A3 Mk1

|

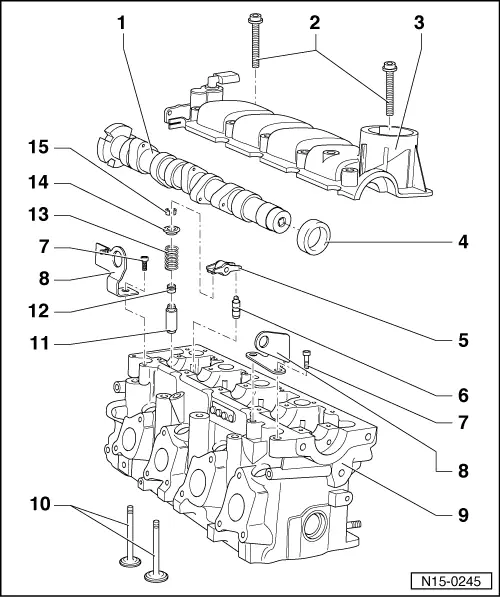

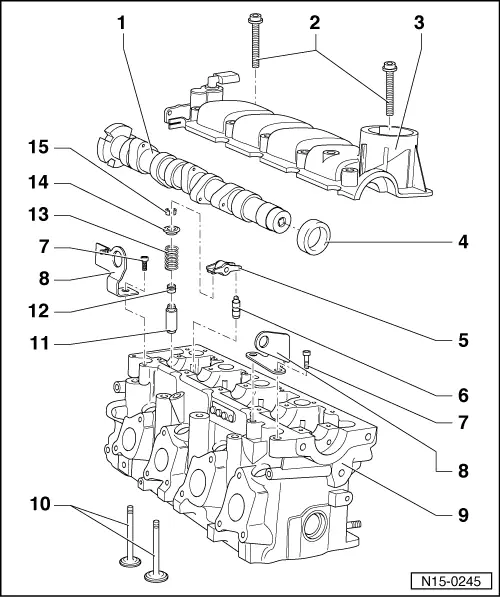

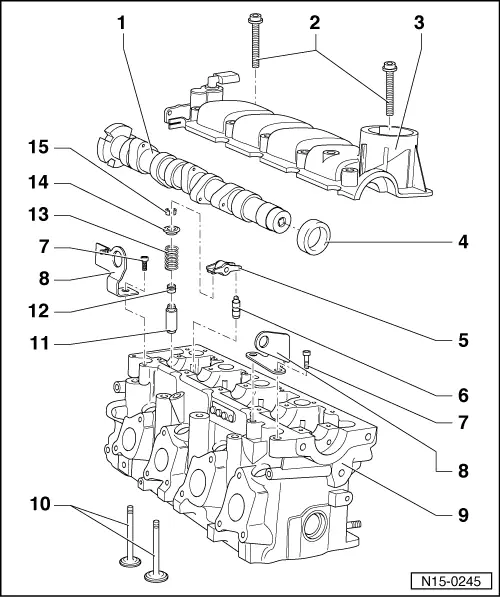

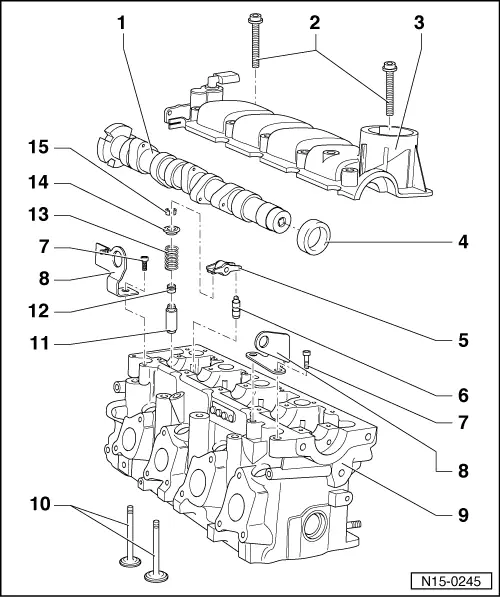

Servicing valve gear

Servicing valve gear

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

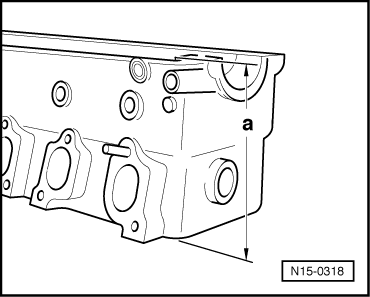

→ Fig. 1 Reworking cylinder head sealing surface, cylinder block side Cylinder head reworking dimension: Checking camshaft axial clearance |

|

|

|

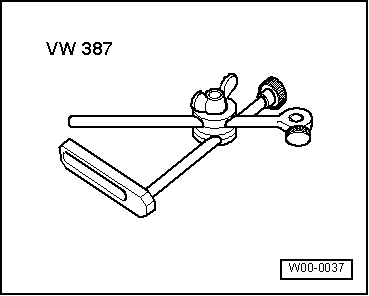

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

|

|

|

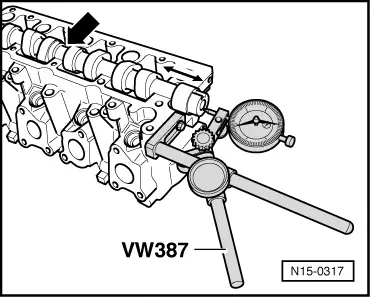

Check with support elements and cylinder head cover removed.

Wear limit: max. 0.15 mm |

|

|||||

|

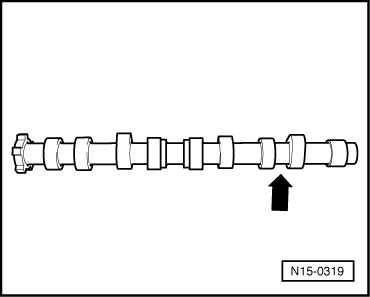

→ Fig.2 Camshaft identification

| |||||

|

|||||||||||||||||||||

|

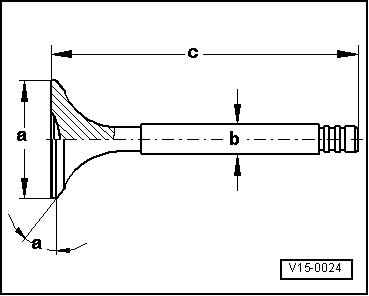

→ Fig. 3 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||