A3 Mk1

|

Engine control unit

Engine control unit

The following procedure applies to engine control unitsnot fittedwith a protective metal casing. For engine control unitswithprotective metal casing, refer to=>Page 24-110 . Removing |

|

|

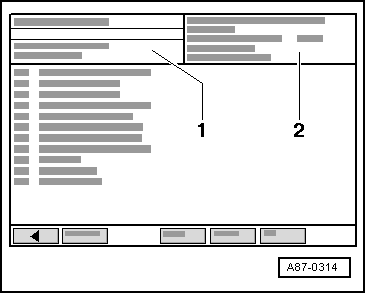

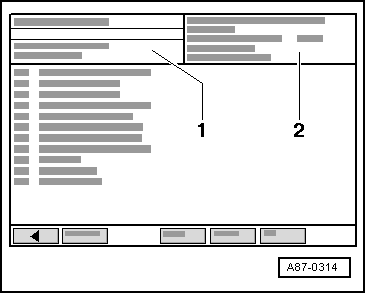

→ The display on vehicle diagnostic, test and information system VAS 5051 will show the control unit identification and the coding -2-.

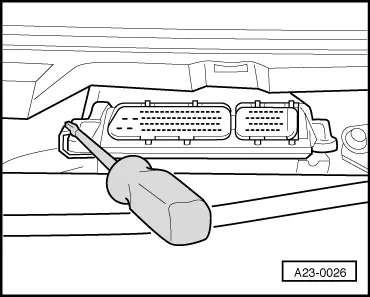

Note: Always make sure that the ignition is switched off before unplugging or fitting the connectors for the engine control unit.

|

|

|

→ The display on vehicle diagnostic, test and information system VAS 5051 will show the control unit identification and the coding -2-.

|

|

|

|

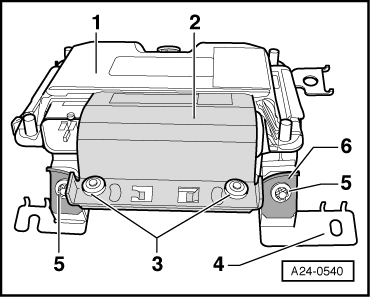

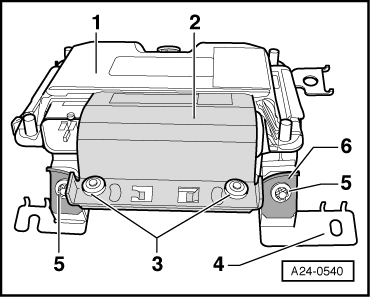

Note: Item -1- in the illustration shows the engine control unit with protective metal casing. |

|

|

|

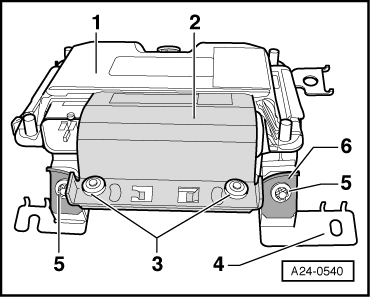

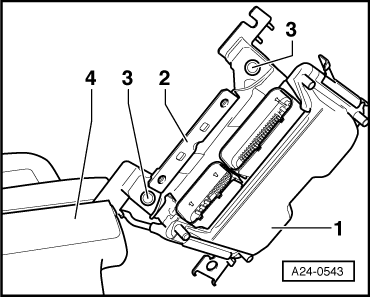

→ As a deterrent against unauthorised access to the connectors on the engine control unit, the control unit -1- is bolted to a metal casing -4- by means of shear bolts -3- and a locking plate -2-. The threads of the shear bolts are additionally coated with a thread-locking compound to make them more difficult to remove. In order to unplug the connectors from the engine control unit (for instance when connecting the test box or replacing the engine control unit), the locking plate -2- must be separated from the protective casing. The required procedure is described below: |

|

|

|

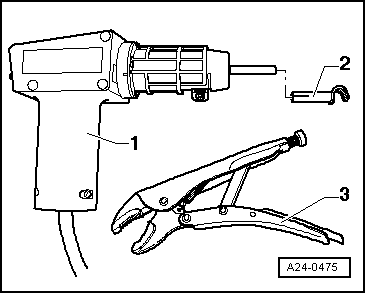

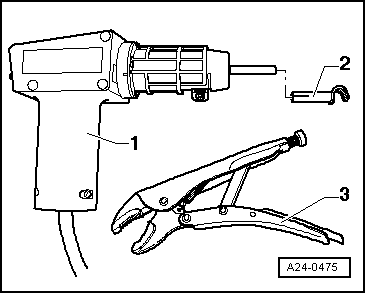

The following tools are required:

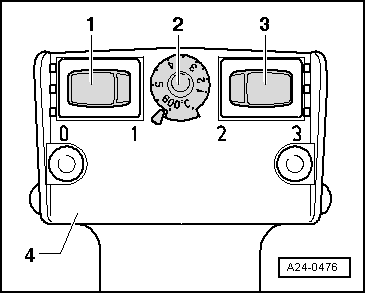

Procedure: Caution

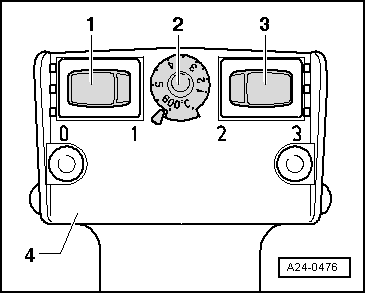

Keep exactly to the following procedure to avoid damage (burning) to the wiring, connectors, insulation or the control units. Follow the operating instructions supplied with the hot-air blower. |

|

|

|

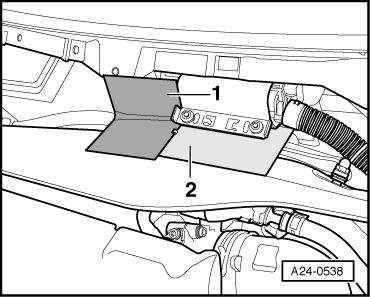

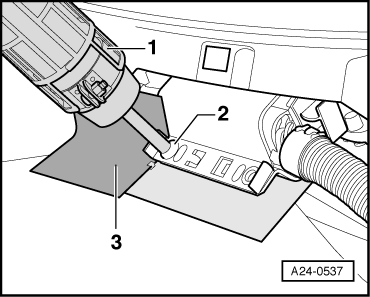

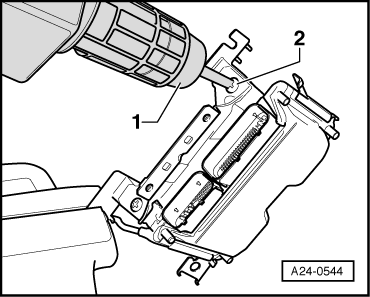

→ To avoid damage to wiring or connectors, use heat shields (Items -1- and -2-, consisting of metal plates). |

|

|

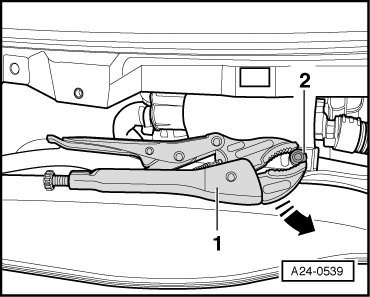

Note: In the next step the blower is used to heat the shear bolt in the locking plate. This reduces the effect of the thread-locking compound so the bolts can then be removed more easily. Warning

When the threads in the locking plate are heated up, this also heats the shear bolts and parts of the metal casing. Take care not to burn your hands. Also make sure that, as far as possible, you only apply heat to the threads and not to the adjacent parts. Cover these up if necessary. |

|

|

Note: Be particularly careful here because the control unit connectors are very close to this bolt.

|

|

|

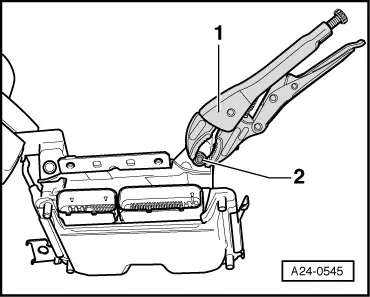

Repeat the procedure for the second shear bolt. Be particularly careful here because the control unit connectors are very close to this bolt.

|

|

|

|

Caution

Do not pull the control unit over the locking plate -6-; this would exert excessive force on the control unit housing and could cause damage.

With the control unit removed from the vehicle, the locking plate must now be unbolted from the casing. The locking plate must be removed before pulling out the control unit. |

|

|

|

→ As a deterrent against unauthorised access to engine control unit -1-, locking plate -2- is bolted to the metal casing by means of shear bolts -3-. The threads of the shear bolts are additionally coated with a thread-locking compound to make them more difficult to remove.

|

|

|

|

The following tools are required:

Procedure: Caution

Keep exactly to the following procedure to avoid damage (burning) to the wiring, connectors, insulation or the control units. Follow the operating instructions supplied with the hot-air blower. |

|

|

Note: In the next step the blower is used to heat the shear bolt in the locking plate. This reduces the effect of the thread-locking compound so the bolts can then be removed more easily. Warning

When the threads in the locking plate are heated up, this also heats the shear bolts and parts of the metal casing. Take care not to burn your hands. Also make sure that, as far as possible, you only apply heat to the threads and not to the adjacent parts. Cover these up if necessary. |

|

|

|

|

|

Repeat the procedure for the second shear bolt. The engine control unit can now be separated from the metal casing.

Installing Installation is performed in the reverse sequence: install metal casing (with locking plate) on engine control unit. Use new shear bolts. The following steps need to be performed after connecting the new engine control unit:

For this step use vehicle diagnostic, testing and information system VAS 5051. |