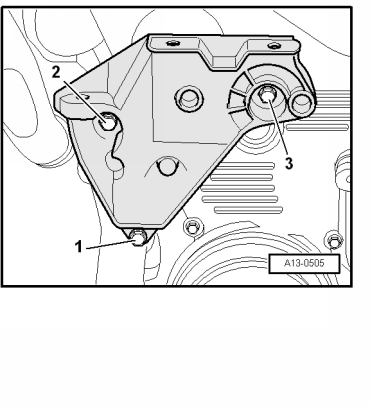

| Engine support to cylinder block | 45 | ||||||

| Engine mounting to body | 40 + 90° 2)3) | ||||||

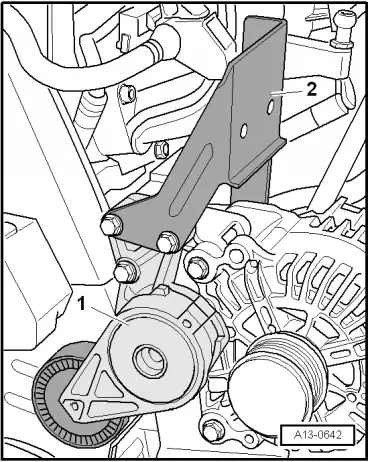

| Connecting bracket to body/engine mounting | 25 | ||||||

| Tensioner for poly V-belt to bracket for ancillaries | 23 | ||||||

| Splash plate to bracket for ancillaries | 23 | ||||||

| |||||||