A3 Mk1

|

Removing and installing engine

Removing

Notes:

Caution!

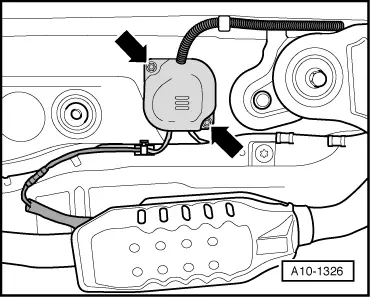

On vehicles equipped with telematics the telematics control unit must be switched to service mode before the battery terminals are disconnected.=>Radio, telephone and navigation system; Repair group 91

|

|

|

|

Warning!

Hot steam or hot coolant can escape when the cap on the expansion tank is opened. Cover the cap with a cloth, and open it carefully.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

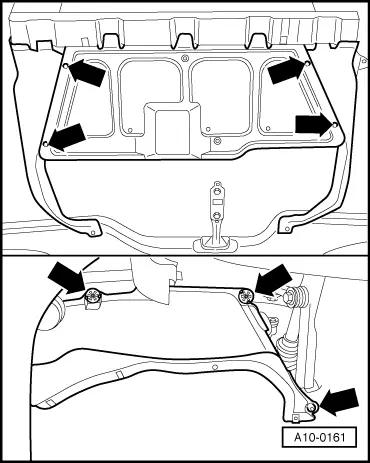

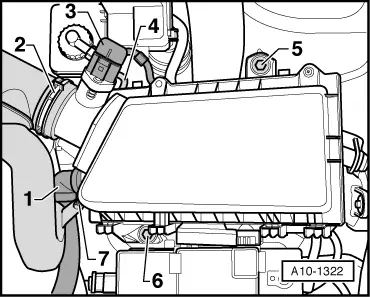

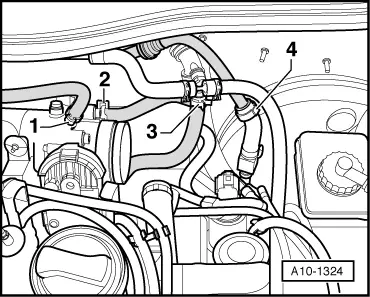

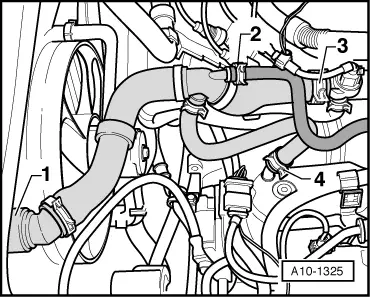

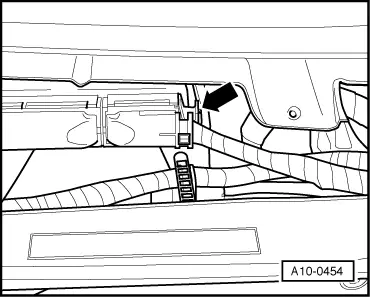

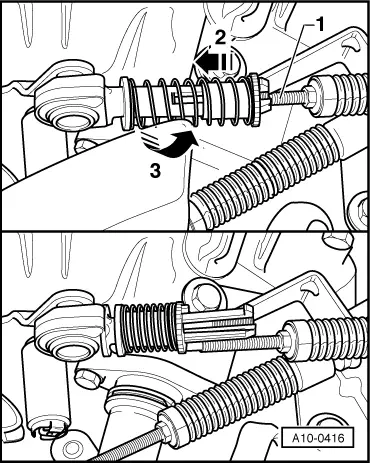

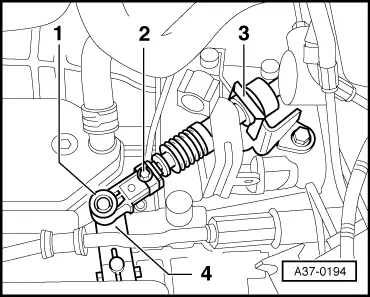

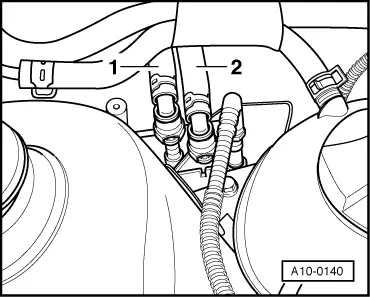

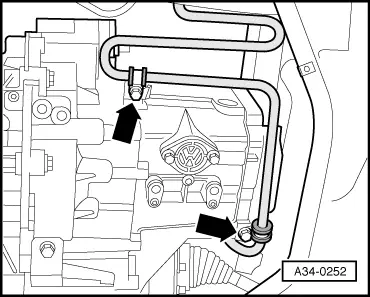

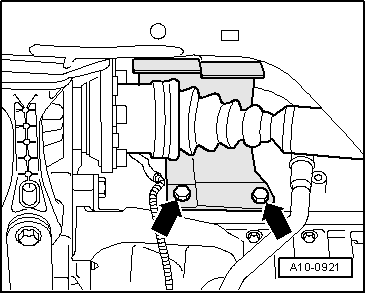

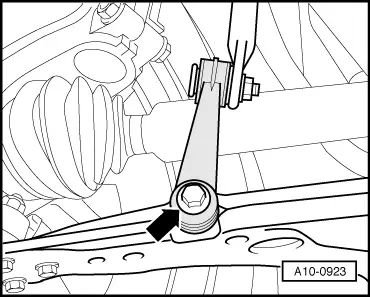

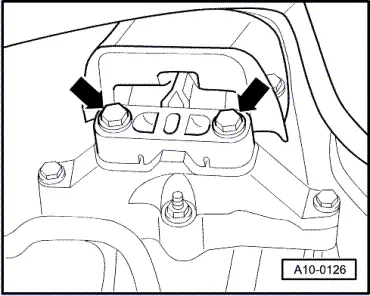

Note: In the picture shown on vehicle with automatic gearbox. |

|

|

|

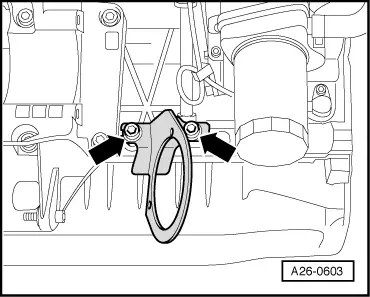

Vehicles with automatic gearbox

|

|

|

|

All models

Vehicles with manual gearbox:

|

|

|

|

All models

|

|

|

|

|

|

|

|

|

|

|

|

|

Vehicles with manual gearbox (until approx. 07/98):

|

|

|

|

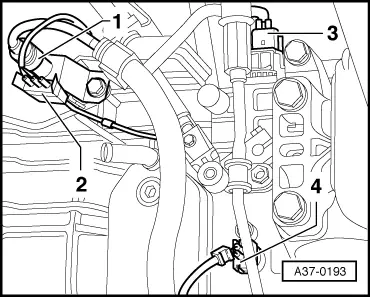

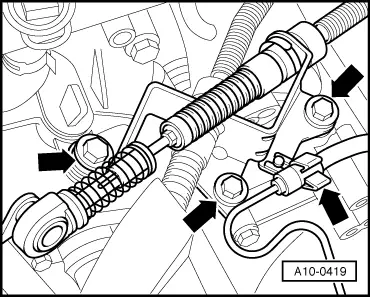

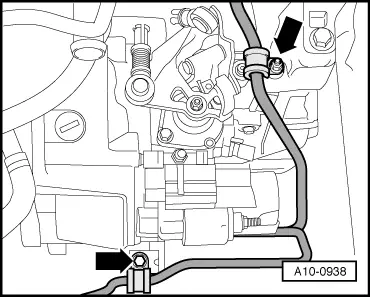

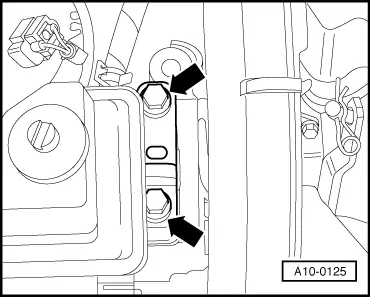

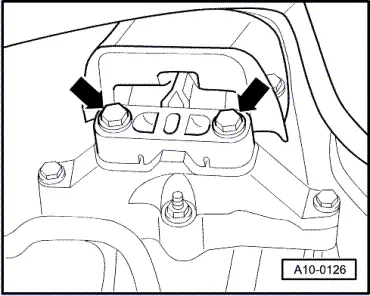

Vehicles with manual gearbox (from approx. 08/98): Disconnect both selector cables at gearbox as follows:

|

|

|

|

All vehicles with manual gearbox:

|

|

|

|

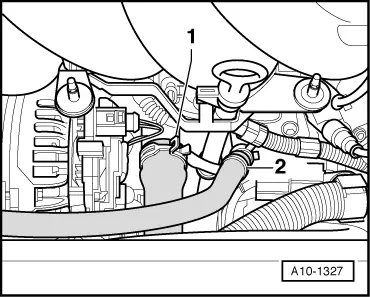

|

|

Note: Do not depress clutch pedal after removing slave cylinder. |

|

|

|

Vehicles with automatic gearbox

|

|

|

|

|

|

|

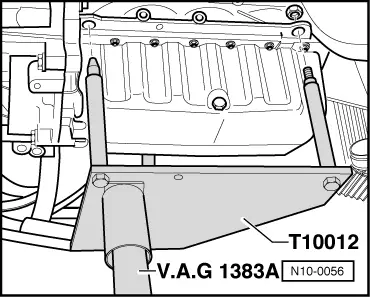

All models

|

|

|

|

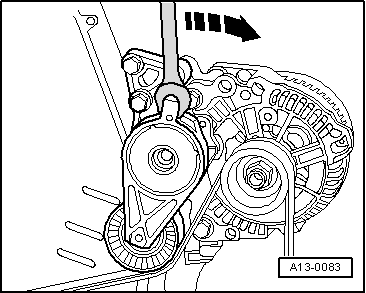

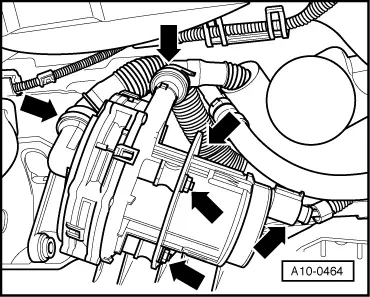

Note: Before removing the ribbed belt, mark the direction of rotation with chalk or a felt pen. If a used belt rotates in the wrong direction when refitted, it can break.

|

|

|

|

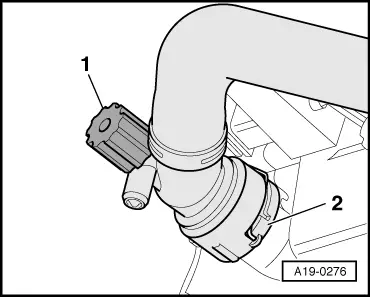

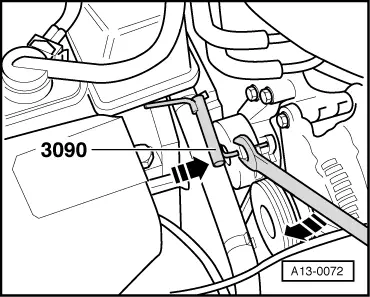

Note: → The tensioning element must be secured with a suitable pin or mandrel of4.5 mm dia. and about 55 mm long. On vehicles without headlight washer system conrod support 3090 may also be used. |

|

|

|

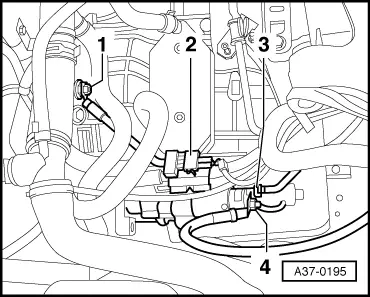

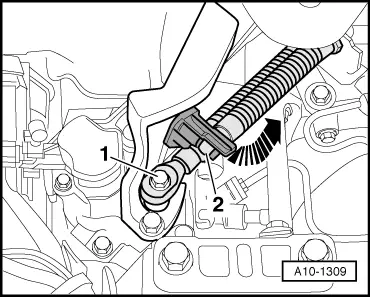

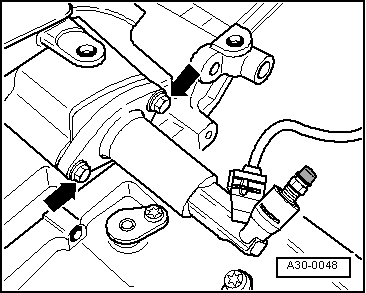

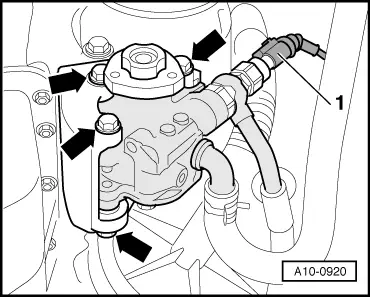

Warning

Fuel system is under pressure. Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection.

|

|

|

|

|

|

|

|

|

|

|

|

|

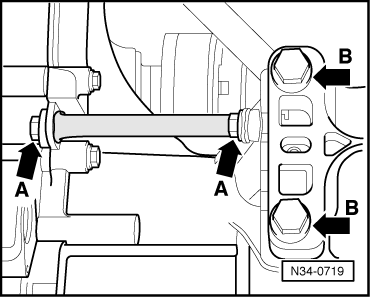

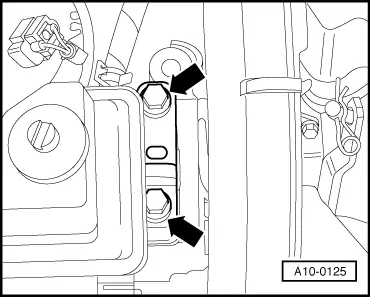

Vehicles with manual gearbox

|

|

|

|

All models

|

|

|

|

|

|

|

|

|

|

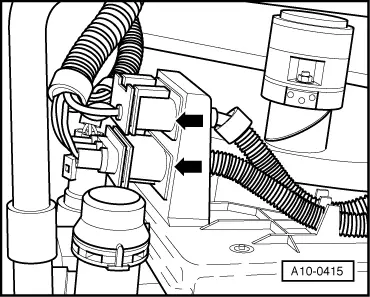

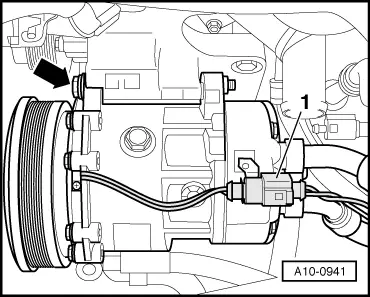

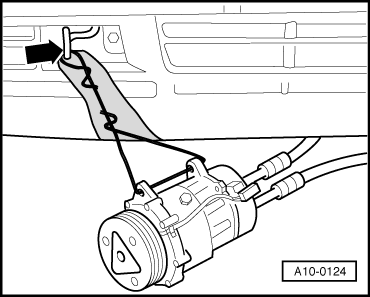

Vehicles with air conditioner:

Warning!

The air conditioning system refrigerant circuit must not be opened.

|

|

|

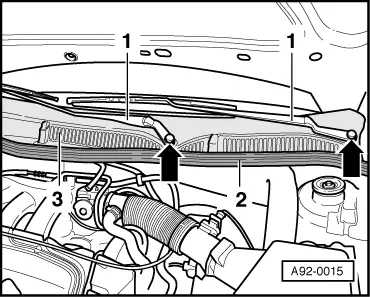

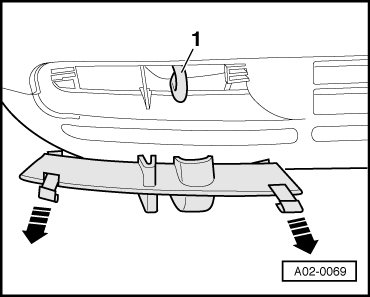

Note: Use adhesive tape to prevent scratching bumper. |

|

|

|

|

|

|

|

|

Note: The flexible pipe connection (de-coupling element) on the front exhaust pipe must not be bent more than 10 °- otherwise it can be damaged.

|

|

|

|

|

|

|

|

Note: Use adhesive tape to prevent scratching bumper.

|

|

|

|

|

|

Note: Use step ladder VAS 5085 for access to engine compartment from above. |

|

|

|

|

|

Notes:

|