A3 Mk1

|

Adjusting engine mountings

Adjusting engine mountings

|

|

|

|

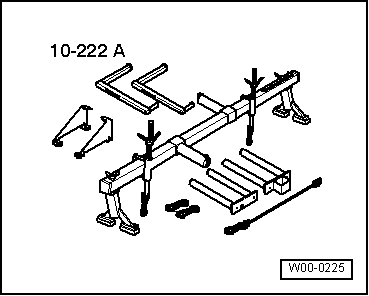

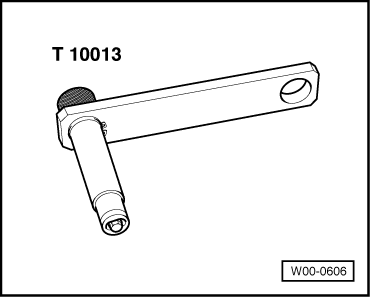

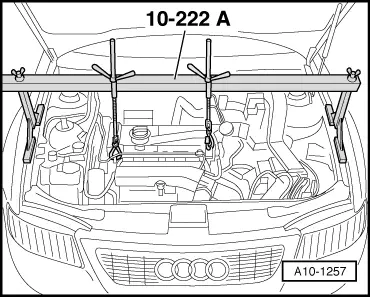

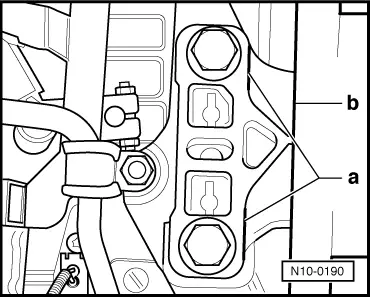

Special tools and workshop equipment required

|

|

|

|

|

|

|

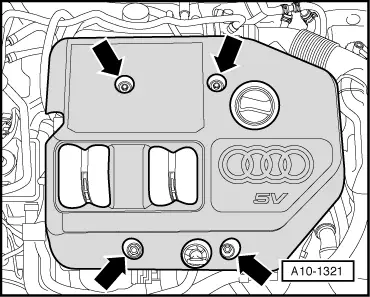

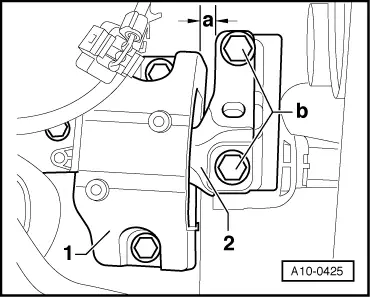

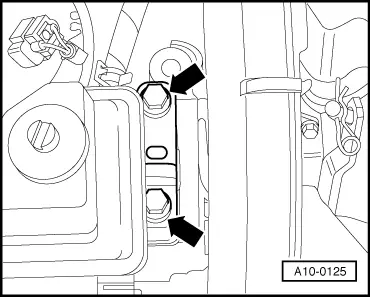

Checking adjustment

|

|

|

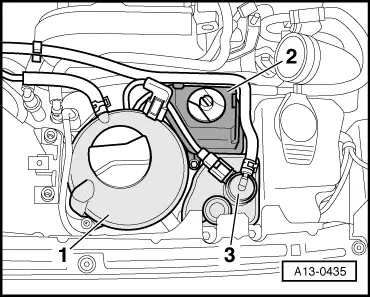

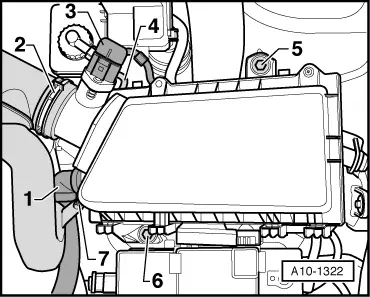

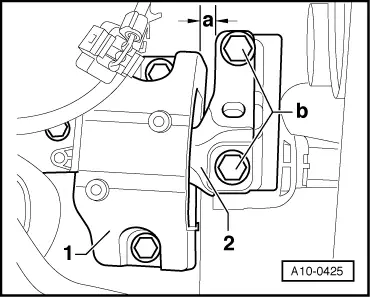

Note: The ACF container -3- does not have to be removed. |

|

|

|

|

|

|

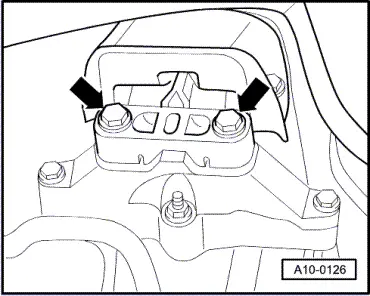

If the gap is too narrow or too wide, proceed as follows:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

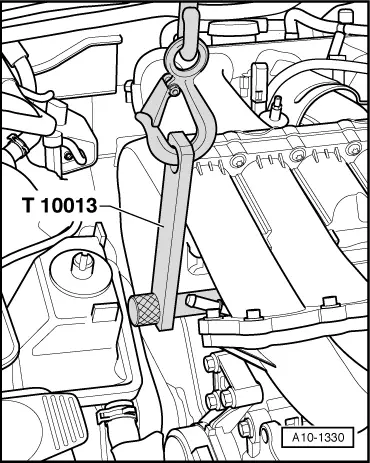

Install in reverse sequence; note the following points: Note: To remove the retainer T10013 the securing washer must be raised with a screwdriver. |