A3 Mk1

|

Servicing tandem pump

Removing and installing tandem pump

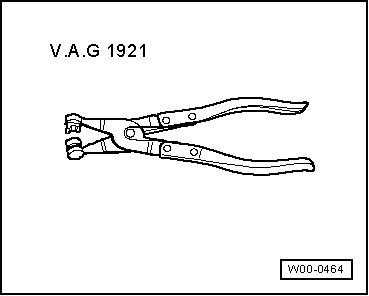

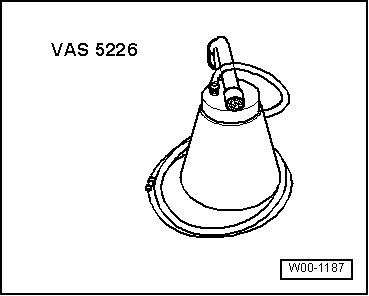

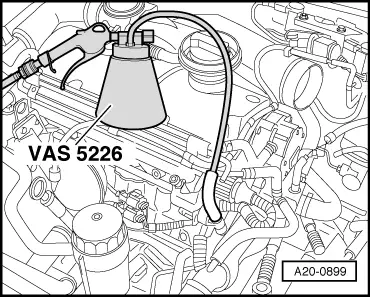

Special tools and workshop equipment required |

|

|

or

|

|

|

or

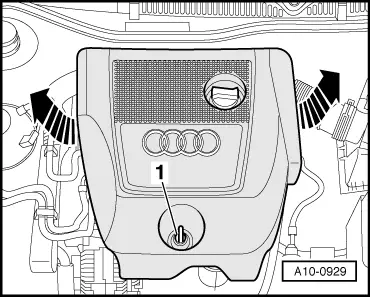

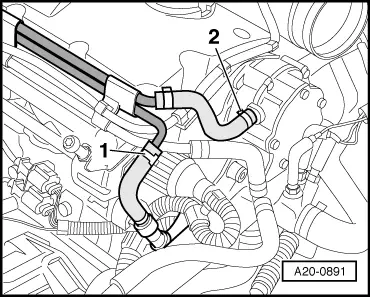

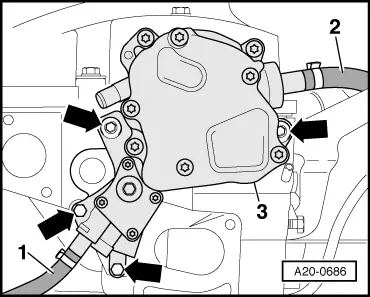

Observe rules for cleanliness . Removing |

|

|

Warning

|

|

|

|

|

|

Notes:

|

|

|

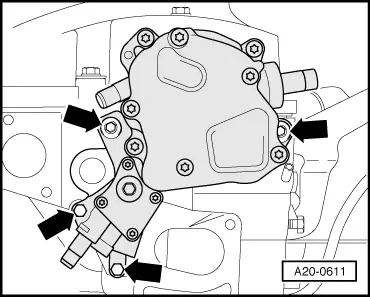

Installing Install in reverse sequence; note the following points: Notes: |

|

|

|