|

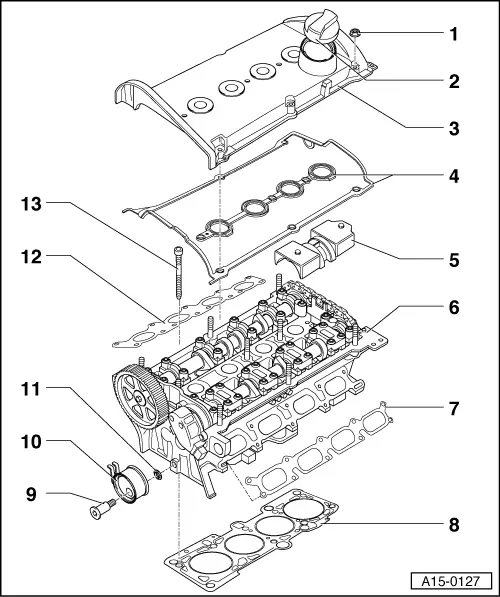

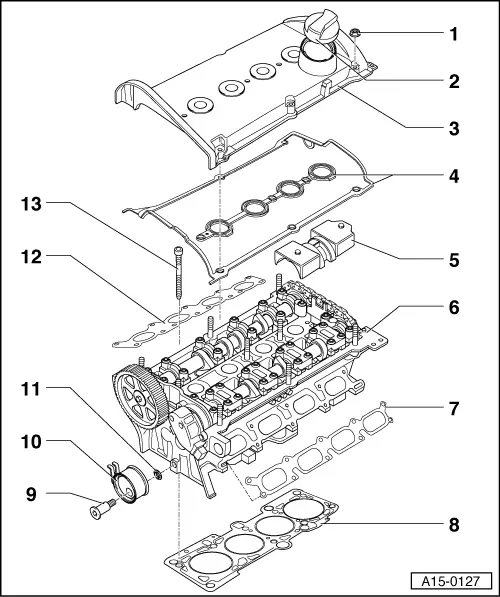

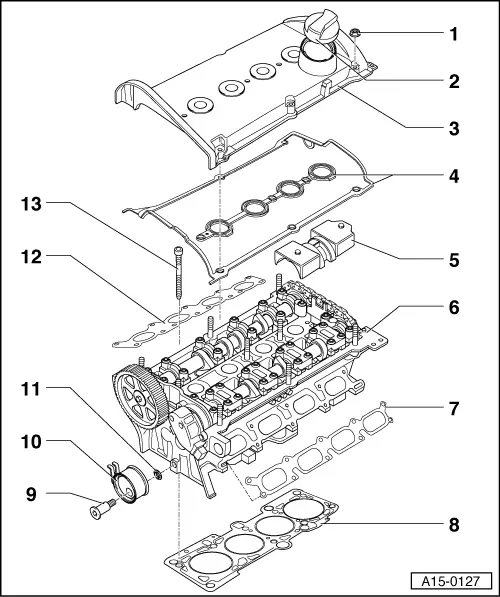

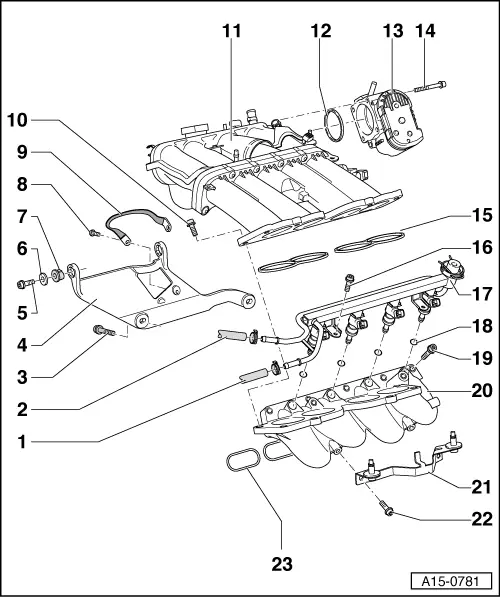

Removing and installing cylinder head

Removing and installing cylinder head

Notes:

-

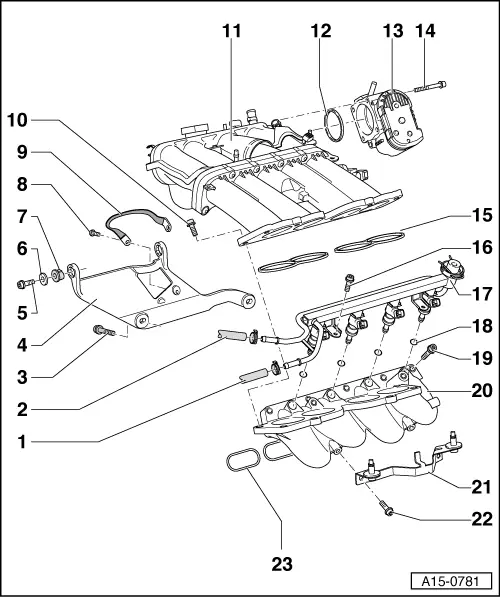

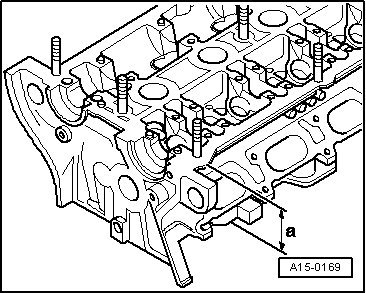

◆ The following procedures are described for vehicles with electronic throttle, secondary air system and exhaust gas recirculation system. The procedures for older vehicles without these features are the same, except that some of the steps will not be required.

-

◆ Renew the cylinder head bolts.

-

◆ When performing repairs, renew seals, gaskets, self-locking nuts and bolts which have a specified tightening angle.

-

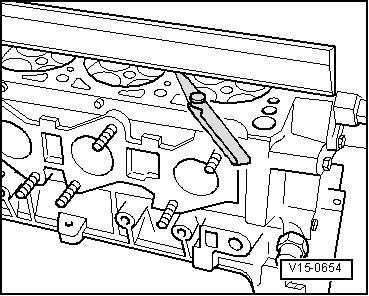

◆ When installing an exchange cylinder head with the camshafts fitted, the contact surfaces between bucket tappet and cam running surface must be oiled after installation of the cylinder head.

-

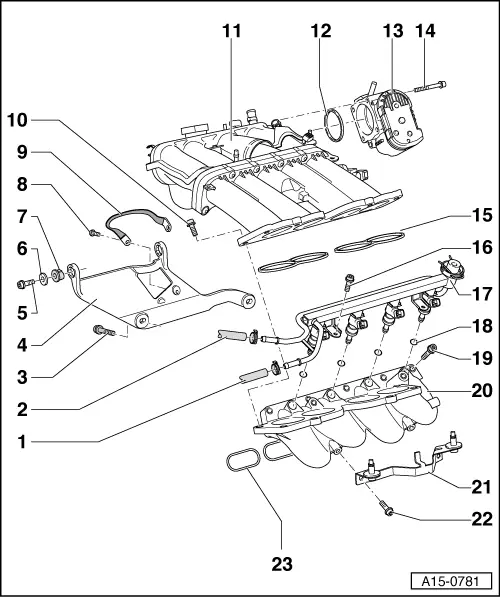

◆ The plastic protectors fitted to protect the open valves must only be removed immediately before fitting the cylinder head.

-

◆ When fitting a new cylinder head or cylinder head gasket, drain off all the old coolant and re-fill with new coolant.

-

◆ Cylinder heads which have cracks between the valve seats or between valve seat inserts and the spark plug thread can be used further without reducing service life, provided the cracks do not exceed a maximum of 0.3 mm in width, or when no more than the first 4 turns of the spark plug threads are cracked.

|