A3 Mk1

|

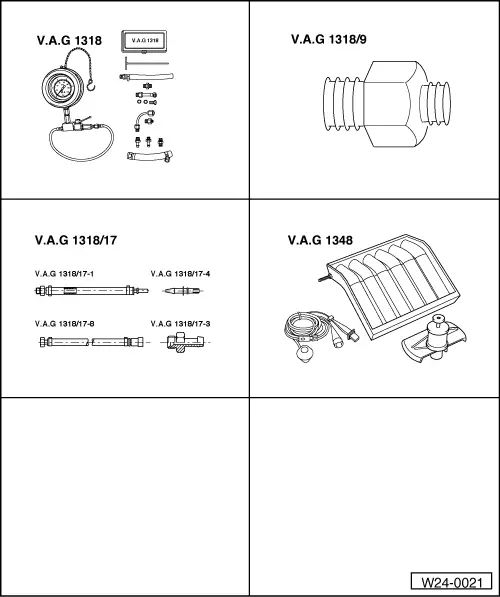

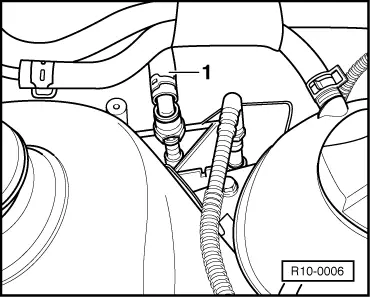

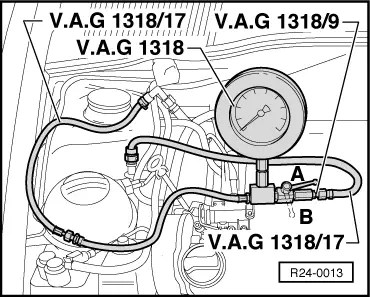

Checking components

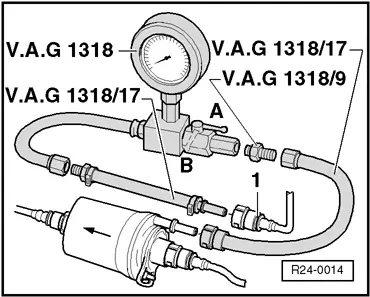

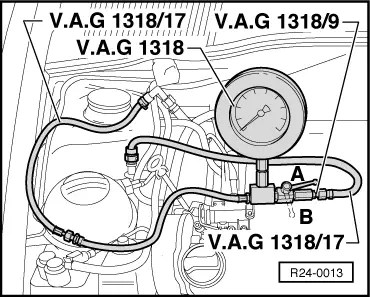

Checking fuel pressure regulator and holding pressure

|

|

|

Note: To do this, press buttons together on hose coupling. |

|

|

If the specification is obtained:

If the specification is not obtained:

If no kinks are found:

If the specification is not obtained:

|

|

|

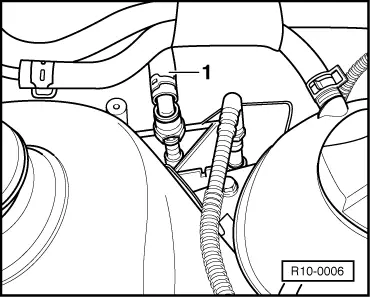

Warning!

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

Note: Press buttons on hose couplings to do this.

If the specification is not obtained:

If the specification is obtained:

If the specification is not obtained:

=> Repair group 15; Removing and installing fuel delivery unit. Check for leaks and holding pressure

If the holding pressure drops below 2 bar:

|

|

|

If the pressure drops again:

If the pressure does not drop:

=> Repair group 20; Removing and installing parts of fuel system; checking fuel pump If the non-return valve is OK:

Note: Before removing pressure gauge place a cloth around the connections to be loosened. |